Case Studies.

Our Case Study database tracks 8,303 case studies in the global enterprise technology ecosystem.

Filters allow you to explore case studies quickly and efficiently.

-

(3)

- (2)

- (1)

-

(2)

- (1)

- (1)

- (1)

- View all

-

(1)

- (1)

-

(1)

- (1)

- (4)

- (1)

- (1)

- (2)

- (2)

- (1)

- (1)

- (2)

- (1)

- (1)

- (1)

- (2)

- (1)

- (1)

- (1)

- (1)

- View all 5 Suppliers

Selected Filters

6 case studies

|

Robot Saves Money and Time for US Custom Molding Company

ABB

Injection Technology (Itech) is a custom molder for a variety of clients that require precision plastic parts for such products as electric meter covers, dental appliance cases and spools. With 95 employees operating 23 molding machines in a 30,000 square foot plant, Itech wanted to reduce man hours and increase efficiency.

|

|

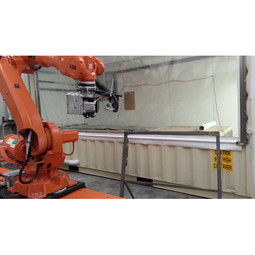

ABB Robot Calibration

RoboDK

The company manufactures marina products through robot milling but observed important errors in the surface quality of their machined parts. It uses an ABB IRB 6640-130/3.2 robot, which has 130 kg payload, 3.2 m reach, 0.050 mm repeatability, and was not factory calibrated. On top of that, the robot is placed on a linear track, which introduces yet another source of errors.

|

|

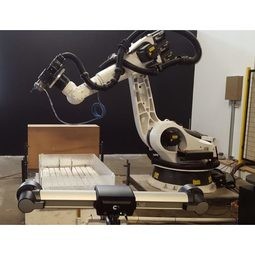

Accurate Robot Machining

RoboDK

Industrial robots are highly repeatable but not very accurate. However, through a robot calibration process the accuracy of a robot arm can be improved to the point where it is close to its repeatability, usually under the 0.100 mm mark. This is becoming very attractive to small and medium enterprises as robot arms are very affordable and can be used for multiple manufacturing applications, including machining materials such as wood, plastic or marble.

|

|

Robotics Case Study

Lantronix

Help GrassAds enhance the wireless communication between its painting robots and control systems for better quality performance in highly congested areas.

|

|

Grabit Case Study

Flextronic

Grabit, a promising startup, wanted to take its revolutionary electroadhesion gripping technology to market. Flex Lab IX partnered with Grabit to perform state-of-the-art testing and make business connections that would help the company fundamentally change factory and warehouse automation. Today's factories and warehouses need automation technologies that can handle fragile electronics such as flat-screen TVs and solar panels. Grabit invented a new technology that could revolutionize factory and warehouse automation. But this groundbreaking technology had to undergo rigorous testing before it could launch.

|

|

Remote operation of deployed teleoperated robots - Sarcos

Sirqul, Inc

Remote operation of deployed teleoperated robots (Guardian™ S) to perform complex tasks and video mapping and monitoring in areas where human safety is at risk.

|