Case Studies.

Our Case Study database tracks 18,927 case studies in the global enterprise technology ecosystem.

Filters allow you to explore case studies quickly and efficiently.

-

(5,794)

- (2,602)

- (1,765)

- (764)

- View all

-

(5,073)

- (2,519)

- (1,260)

- (761)

- View all

-

(4,407)

- (1,774)

- (1,292)

- (480)

- View all

-

(4,158)

- (2,048)

- (1,256)

- (927)

- View all

-

(2,488)

- (1,262)

- (472)

- (342)

- View all

- View all 15 Technologies

- (1,732)

- (1,626)

- (1,605)

- (1,461)

- (1,423)

- View all 42 Industries

- (5,782)

- (4,114)

- (3,091)

- (2,780)

- (2,671)

- View all 13 Functional Areas

- (2,568)

- (2,482)

- (1,866)

- (1,561)

- (1,537)

- View all 127 Use Cases

- (10,333)

- (3,499)

- (3,392)

- (2,982)

- (2,593)

- View all 9 Services

- (503)

- (432)

- (382)

- (301)

- (246)

- View all 737 Suppliers

Selected Filters

18,927 case studies

|

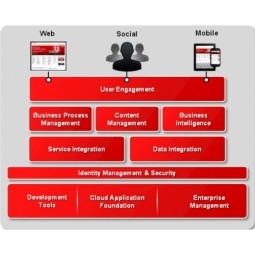

Fusion Middleware Integration on Cloud for Pharma Major

Cognizant

Customer wanted a real-time, seamless, cloud based integration between the existing on premise and cloud based application using SOA technology on Oracle Fusion Middleware Platform, a Contingent Worker Solution to collect, track, manage and report information for on-boarding, maintenance and off-boarding of contingent workers using a streamlined and Integrated business process, and streamlining of integration to the back-end systems and multiple SaaS applications.

|

|

Coca Cola Swaziland Conco Case Study

AVEVA

Coco Cola Swaziland, South Africa would like to find a solution that would enable the following results: - Reduce energy consumption by 20% in one year. - Formulate a series of strategic initiatives that would enlist the commitment of corporate management and create employee awareness while helping meet departmental targets and investing in tools that assist with energy management. - Formulate a series of tactical initiatives that would optimize energy usage on the shop floor. These would include charging forklifts and running cold rooms only during off-peak periods, running the dust extractors only during working hours and basing lights and air-conditioning on someone’s presence. - Increase visibility into the factory and other processes. - Enable limited, non-intrusive control functions for certain processes.

|

|

Driving Digital Transformations for Vitro Diagnostic Medical Devices

Microsoft

Diagnostic devices play a vital role in helping to improve healthcare delivery. In fact, an estimated 60 percent of the world’s medical decisions are made with support from in vitrodiagnostics (IVD) solutions, such as those provided by Roche Diagnostics, an industry leader. As the demand for medical diagnostic services grows rapidly in hospitals and clinics across China, so does the market for IVD solutions. In addition, the typically high cost of these diagnostic devices means that comprehensive post-sales services are needed. Wanteed to improve three portions of thr IVD:1. Remotely monitor and manage IVD devices as fixed assets.2. Optimizing device availability with predictive maintenance.3. Recommending the best IVD solution for a customer’s needs.

|

|

KINESYS Semiconductor Factory Automation Software

WIBU-SYSTEMS

KINESYS Software provides both Integrated Device Manufacturer (IDM) and Original Equipment Manufacturer (OEM) customers world-class software products and solutions for advanced wafer and device traceability and process management. KINESYS offers state of the art database technology with a core focus on SEMI standards. KINESYS’ challenge was to make back-end processing failure-free and easy to use for clients while supporting licensing models more adaptable to changing industry needs.

|

|

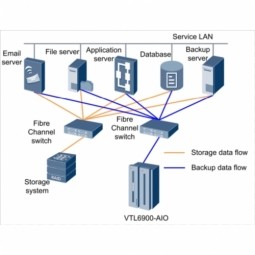

New Backup System Solves Legacy Problems

Huawei

Midea's outdated IT infrastructure in some sites could no longer keep pace with company's growth, putting operational reliability at risk. The legacy data backup system could not backup at some production sites. Some sites were still using the x86 server’s local hard disks as the backup media, resulting in limited backup size. The existing backup system was inefficient.

|

|

Developing Smart Tools for the Airbus Factory

NI

Manufacturing and assembly of aircraft, which involves tens of thousands of steps that must be followed by the operators, and a single mistake in the process could cost hundreds of thousands of dollars to fix, makes the room for error very small.

|

|

Wireless Improves Efficiency in Compressed Air Systems

Adaptive Wireless Solutions

Hollingsworth and Vose wanted to improve the efficiency of their compressed air system, lower the electricity expense component of manufacturing cost in their commodity industry, and conserve energy leading to lowered greenhouse gas emissions. Compressed air systems degrade over time and become leaky and inefficient. Hollingsworth and Vose wanted to increase the frequency of system inspections without paying the high cost of manual labor.

|

|

Temperature Monitoring for Restaurant Food Storage

Enviromon

When it came to implementing a solution, Mr. Nesbitt had an idea of what functionality that he wanted. Although not mandated by Health Canada, Mr. Nesbitt wanted to ensure quality control issues met the highest possible standards as part of his commitment to top-of-class food services. This wish list included an easy-to use temperature-monitoring system that could provide a visible display of the temperatures of all of his refrigerators and freezers, including historical information so that he could review the performance of his equipment. It also had to provide alert notification (but email alerts and SMS text message alerts) to alert key staff in the event that a cooling system was exceeding pre-set warning limits.

|

|

Minimizing Downtime through Predictive Asset Monitoring

Digi

It is not a matter if a hydraulic hose will fail, but a matter of when. When hydraulic hoses fail on a garbage truck or on heavy machinery, Eaton's customers spend millions of dollars on hydraulic fluid cleanup, fines, remote service and medical costs that result from injuries.

|

|

Bridge monitoring in Hamburg Port

Worldsensing

Kattwyk Bridge is used for both rail and road transport, and it has played an important role in the Port of Hamburg since 1973. However, the increasing pressure from traffic requires a monitoring solution. The goal of the project is to assess in real-time the bridge's status and dynamic responses to traffic and lift processes.

|

|

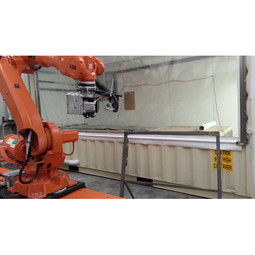

ABB Robot Calibration

RoboDK

The company manufactures marina products through robot milling but observed important errors in the surface quality of their machined parts. It uses an ABB IRB 6640-130/3.2 robot, which has 130 kg payload, 3.2 m reach, 0.050 mm repeatability, and was not factory calibrated. On top of that, the robot is placed on a linear track, which introduces yet another source of errors.

|

|

IoT Data Analytics Case Study - Packaging Films Manufacturer

Altizon Systems

The company manufactures packaging films on made to order or configure to order basis. Every order has a different set of requirements from the product characteristics perspective and hence requires machine’s settings to be adjusted accordingly. If the film quality does not meet the required standards, the degraded quality impacts customer delivery causes customer dissatisfaction and results in lower margins. The biggest challenge was to identify the real root cause and devise a remedy for that.

|

|

Accelerate Production for Spirit AeroSystems

SAP

The manufacture and assembly of massive fuselage assemblies and other large structures generates a river of data. In fact, the bill of materials for a single fuselage alone can be millions of rows of data. In-house production processes and testing, as well as other manufacturers and customers created data flows that overwhelmed previous processes and information systems. Spirit’s customer base had grown substantially since their 2005 divestiture from Boeing, resulting in a $41 billion backlog of orders to fill. To address this backlog, meet increased customer demands and minimize additional capital investment, the company needed a way to improve throughput in the existing operational footprint. Spirit had a requirement from customers to increase fuselage production by 30%. To accomplish this goal, Spirit needed real-time information on its value chain and workflow. However, the two terabytes of data being pulled from their SAP ECC was unmanageable and overloaded their business warehouse. It had become time-consuming and difficult to pull aggregate data, disaggregate it for the needed information and then reassemble to create a report. During the 6-8 hours it took to build a report, another work shift (they run three per day) would have already taken place, thus the report content was out-of-date before it was ever delivered. As a result, supervisors often had to rely on manual efforts to provide charts, reports and analysis.

|

|

Hydro One Leads the Way In Smart Meter Development

Trilliant

In 2010, Ontario’s energy board mandated that time-of-use (TOU) pricing for consumers be available for all consumers on a regulated price plan. To meet this requirement, Hydro One needed to quickly deploy a smart meter and intelligent communications network solution to meet the provincial government’s requirement at a low cost. The network needed to cover Hydro One’s expansive service territory, which has a land mass twice the size of Texas, and its customers live in a mix of urban, rural, and remote areas, some places only accessible by air, rail, boat or snowmobile. Most importantly, the network needed to enable future enterprise-wide business efficiencies, modernization of distribution infrastructure and enhanced customer service. To meet these needs, Hydro One conceptualized an end-to-end solution leveraging open standards and Internet Protocols (IP) at all communication levels. The utility drew upon industry leaders like Trilliant to realize this vision.

|

|

Underground Mining Safety

The goal was to produce a safety system to monitor and support underground mining operations; existing systems were either too simple (i.e. phone line) or overly complex and expensive, inhibiting deployment, and providing little-to-no support in event of an accident. Given the dangerous nature of the mining work environment and the strict regulations placed on the industry, the solution would have to comply with Mine Safety and Health Administration (MSHA) regulations. Yet the product needed to allow for simple deployment to truly be a groundbreaking solution - increasing miner safety and changing daily operations for the better.

|

|

Driving Predictive Maintenance into ThyssenKrupp Elevators

CGI

TKE had a number of initiatives underway around the world to enable remote monitoring of its elevators. However, none of the solutions provided the data and insight required to move from a traditional reactive maintenance approach to one that is predictive and even preemptive, and all were challenged by information overload issues that limited their value. TKE wanted a solution that would enable it to anticipate and quickly resolve maintenance issues for the majority of the 1.2 million elevators it services across the globe.

|

|

Use IoT to Improve Healthcare Business Outcomes

ThingWorx

Before developing an IoT solution, ICURO hit a major roadblock with its healthcare platform. Limited data sharing between healthcare providers and insurance companies impeded effective communication, resulting in frequent duplication of efforts and making it difficult for each entity to deliver better care while maintaining reasonable costs. ICURO wanted to resolve these data sharing issues, they started developing tools and systems that connect products in meaningful ways, enabling both entities to collaborate more effectively.

|

|

Mueller moves from preventive to predictive maintenance

Augury

Recognizing the recent advances in and affordability of predictive maintenance (PdM), the company decided to implement a PdM program in one of its facilities on a trial basis. Anticipating positive results, we hope to gradually pursue wider implementation.

|

|

Monitoring of Pressure Pumps in Automotive Industry

Elmodis

A large German/American producer of auto parts uses high-pressure pumps to deburr machined parts as a part of its production and quality check process. They decided to monitor these pumps to make sure they work properly and that they can see any indications leading to a potential failure before it affects their process.

|

|

Enabling Connectivity across a Dispersed Landscape

Cisco

North West Redwater (NWR) intended to build, manage and operate a new bitumen refinery. The new refinery was being built across six square kilometers and would include over 100 contracting companies participating in the construction phase of the project. NWR wanted to provide connectivity to the 100 contracting companies over a dispersed remote area in order to simplify the contractor onboarding process, decrease operating costs, and control the project schedule.

|

|

Driven by Data

Siemens

Digitalization starts with the design of a product. Maserati needs to virtually create, simulate, and test their cars in a time efficient manner. The Maserati engineers needed to manage their project collaboratively across various locations.

|

|

HaemoCloud Global Blood Management System

Bright Wolf

1) Deliver a connected digital product system to protect and increase the differentiated value of Haemonetics blood and plasma solutions. 2) Improve patient outcomes by increasing the efficiency of blood supply flows. 3) Navigate and satisfy a complex web of global regulatory compliance requirements. 4) Reduce costly and labor-intensive maintenance procedures.

|

|

Zonar Takes the Wheel with a M2M Solution

AT&T

Zonar’s fleet management solutions collect, report and analyze data before, during and after a vehicle’s trip. The company needed Machine-to-Machine (M2M) connectivity to enable communication between in-vehicle devices and back-end systems. To deliver high volumes of potentially sensitive information from and to moving vehicles – and keep pace with its rapid business growth – Zonar wanted a highly secure solution that it could easily manage and that had the required national and global reach.

|

|

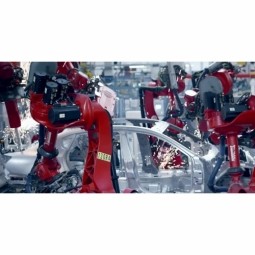

Carmaker Holds the Keys to Network Security

Huawei

FAW-Volkswagen Automotive Company (FAW-VW) required a high number of communication terminals due to its rapid development. FAW-VW also faced challenges in security management, IT Operation and Maintenance (O&M) costs, and employees work efficiency. FAW-VW needed terminal security protection with reliable access control and user rights management and comprehensive network protection.

|

|

Digital Retail Security Solutions

ThingLogix

Sennco wanted to help its retail customers increase sales and profits by developing an innovative alarm system as opposed to conventional connected alarms that are permanently tethered to display products. These traditional security systems were cumbersome and intrusive to the customer shopping experience. Additionally, they provided no useful data or analytics.

|

|

Controlling water levels in canals with LoRa

SmartLog

A circuit of the small inland waterways and canals with stops at the numerous quays is a so-called ‘must do’ for tourists as they say. For municipalities or canal authorities however, it is of great importance to have insight in the water level of these canals to prevent them from flooding. To gain more insight in the water level of the canals, the Ministry of Infrastructure uses sensors with RS232 protocols. Since this technology is quite an old-fashioned one, it is not suited for controlling the water level from several canals real-time from distance.

|

|

Pump Cavitation Detection

FogHorn

Cavitation is a condition can occur in centrifugal pumps when there is a sudden reduction in fluid pressure. Pressure reduction lowers the boiling point of liquids, resulting in the production of vapor bubbles if boiling occurs. This is more likely to happen at the inlet of the pump where pressure is typically lowest. As the vapor bubbles move towards the outlet of the pump where pressure is higher, they rapidly collapse (return to a liquid state) resulting in shock waves that can damage pump components.

|

|

IIC - Time Sensitive Networking (TSN) Testbed

B&R Industrial Automation

Manufacturing operations requires tight coordination of sensing and actuation to safely and efficiently perform closed loop control. Typically these systems have been deployed using non-standard network infrastructure or air-gapped (unconnected) standard networks. This approach leaves devices and data much harder to access and creates a technical barrier to IIoT which is predicated on the ability to consume data anywhere throughout the infrastructure.

|

|

Remote Cold Chain Monitoring Solution

Stellapps Technologies

Challenges like Sub-standard quality milk because of not chilling at appropriate temperature by Operator & also differences in milk volume between procurement and chilling, at chilling center level and collection center level.

|

|

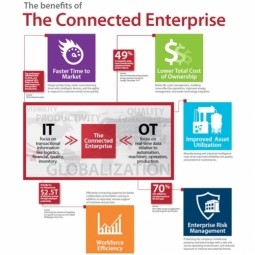

The Connected Enterprise Optimizes Facilities and Supplier Networks

Rockwell Automation

Rockwell wanted to implement flexible and agile global MES for diverse product portfolio and a variety of manufacturing processes and replace individual ERP systems and custom application with a standardized system that spans all plants.

|