Download PDF

RtTech Software

Overview

HQ Location

Canada

Year Founded

2011

Company Type

Private

Revenue

< $10m

Employees

11 - 50

Website

Twitter Handle

Company Description

RtTech Software develops and markets industrial apps that provide operational intelligence.

RtTech offers two main solutions – RtDUET, a real-time software app designed to improve asset availability and utilization in industrial facilities like manufacturing, mining and power generation, and RtEMIS, an energy management information system designed to help industrial facilities reduce energy consumption.

RtTech offers two main solutions – RtDUET, a real-time software app designed to improve asset availability and utilization in industrial facilities like manufacturing, mining and power generation, and RtEMIS, an energy management information system designed to help industrial facilities reduce energy consumption.

Key Customers

AGL, Barrick, Michelin, Cargill, International Power, Nalco, McCain, P&G

IoT Snapshot

RtTech Software is a provider of Industrial IoT application infrastructure and middleware, analytics and modeling, and functional applications technologies, and also active in the mining industries.

Technologies

Use Cases

Functional Areas

Industries

Services

Technology Stack

RtTech Software’s Technology Stack maps RtTech Software’s participation in the application infrastructure and middleware, analytics and modeling, and functional applications IoT Technology stack.

-

Devices Layer

-

Edge Layer

-

Cloud Layer

-

Application Layer

-

Supporting Technologies

Technological Capability:

None

Minor

Moderate

Strong

Case Studies.

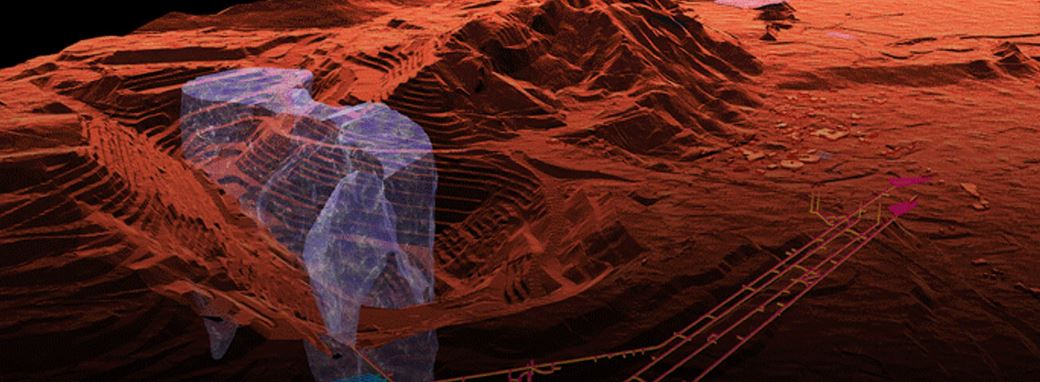

Case Study

Maximizing Plant Utilization

While Argyle Diamond Mine had an existing delay accounting system that was developed in-house, the challenges of a legacy system were exasperated by the departure of the in-house developer. As a result, the company struggled to remain up-to-date with the changes in the mining process along with advances in software capabilities.Due to changes in mining operations, a large number of equipment events were recorded as text data. This made it difficult to search for trends since the system was dependent on user input, which was not consistent across each user.The challenge for Argyle Diamonds was to determine which delay accounting system would be the best to implement given a limited budget and a well-defined set of needs: something scalable, capturing all delays at the plant level, with the ability to classify and search delay events.

Similar Suppliers.

Supplier

Neo4j

Neo4j is the graph company behind the #1 platform for connected data. The Neo4j graph platform helps organizations make sense of their data by revealing how people, processes and digital systems are interrelated. This connections-first approach powers intelligent applications tackling challenges such as Artificial Intelligence, fraud detection, real-time recommendations and master data. The company boasts the world's largest dedicated investment in native graph technology, has amassed more than ten million downloads, and has a huge developer community deploying graph applications around the globe. More than 250 commercial customers, including global enterprises like Walmart, Comcast, Cisco, eBay and UBS use Neo4j to create a competitive advantage from connections in their data. Neo4j is privately held and funded by Eight Roads Ventures (an investment arm of Fidelity International Limited), Sunstone Capital, Conor Venture Partners, Creandum, Dawn Capital and Greenbridge Investment Partners. Headquartered in San Mateo, Calif., Neo4j has regional offices in Sweden, Germany and the UK. For more information, please visit Neo4j.com and @Neo4j. All trademarks and registered trademarks, including Neo4j? are the property of their respective owners.

Supplier

Industrial Network Systems

INS has spent years providing our manufacturing and industrial clients with best-in-class solutions to improve their overall business performance. By recognizing our clients have individual needs we have successfully applied over 3,500 software, hardware and training solutions that were focused on collecting, coordinating and synchronizing plant information throughout the entire enterprise. INS was started solely to supply our customers with scalable factory automation solutions that deliver increased productivity and ROI from the plant floor and throughout the enterprise. Our focus is on providing solutions that collect, distribute, control and provide visualization of information from the plant floor and throughout the enterprise.