Download PDF

Accelerating Time-to-Market: Volvo Trucks North America's Digital Transformation with Digizuite

Technology Category

- Networks & Connectivity - 5G

- Platform as a Service (PaaS) - Application Development Platforms

Applicable Industries

- E-Commerce

- Life Sciences

Applicable Functions

- Logistics & Transportation

- Sales & Marketing

Use Cases

- Last Mile Delivery

- Time Sensitive Networking

The Challenge

Volvo Trucks North America, a division of Volvo Group Trucks, faced significant marketing challenges despite its established reputation. The company struggled with internal collaboration gaps and communication issues with its dealer network, which hindered its sales potential. The IT department was also burdened with the time-consuming task of preparing images for their eCommerce platform, which facilitates aftermarket parts sales. These communication and information gaps, along with other logistical challenges, prevented Volvo Trucks teams across the North American organization from reaching their full sales and profit potential.

About The Customer

Volvo Trucks North America is the North American division of Volvo Group Trucks, the truck manufacturing operation of Volvo. The company manufactures a wide spectrum of highway and vocational class 8 vehicles and supports new and used Volvo trucks through a dealer network, as well as leading parts and service programs. Headquartered in Greensboro, NC, Volvo Trucks North America has over 10,000 employees and generates a revenue of approximately $900 million USD.

The Solution

To address these challenges, Volvo Trucks North America implemented the Digizuite DAM (Digital Asset Management) at the end of 2019, integrating it with the Sitecore CMS (Content Management Solution). This technology provided the necessary tools for speedy content production and distribution, enabling marketers to efficiently distribute marketing assets to the entire dealer network. The Digizuite DAM served as a centralized branding and media library, making it easy and fast to get updated content into the hands of sales representatives. The platform also automated the watermarking and image formatting processes, saving countless man hours every month and reducing the time to display all parts available for purchase on the PartsAsist site.

Operational Impact

Quantitative Benefit

Related Case Studies.

Case Study

Corporate Identity Solution Adds Convenience to Beckman Coulter

Beckman Coulter wanted to implement a single factor solution for physical and remote logical access to corporate network. Bechman Coulter's users were carrying smart card badges for doors, but also needed a one-time password token to access to our corporate network when they were not in the office. They wanted to simplify the process.

Case Study

Embracing Business Success in Real Time

· Increase control over growing Big Data to improve business decisions · Manage data for 28,000 biotechnology stockkeeping units in the fields of microbiology, molecular biology, animal cell cultures, plant tissue cultures, and lab ware for laboratory chemicals · Accelerate report generation and analysis with real-time data

Case Study

Digital Transformation of Atlanta Grout & Tile: An IoT Case Study

Atlanta Grout & Tile, a Tile, Stone & Grout restoration company based in Woodstock, Georgia, was facing challenges with its traditional business model. Despite steady growth over the years, the company was falling behind the web revolution and missing out on the opportunity to tap into a new consumer base. They were using independent software from different vendors for each of their department information and workforce management. This resulted in a lot of manual work on excel and the need to export/import data between different systems. This not only increased overhead costs but also slowed down their response to clients. The company also had to prepare numerous reports manually and lacked access to customer trends for effective business decision-making.

Case Study

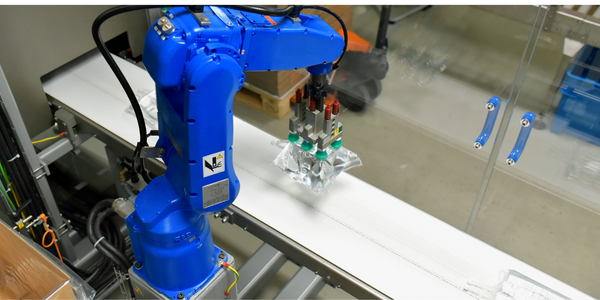

Flow Robotics: Scaling Up Production and Accelerating Product Development with IoT

Flow Robotics, a Danish manufacturer, developed flowbot™ ONE pipetting robots to alleviate the strain on bioanalysts in life-science laboratories and hospitals across Europe. These robots were designed to automate part of the testing process, speeding up the time it takes to produce results and reducing pressure on staff. However, the company faced challenges in scaling up production and accelerating product development. High workloads and physically challenging conditions have long been an issue for laboratory professionals. Flow Robotics estimates that around half of medical lab technicians carry out the same arm movements for at least a quarter of their working day. The American Society for Clinical Pathology reported that 85% of laboratory professionals feel burnt out; 36% struggle with inadequate staffing; and 32% face a heavy workload and pressure to complete all testing on time.

Case Study

IFFCO Boosts IT Performance and Innovates Agriculture with Oracle Cloud

Indian Farmers Fertiliser Cooperative Ltd. (IFFCO), the world’s largest manufacturer and marketer of fertilizers in the cooperative sector, was facing several challenges in its quest to innovate and improve the livelihood of farmers in India. The organization had recently launched a new product, nano urea, which brought new demands to IFFCO’s cloud computing needs. The organization needed a reliable cloud vendor to support the processes of 6–7 new manufacturing plants during the upcoming year, enhancing its production capability 300–350 million bottles of nano urea to meet increasing demand. IFFCO’s cloud adoption was driven by a need to innovate. The organization wanted capabilities for a dynamic business that can adapt to the changing needs of the market while growing fast. However, it was inhibited by rigid on-premises data center deployments and the overhead of maintaining legacy systems. IFFCO wanted to apply the elasticity and availability of cloud for improving overall performance of applications at lowest possible operational overhead. Lastly, IFFCO needed to provide the benefits of its technology to all its stakeholders, including employees, members, transporters, and farmers, some of whom have limited literacy. To accommodate all stakeholders, IFFCO wanted to add a voice interface to its applications.

Case Study

Revolutionizing Aerospace Industry with 3D Printing: A 63% Lighter Titanium Part

GE Aviation, a renowned name in the aerospace industry, recognized the potential of 3D printing technology in transforming the sector. The primary challenge was to reduce the weight of the aerospace parts, which would directly impact the fuel costs. A lighter airplane would mean lower fuel consumption, leading to cost savings and a smaller carbon footprint. However, achieving this weight reduction without compromising the strength and functionality of the parts was a significant challenge. Traditional manufacturing methods were not able to provide the desired weight reduction while maintaining the required stiffness and strength of the parts. The challenge was to find a solution that could create strong, light, and functional aerospace parts.