Digital Change Over

The machines and the spare parts need continuous monitoring and previously the software that client was using was not an effective one.

Therefore, this whole system needs to be modified to smoothen the whole process of manufacturing where analytics, centralized database, and alert system are developed into the software in order to get notified about the critical aspects in the facility.

Email, message, and notification:

Notification to operator and engineer/manager after completion of upgradation of change over sheet with model number and quantity.

Generate notifications if input/scanned data doesn’t match with the database values.

Sheet assigning, sheet completion.

The client is a global company focused on advanced mobility that positively changes how the world moves and contributes to greater well-being. They provide automotive service parts and are leading global supplier to all major automakers in India.

The client owns an Automobile manufacturing facility. The client’s customers include Tata and Toyota among others.

The client has a set of machinery that they want to monitor from a centralized dashboard and database machine change over data logging. Therefore, a solution is proposed where they can line-wise monitor machine models (Model name, quantity, and person performing changeover) with monthly reports.

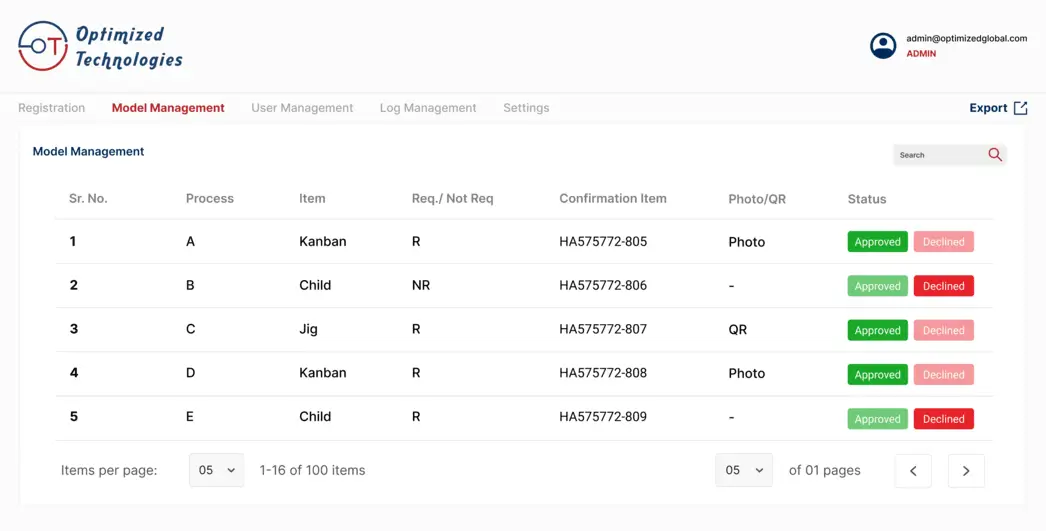

Centralized database and dashboard for data logging and data monitoring for a change-over sheet of machines

Centralized database:

Data history maintenance for tracking changes over time.

User authentication with login credentials.

Granular permissions based on hierarchy for data access.

Centralized storage of multimedia content for various machines and programs.

Automated notifications and document uploads in PDF or Excel formats, with digital signature support.