Case Studies.

Our Case Study database tracks 18,927 case studies in the global enterprise technology ecosystem.

Filters allow you to explore case studies quickly and efficiently.

-

(5)

- (5)

-

(4)

- (4)

-

(4)

- (4)

- (2)

- (1)

- (1)

- (3)

- (2)

- (1)

- (2)

- (2)

- (1)

- (6)

Selected Filters

6 case studies

|

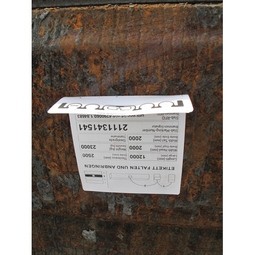

Automated Slab Tracking at ThyssenKrupp

S+P Samson

Steel slabs usually weigh between 20 to 40 tons each. After production, the surface is scaly and rusty. Outdoor storage and sea shipment expose the slabs to rough conditions. Loading ocean vessels is time consuming and total cost can easily exceed a few hundred thousand USD.RFID technology offers many benefits. RFID transponders are small, store the identity of the labelled product and enable readingout this data via antennas from a distance of several metres. However, there are special requirements for the use of RFID in thesteel sector. Firstly, the radio waves of the RFID readers are reflected by metal which creates major problems for reading out.And secondly, they must be attached securely as the heavy slabs weigh tons and can rub against each other during the transporton ships and trains, causing the labels to become detached or to be destroyed.

|

|

Multifunctional labels in Steel Service Centers

S+P Samson

Until 2007, the Kerschgens Group handled the processes that involve moving goods into and out of stock like many companies in the industry. The daily work of the logistics personnel was characterised by delivery lists and slips of paper. However, the market is changing, and so are the requirements. Whereas the company used to sell mainly standard products, the need arose to put together orders made up from many different individual parts. And working with lots of bits of paper frequently led to time being spent on searching and errors with goods movements. A new concept had to be developed to optimise the process

|

|

Reliable Identification Solutions for the Automotive Industry

S+P Samson

High quality standards and full material traceability are essentialrequirements for identification solutions in the automotiveindustry. Parts identification and container management areconsidered to be important factors for a problem-free productionprocess. The labels must also retain their adhesive properties on many different types of surfaces - from porous structures to oilymaterials. The labels should also be able to withstand rugged, high-temperature environments without tearing or peeling off.

|

|

Fully Automated Identification for Alping Italia

S+P Samson

Full material traceability ensures process reliability in production and it is a major building block for the economic success of manufacturing companies. To optimise production management, automated identification systems with tags which have barcodes printed on them are now increasingly used in production facilities and warehouses. This ensures full control from the receipt of raw materials to the finishing of the products and shipping.The steel industry in particular, is a difficult environment and the labels and tags that ensure full material traceability have to withstand extreme conditions. Raw materials and products have rough surfaces. In addition, the data carriers are exposed to enormous heat and heavy soiling. And last but not least, the whole identification process always has to be carried out under time pressure.

|

|

New GHS Regulations Require New Identification Concepts

S+P Samson

With the GHS regulations (GHS - Globally Harmonized System) the United Nations wanted to minimise the risks to human health and the environment arising from production, transport and the use of hazardous substances. Standardised danger symbols and texts now have to be used for the identification of chemicals around the world. 1200 quality products not only need to be produced, they also need to be stored and shipped in a professional manner. In April 2014, a dedicated team was set up to manage the changeover to the new GHS regulations under the umbrella of the PETROFER CHEMIE ICT (Information & Communication Technology) department. It was chaired by Roland Günther and Jonas Hartmann. They subjected the existing logistics and identification processes to some rigorous tests. They analysed and conceptualised.

|

|

Tray Identification at the Kennametal Drill Plant

S+P Samson

Kennametal's high quality drill bits along with their associated aluminium trays where they are arranged go through a thorough cleaning process involving ultrasound, damp and vacuum cleaning processes after machining is performed. Before entering this washing facility, the order documents and the tray are separated and then re-allocated after cleaning. A work step that involves a risk as analyses have shown that, on occasion, trays and order documents were allocated incorrectly after cleaning. Drills went through coating processes that were supposed to be used for a different order. Hence, there was a need to eliminate mix-ups altogether.

|