Predictive maintenance in Schneider Electric

- Analytics & Modeling - Machine Learning

- Analytics & Modeling - Predictive Analytics

- Functional Applications - Enterprise Asset Management Systems (EAM)

- Functional Applications - Remote Monitoring & Control Systems

- Sensors - Temperature Sensors

- Sensors - Voltage Sensors

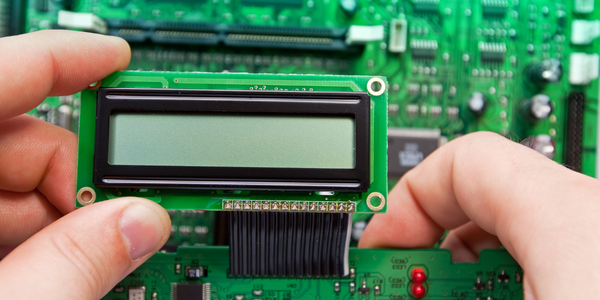

- Electronics

- Maintenance

- Predictive Maintenance

Schneider Electric Le Vaudreuil factory in France is recognized by the World Economic Forum as one of the world’s top nine most advanced “lighthouse” sites, applying Fourth Industrial Revolution technologies at large scale. It was experiencing machine-health and unplanned downtime issues on a critical machine within their manufacturing process. They were looking for a solution that could easily leverage existing machine data feeds, be used by machine operators without requiring complex setup or extensive training, and with a fast return on investment.

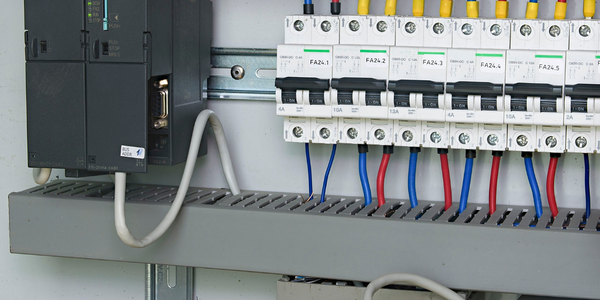

Initially, Schneider Electric ran an analysis on the problematic machine to determine the main cause of the downtime and assess the machine health. After this analysis, they discovered it was partly due to the long timeframe applied for changing old parts. To address this issue Schneider Electric began regularly changing components. However, only 18% of the unplanned downtime was related to the age of components. Based on this, Schneider Electric installed temperature and current sensors to monitor this critical machine’s behavior. The data from these sensors was stored in Aveva Insight, then passed into Senseye PdM to be analyzed against historical data. Using powerful AI and ML algorithms based on mechanical frameworks, Senseye PdM was able to automatically provide maintenance engineers with alerts before the machine would fail. For example, machine operators were notified before a spindle or counter spindle would break giving a 7-point improvement in OEE.

Related Case Studies.