Case Studies.

Our Case Study database tracks 18,927 case studies in the global enterprise technology ecosystem.

Filters allow you to explore case studies quickly and efficiently.

-

(4)

- (2)

- (2)

- (2)

- View all

-

(3)

- (3)

- (3)

- (1)

- View all

-

(3)

- (2)

- (1)

- (1)

-

(2)

- (1)

- (1)

- (2)

- (1)

- (2)

- (1)

- (1)

- (3)

- (5)

Selected Filters

5 case studies

|

Condition Based Monitoring for Industrial Systems

Advantech B+B SmartWorx

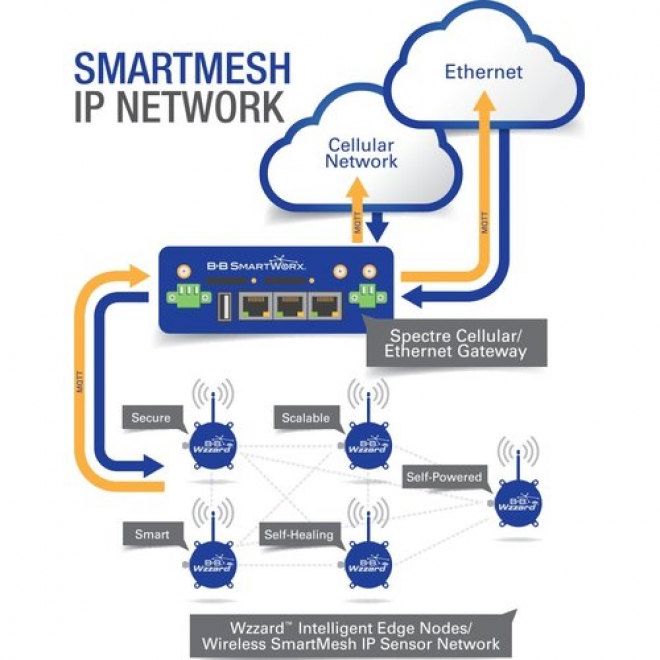

A large construction aggregate plant operates 10 high horsepower Secondary Crusher Drive Motors and associated conveyor belts, producing 600 tons of product per hour. All heavy equipment requires maintenance, but the aggregate producer’s costs were greatly magnified any time that the necessary maintenance was unplanned and unscheduled. The product must be supplied to the customers on a tight time schedule to fulfill contracts, avoid penalties, and prevent the loss of future business. Furthermore, a sudden failure in one of the drive motors would cause rock to pile up in unwanted locations, extending the downtime and increasing the costs.Clearly, preventative maintenance was preferable to unexpected failures. So, twice each year, the company brought in an outside vendor to attach sensors to the motors, do vibration studies, measure bearing temperatures and attempt to assess the health of the motors. But that wasn’t enough. Unexpected breakdowns continued to occur. The aggregate producer decided to upgrade to a Condition Based Monitoring (CBM) sensor system that could continually monitor the motors in real time, apply data analytics to detect changes in motor behavior before they developed into major problems, and alert maintenance staff via email or text, anywhere they happened to be.A wired sensor network would have been cost prohibitive. An aggregate plant has numerous heavy vehicles moving around, so any cabling would have to be protected. But the plant covers 400 acres, and the cable would have to be trenched to numerous locations. Cable wasn’t going to work. The aggregate producer needed a wireless solution.

|

|

Machine Condition Monitoring for a Distribution Center

Advantech B+B SmartWorx

A distribution center used a conveyor belt systems to transport a wide variety of products to appropriate locations. When all went well, products were delivered, stored and shipped back out with a minimum of trouble. But a breakdown in any of the motors running the conveyor belts could interfere with operations and cause unacceptable shipping delays. The distribution center decided to use remote monitoring and decision analytics to predict where and when, preventative maintenance could keep small problems from ballooning into major disruptions.

|

|

IIoT Solution for an Improved Customer Experience

Advantech B+B SmartWorx

A theme park was always looking for ways to enhance the customer experience, and minimizing wait times at attractions and foodservice outlets was one of the key concerns. Tracking and analyzing visitor behavior could potentially let management address it. The first step would be to have the analytics software look at things like advanced ticket sales, weather forecasts and previous attendance records to help management make staffing decisions several days in advance. Collecting and analyzing data could also improve day to day operations. If equipped with the right kinds of information, the control center could make informed decisions about where to place staffing resources. If the line at a water ride was getting too long, management could add staff and launch more boats. If the line at a foodservice station was getting too long, management could send costumed characters to hand out menus and entertain the guests, thus making the wait less painful. To track where visitors were and what they were doing, park management would need to gather data from devices like surveillance cameras, foodservice cash registers, and ticketing machines. But the plan would also require placing some of these devices in locations where trenching and installing new cable connections would be both disruptive and expensive.

|

|

Machine Condition Monitoring for a Caribbean Resort

Advantech B+B SmartWorx

A Caribbean resort has numerous buildings spread out across a scenic campus. One of the company's most important concerns is reliable air conditioning, as guests will be very upset if they are uncomfortable. Downtime is not an option. But if air conditioning equipment fails completely - a compressor, for example - the replacement has to be shipped in from another country at an inflated price. The resort realized that closely monitoring their equipment would enable preventative maintenance, and greatly extend the useful life of their air conditioning systems. But how do you monitor things like pumps and compressors when they have no network interface and they are scattered across a very wide area?

|

|

Reporting Live From Eyjafjallajökull

Advantech B+B SmartWorx

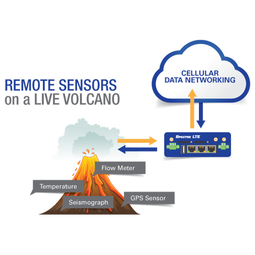

Sensors aren’t always placed in locations that make data networking connectivity easy. One rather extreme example would be the slopes of Iceland’s Eyjafjallajökull volcano, which is capable of making ground travel in the area extremely hazardous. In extreme events, like the eruptions of 2010, Eyjafjallajökull can emit so much ash that it disrupts air travel all over Europe.The Icelandic Meteorological Office observes Eyjafjallajökull with a wide array of sensors ranging from seismographs and GPS units to flow meters and thermometers. They can’t control the volcano, but they can make informed predictions about its behavior.Between lava flows, ash fall and earth tremors, installing and maintaining a data communications cable run on a live a volcano would be a very expensive proposition. The Icelandic Meteorological Office needed a wireless solution that could do its job in a very tough environment.

|