Anaren Microwave Implements their manufacturing CMMS

- Functional Applications - Computerized Maintenance Management Systems (CMMS)

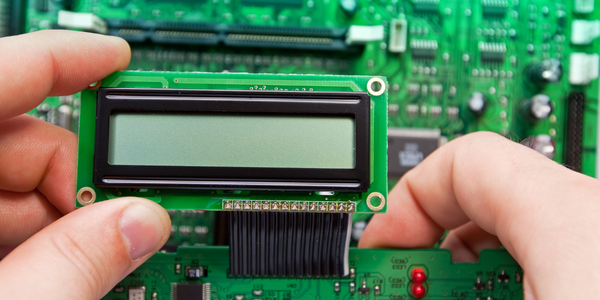

- Electronics

Like many organizations, Anaren had a homegrown work order application that had basic asset management functionality. “It was menu driven, so quite cumbersome,” explained Bill, “reporting was limited and it still relied heavily on paper transactions and records. We looked at our business needs going forward and decided this was one area that could be modernized.” On launching the Manufacturing CMMS project, Bill, the business analyst of the company identified three major areas for improvement:

1. Improve efficiency by eliminating paper.

2. Improve the control of preventive maintenance.

3. Improve inventory management.

“We learned about Fiix from one of our subsidiaries, and when we tried it we liked it immediately,” recalls Bill. “We wanted an application that could work across all our facilities and Fiix seemed to fit all our requirements. Training staff was easy primarily due to the inline videos on each screen. I gave a class with a brief overview; we then watched the support videos followed by a Q&A session. It worked very well. The guys then went away and spent a few days experimenting with the new CMMS on their iPads.”

Related Case Studies.