Case Studies.

Our Case Study database tracks 18,927 case studies in the global enterprise technology ecosystem.

Filters allow you to explore case studies quickly and efficiently.

-

(2)

- (2)

-

(2)

- (2)

-

(1)

- (1)

- (2)

- (2)

- (2)

- (2)

Selected Filters

2 case studies

|

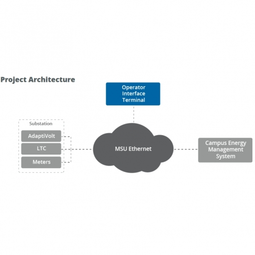

Saving Energy on Campus with Energy Optimization Technology

Utilidata

The Project Universities have long put forth great effort to improve overall energy efficiency for buildings and facilities on campus. To improve electrical energy efficiency, universities have used more economical lighting systems, high efficiency motors, building management systems, and other measures. However, there is one area of electrical energy conservation that has been almost totally overlooked – the energy savings that can be realized by optimizing campus electric distribution voltages. Like many universities across the country, Murray State University (MSU) consistently looks to improve energy efficiency on campus. MSU’s 236-acre main campus is in Murray, KY, a city of approximately 18,000 residents. Founded in 1922, the university has grown from an enrollment of 202 students to 10,400 today. The University buys all its electrical power from Murray Electric System (MES), a municipally owned Tennessee Valley Authority (TVA) distribution utility. In March 2011, Utilidata deployed its AdaptiVolt™ voltage optimization software on Murray State University’s campus. The patented AdaptiVolt™ software has been installed at major electric utilities and industrial facilities in the U.S. and Canada, providing significant energy savings when implementing conservation voltage reduction.

|

|

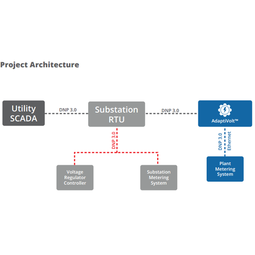

Saving Megawatts with Voltage Optimization

Utilidata

Conservation voltage reduction is the practice of operating electric distribution systems at voltages in the lower range of allowable levels, thereby improving the efficiency of many electric utilization devices (e.g. induction and synchronous motors, transformers, lighting systems, etc.).This approach can be applied to a variety of industrial settings; however, using an advanced real-time control system such as AdaptiVolt™ is critical to ensuring that voltages don’t drop to levels that put important processes at risk. AdaptiVolt™ monitors voltages through the facility in real-time and makes control decisions to safely reduce voltage, thereby achieving energy efficiency gains while maintaining process reliability

|