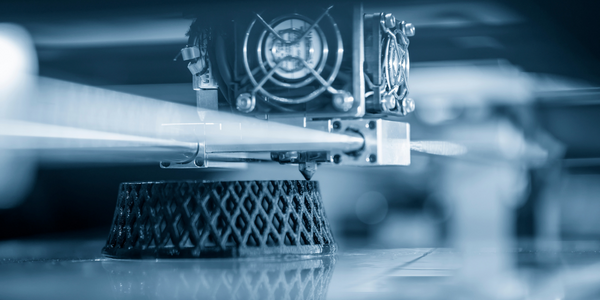

3D-Printing of Tooling Parts

- Equipment & Machinery

- Product Research & Development

- Additive Manufacturing

- Hardware Design & Engineering Services

Selective Laser Melting (SLM), an additive manufacturing technology, can be used for the production of tooling components with conformal cooling channels. ABB OY, Drives and Controls, was able to tremendously reduce the cycle time for a cabling grommet due to a redesign and optimization of a tooling insert. The optimized geometry of the part not only reduces the cycle time but also leads to less scrap parts in production.

The aim of the case study of implementing conformal cooling for this insert was to improve the efficiency of the production and to increase the product quality resulting in less defective products.

For the study, six different channel profiles were designed for the tooling insert, including one resembling a part with conventional cooling to provide a comparison to conventional manufacturing. The channel profiles were optimized for the SLM technology taking into account factors including the angles of surfaces facing down to reduce the need of supports, a minimum wall thickness between channels and the dimensions and shapes of the channels. Before building all the various cooling channel profiles, simulations for water flow and thermal conductivity were carried out and the parts already showed slightly different cooling behavior in the simulations.

The utilization of SLM leads to drastic reduction of cycle time and production cost. Achieving a reduction of the cooling time from around 30 seconds to approximately six seconds was able to reduce the cycle time from 60.5 seconds to 14.7 seconds by using the conformal cooling insert in the injection molding tool.

Related Case Studies.