XBee-Enabled Sensors Monitor Harsh Environments

- Networks & Connectivity - Radio Access Network

- Electronics

Libelium needed radio frequency modules to guarantee accurate transmission of information from sensors placed in isolated or difficult-to-access areas. To enable Libelium to develop its sensor devices, the company needed to source a wireless networking provider that offered both long-range links and the interconnection of wireless networks of different frequencies.

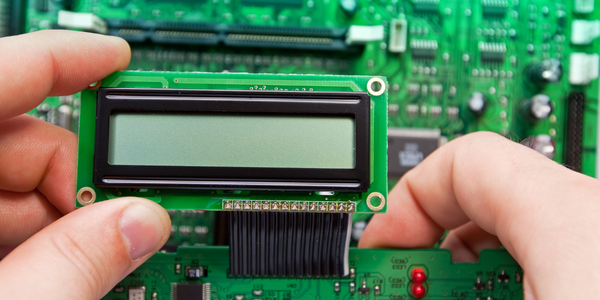

Using XBee modules from Digi as the main communication radios, Libelium developed the Waspmote – a low-power wireless sensor capture, geo-localisation and communication device with high transmission power. Based on a modular architecture, Waspmote is able to detect a variety of parameters such as humidity, temperature, CO2 emissions, heartbeats and vibrations. Waspmote can be used in numerous industries including agriculture, environmental, logistics and security. Hardware Components - XBEE-PRO XSC - XBEE ZIGBEE - Libelium Waspmote - DigiMesh Modules

Related Case Studies.