Case Studies.

Our Case Study database tracks 8,303 case studies in the global enterprise technology ecosystem.

Filters allow you to explore case studies quickly and efficiently.

-

(2)

- (1)

- (1)

-

(1)

- (1)

-

(1)

- (1)

-

(1)

- (1)

-

(1)

- (1)

- View all 5 Technologies

- (2)

- (1)

- (1)

- (1)

- (1)

- (1)

- (1)

- (1)

- (1)

- View all 5 Functional Areas

- (1)

- (1)

- (1)

- (1)

- (1)

- View all 5 Use Cases

- (1)

- (1)

- (1)

- (1)

- (1)

- (1)

- View all 5 Suppliers

Selected Filters

5 case studies

|

Fully Automated Visual Inspection System

Beckhoff

Tofflon has developed a fully automatic machine that uses light to inspect vials, medicine bottles, or infusion containers for glass fragments, aluminum particles, rubber grains, hairs, fibers, or other contaminants. It also detects damaged containers with cracks or inclusions (microscopic imperfections), automatically removing faulty or contaminated products. In order to cover all production processes for freeze-dried pharmaceuticals, Tofflon needed to create an open, consistent, and module-based automation concept.

|

|

Preserving Security and Operator Safety

PTC

To improve customer satisfaction by minimizing downtime of automated optical inspection machines while preserving security and safety.

|

|

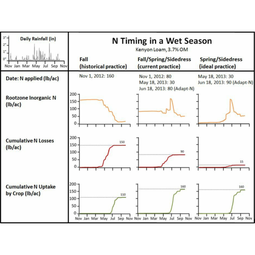

Diverse N Management Practices Generate Value to Farmers

Adapt-N

Shannon Gomes, owner of Cedar Basin Corp Consulting, has long been searching for a better way to monitor nitrogen (N) available and provide precise N recommendations. He has tried "all the different nitrogen management tools", with varying results, but has never been satisfied. He is looking for a real-time, location-specific adaptive N recommendation model that accounts for weather, management practices, and field variability.

|

|

Remotely Control, Monitor and Manage Lighting Systems

Mesh Systems

Intermatic needed a solution to help their customers drastically reduce costs associated with making sure all billboard lights were on and working properly. The traditional method was costly, time consuming and inefficient as may billboards are located in isolated regions.

|

|

8x increased productivity with VKS

VKS

Before VKS, a teacher would spend a lot of time showing a group of 22 students how to build a set of stairs within a semester of 120 hours. Along with not leaving the teacher much time to provide one-on-one support for each student to properly learn carpentry, it also left a considerable amount of room for error. Key information would be misinterpreted or lost as the class was taught in the typical show-and-tell way.

|