Case Studies.

Our Case Study database tracks 18,926 case studies in the global enterprise technology ecosystem.

Filters allow you to explore case studies quickly and efficiently.

-

(5,794)

- (2,602)

- (1,765)

- (764)

- View all

-

(5,073)

- (2,519)

- (1,260)

- (761)

- View all

-

(4,407)

- (1,774)

- (1,292)

- (480)

- View all

-

(4,157)

- (2,048)

- (1,256)

- (926)

- View all

-

(2,488)

- (1,262)

- (472)

- (342)

- View all

- View all 15 Technologies

- (1,732)

- (1,626)

- (1,605)

- (1,460)

- (1,423)

- View all 42 Industries

- (5,781)

- (4,113)

- (3,091)

- (2,780)

- (2,671)

- View all 13 Functional Areas

- (2,568)

- (2,482)

- (1,866)

- (1,561)

- (1,537)

- View all 127 Use Cases

- (10,333)

- (3,499)

- (3,391)

- (2,981)

- (2,593)

- View all 9 Services

- (503)

- (432)

- (382)

- (301)

- (246)

- View all 737 Suppliers

Selected Filters

18,926 case studies

|

Detecting and Reducing Cost of Fraud Rings

A leading insurer wanted to reduce its multi-billion dollar expenditures on auto insurance claims, which is its largest annual expense. Currently, the company avoids paying out only about 0.33% of the predicted 10% of fraudulent claims. The insurer uses both manual (60-65%) and automated systems (30-35%) to flag questionable claims. These claims are passed on to the investigative case managers who read adjuster and other member notes, explore the fraud watch list, and search the web. Their existing approach cannot easily discover fraud rings or, more importantly, collusion among other fraud rings. Moreover, the investigative team typically decides in 30 days or less on whether to pay or deny a claim. This is due to heavy caseloads and expectations for a quick turnaround in claim processing in order to keep customers satisfied.

|

|

Smart Manufacturing for Better Competitiveness

AIWA was having challenges in monitoring and optimizing energy efficiency of an entire set of different machines managed by Smart Factory Advisor, balancing of machine work loads of the productive capacity of each processing machine in the production, and collecting data to optimize electricity purchases polices for the forthcoming energy liberalization.

|

|

Imperial Vending IoT Solution

USA Technologies

Imperial Vending has earned a reputation for outstanding service and quality and is always on the lookout for new ways to enhance this brand image. The company has used technology to improve service excellence since entering the vending business in the early 90’s. Handheld route systems, for instance, have helped Imperial Vending closely monitor customer consumption profiles and maintain transparent and accurate reporting for customer commissions. Another key reason to move to wireless technology was to improve operational efficiency. Imperial Vending had already attempted another solution for advance assembly of delivery orders, a technique known in the industry as pre-kitting. However, Imperial Vending found that their pre-kits were often significantly inaccurate because of unpredictable variations in account sales. While this early test of pre-kitting helped get drivers on their way from the warehouse more quickly, it did little to help with route efficiency and keeping fresh products in customer vending machines.

|

|

Smart Transportation at Boyaca using Carriots

The fulfillment of time schedules in each node is a key element of the Quality of Service and late delivery results in significant extra costs (second deliveries). Boyacá did not know the real time at which deliveries took place, they just had what was reported by the receiver and the carrier, and both were not necessarily coincident. To receive and handle this inaccurate information, they had in addition to make phone calls. When deliveries were done out of time, the company had no control over the point at which the delay had taken place and therefore could not manage to improve accuracy. In addition, the clients were unsatisfied and complained as they also lost sales due to late deliveries. The company needed to have direct real-time information of arrival and departure times at each one of the hubs of the distribution chain to control costs with the lowest possible investment in spite of the large number of vehicles involved (several hundred).

|

|

CSL Faster and Stronger

ZTE

In order to keep a leading position in the new Internet era, CSL makes a strategic decision to upgrade the whole network, for guaranteeing the development of high-speed data service.

|

|

Comac Srl: The process is running

EPLAN

Filling bottles and kegs with beverages necessitates sophisticated, highly automated machines in a variety of sizes to cater for microbreweries and major producers. Comac wanted to integrate electrical and fluid power engineering with a lasting effect on development of machinery.

|

|

Wireless Nodes And Gateways to Power Research Platform on the IoT

HiKoB

Supported by the French National Research Agency (ANR) in the framework of the program for investments in the future, INRIA (the leading French research institute on ICT) drives the construction and installation of a research platform dedicated to the scientific community to test, simulate and develop around the future of Internet of Things (FIT). The FIT platform is composed of various subsystems among which a large-scale platform of smart objects: FIT IoT-LAB, managed by INRIA.

|

|

Bekaert's Journey to Manufacturing Digitalization with TCS

Tata Consultancy Services

Bekaert, a major player in the steel wire industry, was facing significant challenges in its manufacturing operations due to outdated data platforms. The company was unable to trace genealogy beyond a week's data and lacked diagnostic analysis of plant operations, which severely hampered decision-making. The absence of automation in benchmarking operations and extensive reporting on plant management further complicated the situation. To enhance efficiency and effectiveness in multiple focus areas, Bekaert needed a modern data platform capable of managing large volumes of data and generating actionable insights. The company aimed to drive quality, overall equipment effectiveness (OEE), and plant productivity based on these insights.

|

|

Delivering Technical and Financial Value to Cloud Consumption: A Strategic Blue and NTT DATA Partnership

NTT Data

Strategic Blue, a cloud financial services company, was facing a challenge in helping its customers understand and optimize their cloud services consumption. With the rapid growth of the hyperscale market and the continuous introduction of new products and enhanced features, cloud buyers found it increasingly difficult to understand the most appropriate services for their business. This was especially challenging as they now required specialized skills to maintain and manage the systems and also to understand the best ways to financially optimize the services being consumed. Strategic Blue, while having a strong understanding of the financial aspects of cloud consumption, needed a partner that could provide technical expertise at scale.

|

|

Major Services Provider Cuts the Price of Success

Dell Technologies

To support continued growth, Cofely wanted to move to a scale-out storage solution that streamlined costs and avoided expensive forklift upgrades.

|

|

Underpins Expansion of UK Fire & Security System Leader

Vodafone

CSL invented integrated dual signalling back in 1996 and pioneered the move from wired to wireless technology in the electronic security industry. Today, its solutions protect over 350,000 premises throughout Europe. Working with Vodafone IoT the company is using its pedigree gained in the Fire & Security sector to move into new verticals where robust critical connectivity adds value to M2M/IoT applications.

|

|

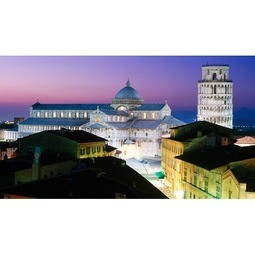

The Real Smart Mobility

Pisa, one of Italy’s most visited by tourists in Italy, is the major airport hub in Tuscany and one of Italy’s centers of excellence in science and technology with three universities and many technology businesses. With more than 200.000 habitants in the urban area and over 300.000 monthly tourists, Pisa’s historic city centre was facing a dramatic increase in congestion. Due to the structure of the city increasing congestion impacted not only the immediate city center, but also major ingress and egress points. With the goal of reducing traffic to sustainable levels without harming the local economy, Pisa decided to introduce a congestion fee for the city center and major traffic roads. Due to the various different necessities of a highly tourist focussed infrastructure, the system for the congestion zone had to be highly variable in configuration covering not only the regulation of basic ingress and egress traffic, but allowing to regulate even time for certain categories of traffic (tourist busses, city logistics, habitants,…). As Pisa aimed for a digitalization of services, all fees should be payable over the internet as well as offline at the various helpdesks of PisaMo, the local public mobility company.

|

|

Driving Global Innovations with End-to-end SAP Solutions and Services

SAP

For more than 25 years, itelligence has helped more than 5000 customers get the most from their SAP applications. Now a global business IT services provider in the NTT Data Group, itelligence is the only SAP partner with six certifications, including SAP Platinum Partner. It has locations in 23 countries and has been named SAP North American Partner of the Year for 9 straight years. In 2016, SAP honored itelligence with two of its prestigious Pinnacle Awards: SAP S/4HANA Adoption Partner of the Year and Global Value-Added Reseller. As more of its customers migrate to SAP HANA for advanced data processing and analytics, itelligence is helping them make the transition as seamless as possible.

|

|

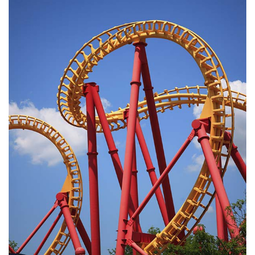

IIoT Solution for an Improved Customer Experience

Advantech B+B SmartWorx

A theme park was always looking for ways to enhance the customer experience, and minimizing wait times at attractions and foodservice outlets was one of the key concerns. Tracking and analyzing visitor behavior could potentially let management address it. The first step would be to have the analytics software look at things like advanced ticket sales, weather forecasts and previous attendance records to help management make staffing decisions several days in advance. Collecting and analyzing data could also improve day to day operations. If equipped with the right kinds of information, the control center could make informed decisions about where to place staffing resources. If the line at a water ride was getting too long, management could add staff and launch more boats. If the line at a foodservice station was getting too long, management could send costumed characters to hand out menus and entertain the guests, thus making the wait less painful. To track where visitors were and what they were doing, park management would need to gather data from devices like surveillance cameras, foodservice cash registers, and ticketing machines. But the plan would also require placing some of these devices in locations where trenching and installing new cable connections would be both disruptive and expensive.

|

|

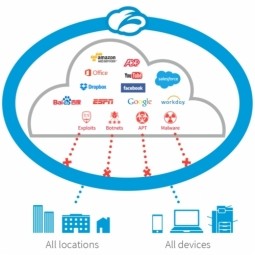

Global Automotive Components Manufacturer

Zscaler

With an increasingly mobile global workforce, ensuring security and applying uniform policy across all users and devices was a critical need. Historically, the company was using two on-premise solutions (Websense and a Squid Linux service) both of which were nearing the end of their contract periods. The company wanted to establish and enforce a global policy for internet access, provide secure access to the internet for all employees and ensure uniform coverage for the growing number of remote users, and mobile devices

|

|

Endeco Case Study

B-SCADA

Endeco needed a way to consolidate and visualize real time data from an aggregated demand site unit (DSU), an aggregation of site loads and generators which allows many sites to be combined in a virtual power plant through reduction of site loads or ramping up of generation.

|

|

The True Cost of Downtime for Manufacturers

NEC

The testing, checking and tracing of the component source is essential to produce quality products. Servicing customers when company representatives are in the field addressing possible failures. Maximum uptime. Progressive Stamping, Inc. wanted a solution that can meet all these requirements.

|

|

Smart Cities Control the Health of Cultural and Historical Monuments

Telefonica

The customer wants to control of the “health status” of cultural and historical monument of the city in order to facilitate decisions on maintenance and preservation.

|

|

Centralizing Data for Improved Efficiency: A Case Study on Malvern Panalytical

Aras Corp

Malvern Panalytical, a UK-based hi-tech electronics company, was grappling with the challenge of decentralized data storage. The company had a vast amount of unstructured data scattered across various platforms, from hard drives to emails and floppy disks. This made the data searching process extremely cumbersome and inefficient. The company's rapid growth, from 200 to over 1,000 employees in a decade, and expansion across three continents further exacerbated the need for a more structured and centralized data system. As a company involved in electronics manufacturing and software development, it was crucial for Malvern Panalytical to find a platform that could structure all their data, track all modifications of documents in real time, and provide clear visibility of the internal information flow across all its facilities.

|

|

Data management as a part of your cybersecurity strategy

AUVESY-MDT

Coordinating data in the age of digitalisation presents a real challenge, especially where production facilities are concerned. The task of maintaining the many and varied components used in production also entails working with a wide variety of different software packages (editors) Each change that is made to the software results in a new version that has to be securely stored – versions need to be properly managed and there can only ever be one version that is the latest authorised version. But how can you make sure that all changes that were made to the software now running on the machine/device were authorised?

|

|

Ensuring reliability and security of data feeds for Glanbia

Asavie

Core to Glanbia’s manufacturing operations is the need to guarantee the reliability and security of data feeds from its in-plant manufacturing execution systems (MES) to its field force.

|

|

Business Continuity and Energy Savings of Primary Data Centre

Johnson Controls

Ericsson required a new chiller solution to replace the three outdated Trane chillers that supplied the data centre’s cooling. For the new retrofit, the company needed a solution with tangible results, high reliability, as well as a centralized support and no downtime during the project.

|

|

Volkswagen V-Charge Collaboration: Driverless Valet Parking

RTI

In research programs, the compute intensity of any specific module cannot be determined ahead of time and is subject to continuous change; the ability of one compute engine to manage its load cannot be determined until runtime. The infrastructure needs to provide clear feedback when communication deadlines are not being met byconnected modules. This requires the ability to rapidly and easily reallocate modules to networked nodes. In other words, modules should be able to be reorganized around the distributed architecture without the time and effort of reconfiguring the underlying network integration. This way, researchers can stay focused on application level issues rather than dealing with system architecture problems created by changes in systems integration.

|

|

Serving Members, Increasing Competitiveness through Innovation and Rapid Time to Market

IBM

Blue Shield of California wants to better support members and boost competitiveness by accelerating the provisioning of new systems while improving IT agility to get new offerings to market fast.

|

|

Making Straddle Carriers Talk

HMS Networks

To enable the office to keep track of the straddle carriers' status, APM wanted to install a wireless system which would enable communication between the straddle carriers and the central office. The problem was that the carriers use a CAN-based bus internally which could not communicate with the Modbus-TCP-based monitoring system that was to send the data to the office.

|

|

deviceWISE Technology and m2mAir Cloud Enable Connectivity

ME-Automation Projects (Mitsubishi Electric)

Envision Solar believes the IoT offers great value because communicating with the components of the charging stations and the company's other products enables design improvements and preventative maintenance through IoT's data intelligence.

|

|

Utah Transit Authority Provides Secure Connectivity

Sierra Wireless

The Utah Transit Authority (UTA) provides public busing services across a 1,600-square mile service region serving 2 million residents' 80% of Utah's entire population. The organization wanted a secure, consistent mobile connectivity for its vehicles to support fare collection, mobile communications and other applications.

|

|

Digital Twin In Smart Factory

Faststream Technologies

Entitles multiplex products which to be designed, imitated, and validated for multi-physics simulation, electronic design automation, and Faststream’s software management – across various domains without the requirements of physical prototypes. Faststream creates Digital planning, simulation, and optimization of the production with automatic generation of the PLC code that generates the production digital twin. Faststream’s Digital Twin solutions are continuously fed with data from the physical product and the production amenities, which guides to the new perceptions. With the partnership of Mindsphere Faststream Technologies is Feeding back all intuitions into the complete value chain– right back to product design – generates a fully closed decision-making loop for the continuous optimization of the production and product in the real world. Technology stack:Manufacturing Execution SystemsMechatronics Concept DesignerTotally Integrated AutomationMindSphereIn Oil and Gas Company: The Client:One of the reputed consultants who took part in the designing, manufacturing of cutting-edge technology systems and products for the oil and gas industry.Profound competency across subsea, onshore/offshore, and surface projects. The Problem:The client looked for real-time visibility for the health status of the Early Production System.More signals were processed and human intervention was unable to find anomalies that lead to performance abasement.The yield and profitability of the projects decreased as there was a lack of sensor intelligence or apparatus detections.

|

|

Pay-per-Use for Digital Computed Radiography (CR)

WIBU-SYSTEMS

Agfa HealthCare’s Easy Payment Scheme for computed radiography offers a complete setup for digital imaging – including equipment and software – without upfront investment. Agfa needed a solution to protect its offer against fraudulent use.

|

|

Lean Manufacturing Process Flows

Decisyon

A multi-national manufacturing company was unable to coordinate the work of all departments involved in the production processes. The company lacked both real-time views into the systems and methods of communication. This situation meant small problems could cause big delays in filling orders, and customers would get frustrated. Additionally, the business’s manufacturing process flow was labor-intensive and error-prone with manual checks on information coming from various departments using Excel spreadsheets. Naturally, the process was slow and not conducive to process improvements, nor was unstructured data (emails, phone calls) shared or saved for future reference. The planning manager wanted a transparent way to find out whether the manufacturing process could fulfill the production plan sent from SAP. As part of his evaluation, he needed to be able to: - Identify potential problems before they happened - Collaborate with coworkers around critical data points - Analyze the historical data, so he could continue to improve the lean production process

|