Download PDF

Xerafy

Powering Industrial IoT

Overview

HQ Location

Singapore

Year Founded

2009

Company Type

Private

Revenue

$10-100m

Employees

51 - 200

Website

Twitter Handle

Company Description

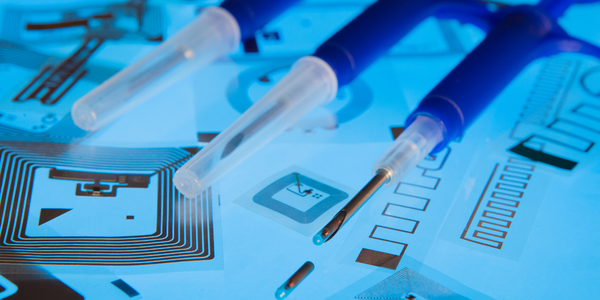

Xerafy designs and manufactures the world's toughest RFID tags to power Industrial IoT applications in Manufacturing, Aerospace, Oil & Gas, Automotive, and Healthcare. A member of RAIN RFID, our technology has been distinguished by EY, Frost & Sullivan, AIconics, and Red Herring. Xerafy operates in the Americas, EMEA, and Asia Pacific regions. The Xerafy team came together to develop a breakthrough Radio Frequency Identification (RFID) design. Unlike others, it would take advantage of the metal in its surrounding, instead of being limited by it.

IoT Solutions

Asset Tracking, Identification, Counting, Analyzing, Monitoring: Businesses get the data they need to drive performance and flexibility with Xerafy's passive UHF RFID tagging and sensing solutions, available for all types of enterprise assets ranging

Key Customers

Xerafy serves clients from numerous industries ranging from manufacturing such as German firm Rittal to the energy sector such as the Centre Nucléaire de Production d’Electricité (CNPE) to even schools like Columbia University.

IoT Snapshot

Xerafy is a provider of Industrial IoT networks and connectivity, sensors, and functional applications technologies, and also active in the healthcare and hospitals, oil and gas, renewable energy, and utilities industries.

Technologies

Use Cases

Functional Areas

Industries

Technology Stack

Xerafy’s Technology Stack maps Xerafy’s participation in the networks and connectivity, sensors, and functional applications IoT Technology stack.

-

Devices Layer

-

Edge Layer

-

Cloud Layer

-

Application Layer

-

Supporting Technologies

Technological Capability:

None

Minor

Moderate

Strong

Case Studies.

Case Study

RFID Cuts Asset Tracking Time by 70 percent at Nuclear Power Plant

In the CNPE power plant there are numerous large, portable metal containers that house sensitive equipment and have to be subject to regular internal and regulatory inspections for safety and security. As a result, a facility operator has the challenging task of keeping track of the movement of these containers at all times.