Download PDF

Takeaway Takeover: Adidas GLITCH's Innovative Experiential Marketing Strategy

Technology Category

- Application Infrastructure & Middleware - Event-Driven Application

- Sensors - Autonomous Driving Sensors

Applicable Industries

- Apparel

- Packaging

Applicable Functions

- Sales & Marketing

The Challenge

Adidas GLITCH was set to launch their new football boot range, the 'Prep Pack', and needed a marketing campaign that would not only match the brand's reputation for innovation but also drive app downloads and increase brand visibility in London. The target audience for this campaign was 14-19-year-old football playing Londoners. The challenge was to create a campaign that would resonate with this demographic, encouraging them to engage with the brand and its new product. The 'Prep Pack' was inspired by hard work and the brand wanted to associate this with the reward of play after long hours on the pitch. The challenge was to find a unique and innovative way to take GLITCH off the pitch and into a space that this core audience would associate with a post-match reward.

About The Customer

The customer in this case study is Adidas GLITCH, a sub-brand of Adidas that is known for its innovative and disruptive approach to marketing. Adidas GLITCH targets a younger demographic, specifically 14-19-year-old football players in London. The brand is known for its football boot range and is recognized for its innovative designs and marketing strategies. For the launch of their new 'Prep Pack', Adidas GLITCH wanted a campaign that would not only match their reputation for innovation but also drive app downloads and increase brand visibility in London.

The Solution

Adidas GLITCH decided to take over a fast food restaurant in East London, a place their target audience would associate with a post-match reward. The eatery was entirely rebranded as GLITCH, with every touchpoint reflecting the brand and its new product. The takeover included GLITCH product displays, exclusive apparel, and even a secret performance from North London's own drill rapper, Headie One. To generate buzz around the event, a teaser campaign was launched on social media. An abstract film was shared across the Instagram stories of adidas London, Premier League club players, and Headie One's channels, intentionally contrasting with the usual content seen by the target audience. This campaign drove app downloads and event registrations. On the day of the event, the GLITCH community was challenged to race to the shop to win a free pair of boots. The event was wrapped up with a film that brought together the product story, the GLITCH community, and the brand's irreverent expression.

Operational Impact

Quantitative Benefit

Related Case Studies.

Case Study

Fire Alarm System and Remote Monitoring Sytem

Fire alarm systems are essential in providing an early warning in the event of fire. They help to save lives and protect property whilst also fulfilling the needs of insurance companies and government departments.Fire alarm systems typically consist of several inter-linked components, such as smoke detectors, heat detector, carbon monoxide, manual call points, sounders, alarm and buzzer. The fire alarm system should give immediate information in order to prevent the fire spread and protect live and property.To get maximum protection a shoe manufacturer in Indonesia opted for a new fire alarm system to monitor 13 production sites spread over 160 hectars. Although the company had an existing fire alarm system, it could not be monitored remotely.It was essential that the new system would be able to be monitored from a central control room. It needed to be able to connect to the existing smoke detector and manual call point. Information should be easily collected and passed on to the Supervisory Control and Data Acquisition (SCADA) system. Furthermore, the system should have several features such as alarm management, auto reporting, being connected to many client computers without additional cost, and run 24/7 without fails. The company also needed a system which could be implemented without changing the architecture of the existing fire alarm system.

Case Study

IoT Applications and Upgrades in Textile Plant

At any given time, the textile company’s manufacturing facility has up to 2,000 textile carts in use. These carts are pushed from room to room, carrying materials or semi-finished products. Previously, a paper with a hand-written description was attached to each cart. This traditional method of processing made product tracking extremely difficult. Additionally, making sure that every cart of materials or semi-finished products went to its correct processing work station was also a problem. Therefore, the company desired an intelligent solution for tracking assets at their factories. They also wanted a solution that would help them collect process data so they could improve their manufacturing efficiency.

Case Study

IoT Data Analytics Case Study - Packaging Films Manufacturer

The company manufactures packaging films on made to order or configure to order basis. Every order has a different set of requirements from the product characteristics perspective and hence requires machine’s settings to be adjusted accordingly. If the film quality does not meet the required standards, the degraded quality impacts customer delivery causes customer dissatisfaction and results in lower margins. The biggest challenge was to identify the real root cause and devise a remedy for that.

Case Study

Zenon the Ideal Basis for An Ergonomic HMI

KHS develops and produces machines and equipment for filling and packaging in the drinks industry. Because drinks manufacturing, filling and packaging consist of a number of highly complex processes, the user-friendly and intuitive operation of equipment is increasingly gaining in significance. In order to design these processes as simple as possible for the user, KHS decided to introduce a uniform, transparent and standardized solution to the company. The HMI interface should meet the requirement for people with different qualifications and enable them to work on a standard platform.

Case Study

Retailer Uses RFID Scanner to Improve Efficiency

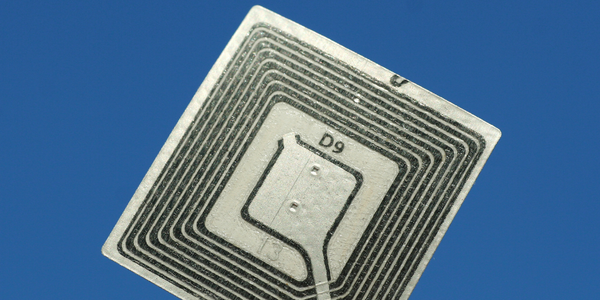

Patrizia Pepe wished to improve the logistics of their warehouse: accepting incoming goods from their production sites, movement of items throughout

the warehouse, and packaging of goods for distribution to the retail locations. They initially tried to use barcodes for this function. Because barcodes must be individually scanned within a line-of-sight, the acceptance of goods coming into the warehouse was too time consuming. Working with the University of Florence, Patrizia Pepe instituted a five-month pilot project beginning in August of 2009 to test the validity of an RFID solution. The pilot involved tagging of about 60,000 items for the second seasonal collection, and convinced the company to move forward with tagging all items.

Case Study

Monitoring and Controlling Automatic Mixing and Dispensing Machines

As technology advances, textile manufacturing has been transformed from a labor-intensive to a partially or fully automated industry. Automation is significant in all segments of textile production - from spinning to printing, and textile machinery manufacturers are constantly searching for new technologies and automation processes will increase the productivity of their machines. The color paste mixing and dispensing machine is an essential part of the printing and dyeing process. With the advantage of automatically computerized controls and database management, the system can significantly improve its dispensing precision, working efficiency and production quality as well as reducing material consumption.