Download PDF

HID Global’s Passive RFID Sensor TAGs Revolutionize GE Hydro's Generator Installations

Technology Category

- Networks & Connectivity - RFID

- Sensors - Temperature Sensors

Applicable Industries

- Equipment & Machinery

- Renewable Energy

Applicable Functions

- Human Resources

- Maintenance

Use Cases

- Asset Lifecycle Management

- Structural Health Monitoring

Services

- System Integration

- Testing & Certification

The Challenge

GE Hydro, a subsidiary of GE Renewable Energy, provides solutions for hydropower installations, including machinery and equipment sensor integration, testing, measurements, and data interpretation. However, they faced a significant challenge in monitoring the conditions of their installations. Hydropower installations are located in severe environments, often with aging connections between the rotor poles that exhibit drastic temperature rises and cause unplanned failures in production. Traditional solutions like batteries, direct wired connections, infrared devices, and fiber-based temperature sensors were ineffective due to the harsh conditions, high radial accelerations, and the proximity of metal parts. Furthermore, the high speed of transit in front of the antenna, which can go up to 250 km per hour, posed additional challenges. Monitoring, collecting, and managing reliable data with a small RFID TAG was a major technical challenge due to the high currents and related electromagnetic fields inside the enclosure where the RFID chip in the generator is located.

The Customer

GE Hydro

About The Customer

GE Hydro is a wholly-owned subsidiary of GE Renewable Energy, providing a full range of solutions for small and large hydropower installations. Their services include machinery and equipment sensor integration, testing and measurements, and data interpretation through its Asset Performance Management (APM) platform. GE Hydro’s customers are located around the world and include integrators and government-owned companies, federal utilities, independent power producers, and investors. They operate in severe environments, often dealing with aging connections between the rotor poles of their installations, which can cause drastic temperature rises and unplanned failures in production.

The Solution

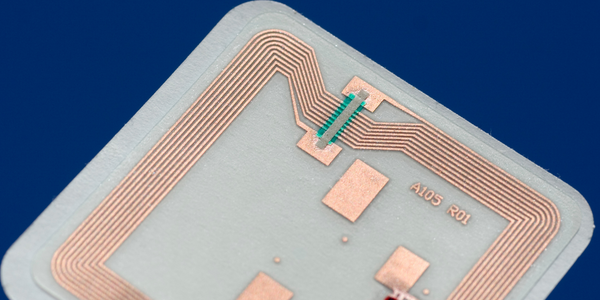

To overcome these challenges, GE Hydro partnered with Asygn, a developer and semiconductor integrated device manufacturer, to use the AS3211 IC that met all of GE Hydro’s requirements. However, to create an industrial-grade solution, the system also needed a properly tuned antenna within the RFID bandwidth capable of powering the complete acquisition chain and components of the chip. HID Global, a TAG provider for the UHF condition monitoring sensors, was enlisted to solve this challenge. They integrated the TAG antenna with the RFID chip to ensure the antenna’s reliability and integrity during the massive radial acceleration of the hydro turbines. The solution encompasses Asygn’s chip, which captures temperature and strain measurements when the HID’s TAG antenna forwards that data to an RFID reader. The RFID reader works as an intelligent gateway capable of calibrating, collecting, filtering, averaging, and transmitting data locally. Data aggregation and modeling happens through GE Hydro’s Asset Performance Management (APM) platform, which uses machine-learning analytics with local context and parameters to avoid any false positive and push erroneous standardization in the model itself.

Operational Impact

Quantitative Benefit

Related Case Studies.

Case Study

Smart Water Filtration Systems

Before working with Ayla Networks, Ozner was already using cloud connectivity to identify and solve water-filtration system malfunctions as well as to monitor filter cartridges for replacements.But, in June 2015, Ozner executives talked with Ayla about how the company might further improve its water systems with IoT technology. They liked what they heard from Ayla, but the executives needed to be sure that Ayla’s Agile IoT Platform provided the security and reliability Ozner required.

Case Study

IoT enabled Fleet Management with MindSphere

In view of growing competition, Gämmerler had a strong need to remain competitive via process optimization, reliability and gentle handling of printed products, even at highest press speeds. In addition, a digitalization initiative also included developing a key differentiation via data-driven services offers.

Case Study

Remote Monitoring & Predictive Maintenance App for a Solar Energy System

The maintenance & tracking of various modules was an overhead for the customer due to the huge labor costs involved. Being an advanced solar solutions provider, they wanted to ensure early detection of issues and provide the best-in-class customer experience. Hence they wanted to automate the whole process.

Case Study

Vestas: Turning Climate into Capital with Big Data

Making wind a reliable source of energy depends greatly on the placement of the wind turbines used to produce electricity. Turbulence is a significant factor as it strains turbine components, making them more likely to fail. Vestas wanted to pinpoint the optimal location for wind turbines to maximize power generation and reduce energy costs.

Case Study

Predictive Maintenance for Industrial Chillers

For global leaders in the industrial chiller manufacturing, reliability of the entire production process is of the utmost importance. Chillers are refrigeration systems that produce ice water to provide cooling for a process or industrial application. One of those leaders sought a way to respond to asset performance issues, even before they occur. The intelligence to guarantee maximum reliability of cooling devices is embedded (pre-alarming). A pre-alarming phase means that the cooling device still works, but symptoms may appear, telling manufacturers that a failure is likely to occur in the near future. Chillers who are not internet connected at that moment, provide little insight in this pre-alarming phase.

Case Study

Premium Appliance Producer Innovates with Internet of Everything

Sub-Zero faced the largest product launch in the company’s history:It wanted to launch 60 new products as scheduled while simultaneously opening a new “greenfield” production facility, yet still adhering to stringent quality requirements and manage issues from new supply-chain partners. A the same time, it wanted to increase staff productivity time and collaboration while reducing travel and costs.