Download PDF

Enpro Inc. Enhances Quality Control in Carbonated Beverage Filling with HID Global

Technology Category

- Networks & Connectivity - RFID

- Sensors - RFID Readers

Applicable Industries

- Electronics

- Recycling & Waste Management

Applicable Functions

- Quality Assurance

Use Cases

- Onsite Human Safety Management

- Visual Quality Detection

Services

- System Integration

- Testing & Certification

The Challenge

Enpro Inc.'s customers, primarily beverage companies, rely on automated, high-speed filling lines that produce up to 2,500 items per minute per line. A key component of these lines is the vent tube, which is used to fill cans and bottles and vent out the carbonation-related gas. However, due to wear and tear, these vent tubes can occasionally fall off and into the cans and bottles, leading to safety and quality issues. The loss or damage of a vent tube during the filling process can result in large amounts of finished packaged product being discarded, as locating the missing vent tube is a costly and time-consuming process. Therefore, Enpro Inc.'s customers needed a reliable way to detect the presence or absence of a vent tube, eliminating the need for manual checks and potential line halts.

The Customer

Enpro Inc.

About The Customer

Enpro Inc., founded in 1961, is an Illinois-based company that provides patented, state-of-the-art traceable components and systems to reduce waste and downtime associated with the filling process in the food and beverage industry. Their products enable some of the world’s largest manufacturers to reliably and accurately detect malfunctions. Enpro Inc.'s customers are primarily beverage companies that rely on automated, high-speed filling lines for their operations. These customers needed a reliable solution to detect the presence or absence of a vent tube in their filling lines, a challenge that was causing significant operational and quality issues.

The Solution

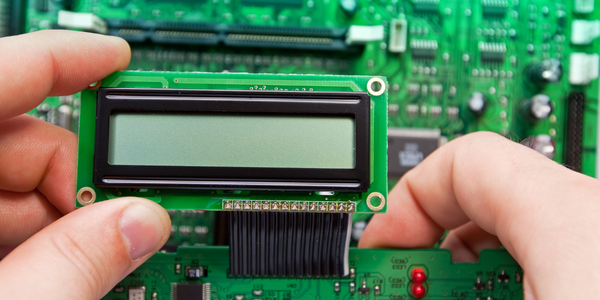

To solve this problem, Enpro Inc. collaborated with the largest beverage manufacturers, HID Global, and FEIG Electronics to develop a Filler Vent Tube Reader (FVTR) for monitoring vent tube fillers. This solution involved a robust HF RFID-powered non-contact monitoring system, supported by a high-frequency reader. The FVTR was built with a custom designed and molded SLIX2 HF Ring Tag from HID Global, which is injection molded into the vent tube. FEIG Electronics provided its LRM2500 High Frequency Reader, coupled with custom developed Enpro electronics. This combined effort resulted in the world’s fastest HF Reading application, capable of reading anywhere from 30-800 tags per second depending on the air protocol and implementation by the silicon manufacturer.

Operational Impact

Quantitative Benefit

Related Case Studies.

Case Study

Remote Temperature Monitoring of Perishable Goods Saves Money

RMONI was facing temperature monitoring challenges in a cold chain business. A cold chain must be established and maintained to ensure goods have been properly refrigerated during every step of the process, making temperature monitoring a critical business function. Manual registration practice can be very costly, labor intensive and prone to mistakes.

Case Study

Cloud Solution for Energy Management Platform-Schneider Electric

Schneider Electric required a cloud solution for its energy management platform to manage high computational operations, which were essential for catering to client requirements. As the business involves storage and analysis of huge amounts of data, the company also needed a convenient and scalable storage solution to facilitate operations efficiently.

Case Study

Leveraging the IoT to Gain a Competitive Edge in International Competition

Many large manufacturers in and outside Japan are competing for larger market share in the same space, expecting a growing demand for projectors in the areas of entertainment, which requires glamor and strong visual performance as well as digital signage that can attract people’s attention. “It is becoming more and more difficult to differentiate ourselves with stand-alone hardware products,” says Kazuyuki Kitagawa, Director of Service & Support at Panasonic AVC Networks. “In order for Panasonic to grow market share and overall business, it is essential for us to develop solutions that deliver significant added value.” Panasonic believes projection failure and quality deterioration should never happen. This is what and has driven them to make their projectors IoT-enabled. More specifically, Panasonic has developed a system that collects data from projectors, visualizes detailed operational statuses, and predicts issues and address them before failure occurs. Their projectors are embedded with a variety of sensors that measure power supply, voltage, video input/ output signals, intake/exhaust air temperatures, cooling fan operations, and light bulb operating time. These sensors have been used to make the projector more intelligent, automatically suspending operation when the temperature rises excessively, and automatically switching light bulbs. Although this was a great first step, Panasonic projectors were still not equipped with any capability to send the data over a network.