Download PDF

Streamlining Agricultural Automation with Eaton’s Package Solution

Technology Category

- Automation & Control - Human Machine Interface (HMI)

- Sensors - Electrical Conductivity Sensors

Applicable Industries

- Agriculture

- Packaging

Applicable Functions

- Maintenance

- Product Research & Development

Use Cases

- Leasing Finance Automation

- Material Handling Automation

Services

- System Integration

- Training

The Challenge

Grossi Electric, a full-service electrical contracting company, was tasked with facilitating the hulling, dehydrating, and preparation processes at a walnut processing plant in Waterford, California. The company aimed to explore innovative options for creating cleaner and more efficient control panels that would eliminate the intensive time, labor, and costs associated with excessive point-to-point wiring. As a rapidly growing electrical contracting company, Grossi Electric was also concerned about managing risk and cost while attempting to establish a new and unfamiliar service offering in a mature market for control products. The walnut processing plant presented a prime learning opportunity for the company to discover the best way to build more tailored control panels for its customers. The challenge was to enable a lean automation process that was smarter, simpler, more effective, and of unique advantage for clients.

The Customer

Grossi Electric, Inc.

About The Customer

Grossi Electric Inc. is a full-service electrical contracting company that specializes in industrial and commercial construction, automation services, and computer-aided design and planning. The company’s services traditionally place emphasis on achieving safety and efficiency in electrical construction combined with user-friendly lean automation solutions. The company was interested in expanding their services into lean agricultural automation systems—intelligently controlled electrical projects capable of supporting all aspects of agricultural materials handling, including everything from plant processing to food preparation and packaging.

The Solution

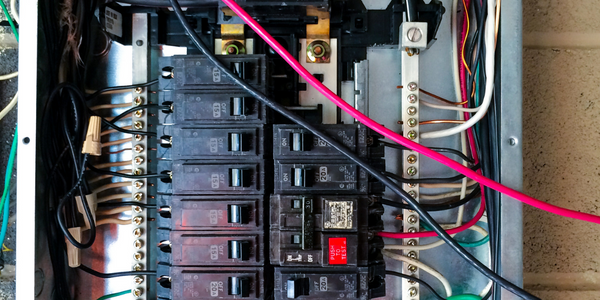

Grossi Electric, in collaboration with Eaton, designed and implemented an automated walnut huller and dehydrator control system using a complete package of Eaton SmartWire-enabled products. By combining Eaton products into a total package solution, Grossi was able to design a very affordable and cost-effective control system for the walnut processing plant. SmartWire-DT enabled the control panels to be built more quickly, with greater reliability, and without adding excess parts and wires. The cleaner design of the Eaton products also reduced the overall enclosure footprint. The resulting walnut huller / dehydration control system leveraged SmartWire products for lean automation and labor savings; soft starters; motor protectors; power supplies; circuit breakers; and the Visual Designer software tool running on an Eaton XP-503 touchscreen control interface. Ninety-five percent of the resulting SmartWire configuration consisted of Eaton control panels.

Operational Impact

Quantitative Benefit

Related Case Studies.

Case Study

Intelligent Farming with ThingWorx Analytics

Z Farms was facing three challenges: costly irrigation systems with water as a limited resource, narrow optimal ranges of soil moisture for growth with difficult maintenance and farm operators could not simply turn on irrigation systems like a faucet.

Case Study

Greenhouse Intelligent Monitoring and Control Solution

Farming Orchids is the most successful form of precision farming in Taiwan, and also the most exported flower. Orchids need a specific temperature and humidity conditions to grow and bloom, and its flowering time may not be in line with market demands, so the price collapses when there is overproduction. Therefore, some farmers began to import automated greenhouse control systems for breeding and forcing, which not only improves quality, but also effectively controls the production period and yield to ensure revenue. In 2012, an orchid farmer built a Forcing Greenhouse of about 200 pings (approximately 661 Square Meters) in Tainan, Taiwan. The system integrator adopted Advantech’s APAX-5000 series programmable automation controllers to build the control platform, coupled with Advantech WebAccess HMI/SCADA software, to achieve cloud monitoring. The staff of the orchid field can monitor important data anytime via smart phone, iPad, and other handheld devices, and control the growth and flowering conditions. System requirements: In the past, most environmental control systems of orchid greenhouses in Taiwan used PLCs (Programmable Logic Controller) with poorscalability and control, and could not be connected to the Internet formonitoring from the cloud. For advanced database analysis and networking capability, the PC platform must be adopted. Therefore, PAC Systems (Programmable Automation Controller) with both PLC programming capabilities andPC functions is a better choice.The environmental control of the Orchid greenhouse switches on and off devices like fan, shade net, cooling/heat pump, liquid flow control, water-cooling wall etc. It is controlled by a control panel of electric controllers, and is driven by a motor, to adjust the greenhouse temperature, humidity, and other environmental conditions to the set parameters.

Case Study

Enabling Internet of Things Innovation in Agriculture

DigiBale, wanted to apply technology know-how and IP from implementations successfully to more agriculture sectors including cotton, forestry, sugarcane and cattle. However, farmers and growers still have worries about the connected technology.

Case Study

Precision beekeeping with wireless temperature monitoring

Honeybees are insects of large economic value and provide a vital service to agriculture by pollinating a variety of crops. In addition, bees provide us with valuable products such as honey, beeswax, propolis, bee venom, etc. Monitoring of honeybee colony health, population, productivity, and environmental conditions affecting the colony health have always been exceedingly difficult tasks in apiculture. Research has shown that even small deviations (by more than 2°C) from the optimal temperatures have a significant influence on the development of the brood and the health of adult bees.