Download PDF

WIN-911

The Most Widely Used Alarm Notification Platform in the Industrial Internet of Things

Overview

HQ Location

United States

Year Founded

1983

Company Type

Private

Revenue

$10-100m

Employees

11 - 50

Website

Twitter Handle

Company Description

WIN-911 is the world’s largest Industrial Internet of Things (IIoT) company dedicated to adding mobility to automation systems used in public infrastructure, manufacturing, oil & gas, building management, and other industries. WIN-911 is used in over 10,000 facilities, in seventy countries.

IoT Solutions

One of WIN-911’s chief functions is to leverage the IIoT environment to filter, escalate, and route machine alarms to appropriate personnel and devices in an operationally intelligent manner. WIN-911 easily integrates with most control software (SCADA, HMI and/or DCS) systems in the marketplace.

With WIN-911, operators can concentrate on other tasks while the system does the monitoring. 189 of the Fortune 500 companies and 118 of the Global 500 companies use WIN-911 to manage alarm notification.

With WIN-911, operators can concentrate on other tasks while the system does the monitoring. 189 of the Fortune 500 companies and 118 of the Global 500 companies use WIN-911 to manage alarm notification.

Key Customers

Coca-Cola, Pepsico, Ocean Spray, Dean Foods, Sara Lee, Kraft, USS, 3M, Alcoa, Ford, GM, P&G, Texas Instrument, Bridgestone, Caterpillar, Exxon Mobil, Marathon Oil, Chevron, Halliburton, OXY, Duke Energy, Abbott, Merck, Amgen, Bristol-Myers Squibb, Lilly, Biogen idec, City of College Station, NASA, Fermilab, Delta Airlines, Sydney Airport, Boeing, US Army

IoT Snapshot

[Vendor_Name] is active in the aerospace, food and beverage, life sciences, mining, and oil and gas industries.

Use Cases

Functional Areas

Industries

Technology Stack

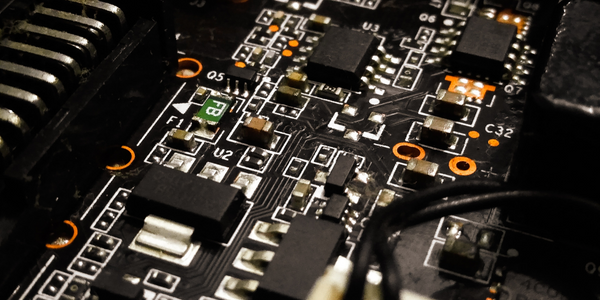

WIN-911’s Technology Stack maps WIN-911’s participation in the IoT Technology stack.

-

Devices Layer

-

Edge Layer

-

Cloud Layer

-

Application Layer

-

Supporting Technologies

Technological Capability:

None

Minor

Moderate

Strong

Case Studies.

Case Study

ELI LILLY ADOPTS MICROMEDIA’S ALERT NOTIFICATION SYSTEM

Pharmaceutical production is subject to a strict set of enforced rules that must be adhered to and compliance to these standards is critically necessary. Due to the efforts of WIN 911’s strategic partner Micromedia, Lilly was able to adopt an alarm notification infrastructure that integrated smoothly with their existing workflows and emergency hardware and protocols. These raw energy sources enable the industrial process to function: electricity, WIN-911 Software | 4020 South Industrial Drive, Suite 120 | Austin, TX 78744 USA industrial steam, iced water, air mixtures of varying quality. Refrigeration towers, boilers and wastewater are monitored by ALERT. Eli Lilly identified 15000 potential variables, but limitations compelled them to chisel the variable list down to 300. This allowed all major alarms to be covered including pressure, discharge, quantity of waste water discharged,temperature, carbon dioxide content, oxygen & sulphur content, and the water’s pH.

Case Study

STMICROELECTRONICS INTEGRATES ALARM NOTIFICATION INTO ITS PRODUCTION CONTROL PRO

Semiconductor production environments are “clean rooms” and must be tightly monitored in order to reduce the possibility of product contamination. A dusty environment will almost certainly lead to quality control issues. In order to prevent such disasters, STMicroelectronics installed a data monitoring and centralization system that instantly recognizes a problem and alerts the appropriate people.

Similar Suppliers.

Supplier

Webdyn

Webdyn is the brand of Flexitron Group dedicated to design and manufacture industrial IoT solutions, routers, modems and gateways for wireless communication GSM (LTE / 4G / 3G / 2G), wired (RS232, RS485, Ethernet or CAN) and short-range wireless (Bluetooth) , Wi-Fi or LoRa).With more than 30 years of experience, Flexitron Group provides the best technological devices and services through its subsidiaries, developing connected solutions adapted to international markets and customers.We designed our product portfolio to help our partners access opportunities within the rapidly growing IoT and Industrial IoT environment. We propose IoT modems, gateways and routers for all your IoT applications. From automation, metering or photovoltaic, to public transport connectivity – hundreds of thousands of our networking devices are currently at the heart of our partners’ IoT solutions.

Supplier

Rovisys

We founded RoviSys as an independent control system integrator because we felt systems owners wanted those freedoms, to be enabled, not restrained.Since its founding in 1989 as one of the first control systems integrators in North America, RoviSys has evolved to become a leading independent provider of comprehensive process automation solutions and services.With the resources, experience and skills to solve and support practically any process automation and integration challenge, the company’s more than 500 engineers, developers and project managers make RoviSys an excellent choice for companies of all sizes looking for real solutions.RoviSys is a control system integrator and product development company with a foot planted firmly in the old and the new worlds of technology. Our engineers and developers know proprietary systems: Before joining RoviSys, many of them created some of the most successful large-scale control systems of the last decade.But more than a decade ago, these same engineers and product developers recognized that companies investing in the most proprietary of systems wanted something more-- the freedom to choose the best available technologies and solutions with alternatives for support and upgrades. In short, they wanted open systems. RoviSys was founded in 1989 to fulfill those wants.The RoviSys commitment is simple: provide clients with world class information integration and process controls using the best available components and platforms, regardless of who makes them. In short, give clients choices.RoviSys has the resources and skills to solve and support practically any process automation, manufacturing information and integration challenge. This breadth of resources and depth of experience makes RoviSys an excellent choice for companies looking for advanced and proven solutions. The company's offices are located near Cleveland, OH, Raleigh, NC, Boston, MA, Houston, TX, and Singapore.