Impinj

Digital Life For Everyday ItemsImpinj wirelessly connects billions of everyday items such as apparel, medical supplies, and automobile parts to consumer and business applications such as inventory management, patient safety, and asset Tracking. The Impinj platform uses RAIN RFID to deliver timely information about these items to the digital world, thereby enabling the Internet of ThingsImpinj, Inc. provides ultra high frequency Radio Frequency Identification (RFID) solutions for identifying, locating, and authenticating items. The company’s products include Indy Reader Chips that include integrated radio chips and supporting SDKs; Monza Tag Chips, which deliver memory options and extended features to RFID tags; and Speedway fixed RFID readers and antennas for RFID-based information. It also provides STP Source Tagging Platform, a platform for the creation of high-performance encoding and verification systems. The company serves retail, asset management, consumer electronics, entertainment, healthcare, Internet of Things, and logistics markets.

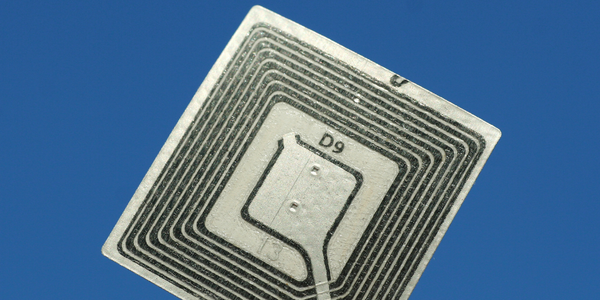

RAIN RFID is a passive (battery-free) wireless technology system that connects billions of everyday items to the Internet, enabling businesses and consumers to identify, locate, authenticate and engage each item. RAIN RFID is used in a wide variety of applications, including inventory management, patient safety, asset Tracking and item Authentication. RAIN is the fastest growing segment of the RFID market and uses a single, global standard: UHF Gen 2 (ISO/IEC 18000-63). RAIN has connected over 20 billion items to date. By providing internet connectivity to and real time information about everyday items such as apparel, medical supplies, automobile parts, food and more, RAIN RFID enables the true Internet of Things.

Intel, Patrizia Pepe Firenze, Exito, Qantas, Hanmi, American Apparel, Cisco, Purdue, memove, KH Lloreda

-

Devices Layer

-

Edge Layer

-

Cloud Layer

-

Application Layer

-

Supporting Technologies

Case Studies.

Similar Suppliers.

.jpg)