Case Studies.

Our Case Study database tracks 18,927 case studies in the global enterprise technology ecosystem.

Filters allow you to explore case studies quickly and efficiently.

-

(5,794)

- (2,602)

- (1,765)

- (764)

- View all

-

(5,073)

- (2,519)

- (1,260)

- (761)

- View all

-

(4,407)

- (1,774)

- (1,292)

- (480)

- View all

-

(4,158)

- (2,048)

- (1,256)

- (927)

- View all

-

(2,488)

- (1,262)

- (472)

- (342)

- View all

- View all 15 Technologies

- (1,732)

- (1,626)

- (1,605)

- (1,461)

- (1,423)

- View all 42 Industries

- (5,782)

- (4,114)

- (3,091)

- (2,780)

- (2,671)

- View all 13 Functional Areas

- (2,568)

- (2,482)

- (1,866)

- (1,561)

- (1,537)

- View all 127 Use Cases

- (10,333)

- (3,499)

- (3,392)

- (2,982)

- (2,593)

- View all 9 Services

- (503)

- (432)

- (382)

- (301)

- (246)

- View all 737 Suppliers

Selected Filters

18,927 case studies

|

Smart SCADA-based Deployable Communications & Information System

Adroit Technologies

Following the Fukushima incident in Japan, EDF-Energy NGL undertook a rigorous assessment into the resilience of its fleet of UK nuclear power stations against the highly unlikely occurrence of an extreme weather or other natural event. Through this process, they identified a requirement for the provision of mobile emergency response systems which will be deployed on the occurrence of such an event.

|

|

Metlac Case Study

VMware (DELL)

• Greater agility, flexibility and control • Cost reduction and process innovation • Improved user experience on a range of workstations and devices

|

|

Predictive Maintenance Software for Gas and Oil Extraction Equipment

MathWorks

If a truck at an active site has a pump failure, Baker Hughes must immediately replace the truck to ensure continuous operation. Sending spare trucks to each site costs the company tens of millions of dollars in revenue that those trucks could generate if they were in active use at another site. The inability to accurately predict when valves and pumps will require maintenance underpins other costs. Too-frequent maintenance wastes effort and results in parts being replaced when they are still usable, while too-infrequent maintenance risks damaging pumps beyond repair.

|

|

IIC - Intelligent Urban Water Supply Testbed

Water, after air, is the second most critical natural resource our lives depend upon. Maintaining adequate clean and safe water supply to urban residents has become ever-challenging. This is especially so under the pressure from the rapid urbanization of the populations in developing countries and increasingly severe constraints of available water resources in many parts of the world. The situation is exacerbated by the inadequate and aging equipment deployed in the water supply infrastructure and the ineffectiveness in the management of the operations of the equipment. The consequence of these conditions impacts to the health and quality of lives of millions of urban residents. The prevailing conditions in the urban water supply systems include: • Safety: Inability to timely detect water quality issues that may lead to health problems • Service Availability: Inability to detect, address and prevent, on a timely basis, operational issues that cause unnecessary service outages • Efficiency: Inability to assess and identify water leakages, and to identify and address energy over-consumption in heavy operational assets (e.g. water-pressurizing bumps), both leading to wastefulness of valuable resources and in the latter case negatively impacting the environment • Effectiveness: Inability to optimize the operation of a group of water-pressuring pumps to provide equitable water supply and to avoid equipment damages under these conditions.

|

|

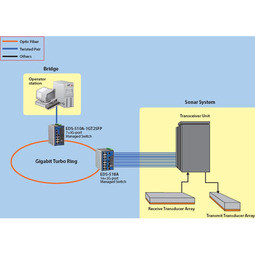

Real-time Networked Sonar System for Ships

MOXA

A multinational, knowledge-based corporation that delivers marine electronics solutions is utilizing industrial Ethernet technology to help ensure that operations at sea are dependable and optimal. Based in Europe, the company has nearly 4000 employees working in 20 countries around the world, and produces high-tech systems for offshore oil and gas operations, merchant marine systems, and various applications for the defense and aerospace industries. The company produces products and systems used by merchant vessels and offshore installations for positioning, navigation, automation, as well as for surveying and monitoring the seabed, and for fishing vessels and fi sheries research. As one of the major suppliers of high quality marine electronics in the world, their products include chart plotters for yachts, triple redundant dynamic positioning systems for oil drilling rigs, and sonar and instrument systems for scientifi c research vessels. Products used for marine applications must be rugged enough to endure the corrosive effects of salt water, and be able to withstand excessive amounts of vibration and shock. For this reason, the company only uses DNV and GL certified products and components to ensure that their systems can meet the high standards required by the maritime industry.

|

|

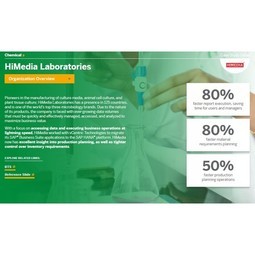

Embracing Business Success in Real Time

SAP

· Increase control over growing Big Data to improve business decisions · Manage data for 28,000 biotechnology stockkeeping units in the fields of microbiology, molecular biology, animal cell cultures, plant tissue cultures, and lab ware for laboratory chemicals · Accelerate report generation and analysis with real-time data

|

|

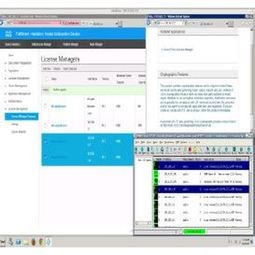

Testing Cisco Hosted Collaboration Solutions

Gambit Communications

Cisco provides many applications as a part of this solution; Hosted Collaboration Fulfillment-Mediation (HCM-F), Cisco Prime Collaboration Assurance, Cisco Unified Call Manage(CUCM), Cisco Unified Presence(CUP), Cisco Unity Connection(CUCxN), Cisco Unified Operation Manager (CUOM), and Cisco Prime License Manager. There are many communications technologies linking the different components: SOAP, REST, XML, SNMP, Cisco IOS, LDAP, VOIP, Telnet and SSH. They all need to be verified for various combinations of scenarios, features and scalability. That is a huge task which would need many different tools to be used and configured. Instead Cisco decided to use one tool that can provide all the test environments they need, MIMIC Web and SNMP Simulator.

|

|

Make Smart Manufacturing a Reality

Small changes in productivity equal large gains for the bottom line is true for fast-moving consumer goods and food service. However, traditional Statistical Process Control is now facing limits.

|

|

University Duisburg Launches NectOne for IoT Research

ThingWorx

In order for the IoT to become fully operationalized, system integration of devices and data with existing businesses systems and processes is vital. In reality, many manufacturing companies like NectOne® with individual systems often find it very difficult to build and use intelligent structures between their systems. Many of the data sources as well as connected systems may be external to the business. This systems integration work can be complex and difficult to manage, but is vital to achieving business objectives. The final goal is to deliver cloud base production control.

|

|

Enhancing Environmental Control and Reducing Emissions in Nordic Smart Cities

Libelium

Municipalities and public institutions are concerned about air, water, noise or lighting pollution in cities. In the last years, it has become mandatory through several international regulations to reduce emissions that could impact in the environment and also inhabitants lives.Being a Smart City is more than just a trend, is a commitment with society and stakeholders.Carbon Track and Trace Project (CTT) aim is reducing CO2 emissions, combating climate change in cities and also developing a decision support system for cities greenhouse gas (GHG) emissions monitoring. It was funded by the Low Carbon City Lab flagship of the EU Climate KIC programme.

|

|

Metering Technology Case Study

Lantronix

Quadlogic Controls is North America’s leading provider of Power Line Communications metering technology. The company’s digital electric Advanced Intelligent Smart Submetering Systems are in use in high-rise office, residential, commercial, and industrial facilities across the U.S. and Canada. In the face of rising energy costs, deregulated markets and complex energy pricing, the data provided by Quadlogic’s metering systems is critical to an organization’s energy management decisions. Quadlogic’s patented Power Line Communications technology utilizes a building’s existing power lines to transmit metered data, so no additional wiring or meter readers are required. When the system was first developed more than 25 years ago, it used a serial device via a telephone modem to enable communications with the outside world. As technology advanced and customer preference shifted from telephone service to Internet, the ability to offer network-enabled metering technology became an imperative if Quadlogic was to remain competitive. The decision was made to integrate the capability into its next-generation Power Line Communications system.

|

|

Solid Enterprise Planning, Scheduling, and Compliance Management

Ash Grove Cement would like to find a solution in automate maintenance data collection at each facility for a well-defined enterprise asset management process to support equipment performance reliability.

|

|

VMI Group

WIBU-SYSTEMS

With field engineers servicing sophisticated tire production machines around the globe, tire machine specialist VMI felt the need to secure access to the Programmed Logic Controllers on installations. This leading Dutch tire machine manufacturer realized that a centrally administered password key protection scheme would safeguard intellectual capital and machine investments for the future.

|

|

Transforming insurance pricing while improving driver safety

The Internet of Things (IoT) is revolutionizing the car insurance industry on a scale not seen since the introduction of the car itself. For decades, premiums have been calculated using proxy-based risk assessment models and historical data. Today, a growing number of innovative companies such as Quebec-based Industrielle Alliance are moving to usage-based insurance (UBI) models, driven by the advancement of telematics technologies and smart tracking devices.

|

|

MAAC Machinery Saves 50% of Support Cost Using Remote Access

HMS Networks

MAAC is a corporate situated in Chicago and specialized in manufacturing thermoforming machinery and other companion products. MAAC found out that the automation control technology was the key to succeed in the machinery sector.

|

|

Coal Dust Suppression System

Opti

One of the country's largest coal transfer facilities operated by a large multinational, required an intelligent rainwater harvesting system to reduce potable water use and help eliminate stormwater discharges.

|

|

Digital Transformation of Atlanta Grout & Tile: An IoT Case Study

SynLogics

Atlanta Grout & Tile, a Tile, Stone & Grout restoration company based in Woodstock, Georgia, was facing challenges with its traditional business model. Despite steady growth over the years, the company was falling behind the web revolution and missing out on the opportunity to tap into a new consumer base. They were using independent software from different vendors for each of their department information and workforce management. This resulted in a lot of manual work on excel and the need to export/import data between different systems. This not only increased overhead costs but also slowed down their response to clients. The company also had to prepare numerous reports manually and lacked access to customer trends for effective business decision-making.

|

|

Improving Recycling Collection Performance

Enevo

In 2015, HFTH, members of the Western New York Coalition for Donated Goods (WNYCDG) and the City of Buffalo diverted 4,800 tons of unwanted clothing and textiles for reuse. In an age of growing consumerism, HFTH’s ambition is to provide even greater support for the homeless. Its management team’s aim is to expand their recycling and collection capabilities, with the goal of achieving zero waste to landfill from its operation. HFTH was founded in 1990, starting out with a small number of recycling collection containers around the WNY area. Nick Calandra, COO and Corporate Secretary of HFTH, describes the management of those containers saying, “We personally checked every container and it was easy to memorize locations and estimate fill speeds in order to organize our truck routes and collections.” However, as the organization grew and the collection points spread across a wider area, manual logistics planning became more complex and efficiency dropped. It got to the point where containers were being emptied when only 30% full, simply because they were located on the regular collection routes. HFTH sought a solution that would allow them to scale operations, optimize collections and, wherever possible, automatically adjust routes to maximize collection efficiency.

|

|

Cisco openBerlin IoE Center

relayr

Cisco IoE innovation Centers around the world enable and showcase local innovation and development. relayr had the unique opportunity to be involved in building the connected openBerlin infrastructure from the very beginning. In a building that was conceived from the outset to be completely monitored and controlled by smart systems, relayr set up the middle layer of connectivity – joining all of the separate legacy systems to allow meaningful cross-platform communication.

|

|

Digital Twin in Chemical Plant Construction

AVEVA

Evonik was planning to construct a new methionine-6 plant and was looking at ways to more efficiently go through this process and make sure it's integrated with their existing online data management infrastructure.

|

|

GE Detects Early Defects and Improves Capacitor Production

FogHorn

Hard to Detect Capacitor Failure Conditions Reducing Yield, Increasing ScrapGE was facing multi-million-dollar scrap problems due to limited real-time insights into the entire production process. They believed they could significantly improve the yield and reduce the scrap of their manufacturing operation by analyzing a large amount of RFID sensor data being produced by 30+ machines during the production cycle. This included correlating processing data in real-time from several sources to create an edge intelligence layer with FogHorn for real-time condition monitoring throughout the production process. The goal was to identify defects early, quickly determine the root cause, and speed remediation actions to improve yield and reduce scrap costs.

|

|

Empowers Mevia to Improve Medical Adherence and Deliver Real-Time Feedback

Aeris

Mevia provides intelligent solutions to improve the quality of medical treatments. Mevia develops solutions that enable people to take the right medication at the right time. This helps improve adherence, which is one of the greatest obstacles to successful medical treatments. According to statistics from the IMS Health Institute poor adherence costs over $500bn globally in avoidable healthcare costs and the World Health Organisation said that, “improving adherence would have a greater impact on health than any potential discovery in medicine.” Mevia has created technology, which can be adapted to work in blister packs, pill dispensers, and pill pouches, providing patient support and personal adherence feedback in real-time. Missed medication and adherence is a huge challenge globally for healthcare providers and pharmaceutical companies alike. Up to $289bn is spent on missed medication and adherence issues in the US, and the global pharmaceutical market’s revenue loss is estimated to be $564 billion due to medication non adherence. Being an innovative, yet growing company, Mevia needed to partner with an expert in IoT. However, this partner needed to offer competitive pricing, global coverage, and the agility to adapt their services as Mevia grows. Many providers had high fixed costs which would prove to be a deal breaker for Mevia.

|

|

IIC Connected Care Testbed

Infosys

With extended life spans of the world's population comes an increased burden on the world's health care systems. Up to 80% of older adults have at least one chronic health condition that requires continual treatment management. With the advent of accessible IoT technologies, health care providers are now able to access patient remote monitoring and health informatics that can make management of these populations more cost effective and increase the quality of care. However the slow pace of technology adaptation and proprietary solutions among medical device manufacturers makes it difficult for caregivers to implement a cost-effective IoT solution for patients which can bring together all pipelined stages of patients' treatment, from initial diagnosis through lifetime disease management. GOAL To develop an open IoT ecosystem for clinical and remote medical devices that can bring together patient monitoring data into a single data management and analytics platform.

|

|

Beer Distributor Improves Security, Shipping Capacity, and Service

Cisco

Enjoy a beer on the upper Texas Gulf Coast, and you can probably thank Del Papa Distributing Company. Founded more than a century ago, the company today distributes 10 million cases of beer annually, from 30 suppliers. More than 375 employees work at headquarters in Texas City and two other distribution centers. The family-owned company has a simple aim: to be a great beer distribution company. So when Del Papa set out to build a new 27-acre headquarters, company leaders thought about how technology could contribute to its greatness. “We wanted the new distribution center to have a single, secure network we could use for physical security, communications, collaboration, and even monitoring the temperature of our inventory,” says Steve Holtsclaw, Manager of Information Systems for Del Papa. The old building, in contrast, had separate networks for voice, data, video, and physical security. Separate networks were expensive and got in the way of business. For example, personnel could only monitor video surveillance cameras from certain workstations. And Wi-Fi performance in the warehouse area wasn’t reliable enough for the voice-activated order-picking system.

|

|

Pima County takes significant steps in preserving water source

AVEVA

Pima County is facing the following challenges: - Management of more than 60 million gallons of sewage each day to support the region’s population of more than 1 million people. - To take immediate action when alarms sound alerting operators to issues within the plant The solution should be able to enable the following feature: - To ensure capture of institutional knowledge of current workforce for effective training of future operators - To employ an effective Situational Awareness strategy enabling personnel to effectively understand and address operations of the facility - With assets spread out over more than 700 miles, operational management is difficult

|

|

NRG Achieves Optimal Balance Between Asset Life and Performance

NRG power plants across the US provide about 48,000 megawatts of generation capacity, enough to power more than 38 million average households. NRG also provides retail electric service for nearly 3 million retail customers across the US. As the nation’s leading integrated power company, NRG is always working to improve operating efficiency in its power production, balancing the maintenance requirements of its GE units among the NRG fleet with a need to maximize power output to meet the needs of the bulk power markets.

|

|

Increase in Laundry Facility Output with Item Intelligence

Impinj

Established in 1854, Berendsen is a European textile service business with 127 locations in 15 countries throughout Europe. Berendsen provides service solutions to lease, source, clean and maintain textiles used in various settings, including healthcare, washroom, hotel, restaurant, and cleanroom. Since 1996, Berendsen has focused on providing services for the healthcare and industrial areas, becoming a leader in their field. Supplying hospitals, retirement homes and care facilities with linens represents a significant part of the daily business for one Berendsen facility in Germany. This facility receives tons of used linens each day. The contaminated linens, shipped in laundry bags and roll cages, are weighed rather than counted to protect workers from the risk of infection. Once the linens are washed, they are manually sorted, giving Berendsen insight into what they’ve received and how much manpower they will need to process the laundry. Berendsen needed a solution that allowed for the bulk reading of contaminated linens, enabling them to better plan the manpower needed to finish each job. They also wanted a solution that would scale in the future to meet other project needs. In the past, RAIN RFID solutions had been implemented in other Berendsen facilities to give better insights into laundry care. As bulk reading was the number one priority of the new system, a RAIN RFID solution, powered by Impinj technology, was implemented to analyze the bulk shipments arriving at the facility.

|

|

AUTOSAR-based Battery Management System

Lemberg Solutions

We aimed to build an advanced BMS with improved accuracy of SoC and SoH algorithms for hybrid electric and electric vehicles. Our demo was built using automotive grade components and designed to conform to ASIL-D certification. The scope of work covered such safety features as Over/Under Voltage, Over/Under Temperature Protection, Short Circuit Detection, Cell Balancing, CAN Communication, and Faults Handling. Read the full case

|

|

Metal Fabrication

ABB

As each mast section needs a total of 222 reliable welds, manufacturing them is an extremely labor intensive process.Until recently, STROS had to use highly skilled welders to make these sections. Although it has been using robots for 25 years, these machines could not manage the complex arc welds in narrow spaces needed for these particular components. Consequently, in order to produce a satisfactory number of mast sections it had to employ three welders per shift at three separate workstations to make these pieces. Apart from the obvious outlay this required in terms of manpower and space, STROS found it increasingly difficult to recruit the highly qualified welders needed for this work. That's why in 2007 the company decided to hold a tender for the complete robotization of its manufacturing process for mast sections. Of the four firms who participated, only the ABB group could fulfill all its requirements.

|

|

Consorcio Energético Punta Cana Macao (CEPM)

Ingenu

The Dominican Republic has had its share of challenges as efforts to deliver power more efficiently to consumers have increased. Sub-standard service, inadequate capacity and frequent black-outs have been a common occurrence in this emerging island country. However, as the government energy industry was deregulated, the Dominican Republic looked to companies such as CEPM to deliver innovative energy solutions to its citizens. As such, CEPM sought to find a reliable advanced metering infrastructure (AMI) solution which would withstand rigorous power fluctuations and provide remote monitoring and management of its electrical grid. Additionally, the company was launching a pre-paid electricity program which required reliable data transmission and two-way communication capabilities. Coverage was also an issue due to the country’s varied topography.

|