下载PDF

Accelerating Time-to-Market: Volvo Trucks North America's Digital Transformation with Digizuite

技术

- 网络与连接 - 5G

- 平台即服务 (PaaS) - 应用开发平台

适用行业

- 电子商务

- 生命科学

适用功能

- 物流运输

- 销售与市场营销

用例

- 最后一英里交付

- 时间敏感网络

挑战

沃尔沃卡车北美公司是沃尔沃集团卡车的一个部门,尽管享有盛誉,但仍面临着巨大的营销挑战。该公司面临内部协作差距以及与经销商网络的沟通问题,这阻碍了其销售潜力。 IT 部门还承担着为其电子商务平台准备图像的耗时任务,这有利于售后零件销售。这些沟通和信息差距以及其他物流挑战阻碍了整个北美组织的沃尔沃卡车团队充分发挥销售和利润潜力。

关于客户

沃尔沃卡车北美公司是沃尔沃集团卡车公司的北美分部,沃尔沃集团卡车公司是沃尔沃的卡车制造业务。该公司生产各种公路和职业 8 级车辆,并通过经销商网络以及领先的零部件和服务计划为新车和二手沃尔沃卡车提供支持。沃尔沃卡车北美公司总部位于北卡罗来纳州格林斯博罗,拥有 10,000 多名员工,年收入约 9 亿美元。

解决方案

为了应对这些挑战,沃尔沃卡车北美公司于 2019 年底实施了 Digizuite DAM(数字资产管理),并将其与 Sitecore CMS(内容管理解决方案)集成。该技术为快速内容制作和分发提供了必要的工具,使营销人员能够有效地将营销资产分发到整个经销商网络。 Digizuite DAM 充当集中式品牌和媒体库,使销售代表能够轻松快速地获取更新内容。该平台还实现了水印和图像格式化流程的自动化,每月节省了无数工时,并减少了在 PartsAsist 网站上显示所有可供购买的零件的时间。

运营影响

数量效益

相关案例.

Case Study

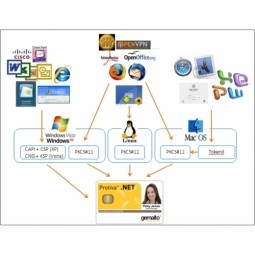

Corporate Identity Solution Adds Convenience to Beckman Coulter

Beckman Coulter wanted to implement a single factor solution for physical and remote logical access to corporate network. Bechman Coulter's users were carrying smart card badges for doors, but also needed a one-time password token to access to our corporate network when they were not in the office. They wanted to simplify the process.

Case Study

Embracing Business Success in Real Time

· Increase control over growing Big Data to improve business decisions · Manage data for 28,000 biotechnology stockkeeping units in the fields of microbiology, molecular biology, animal cell cultures, plant tissue cultures, and lab ware for laboratory chemicals · Accelerate report generation and analysis with real-time data

Case Study

Digital Transformation of Atlanta Grout & Tile: An IoT Case Study

Atlanta Grout & Tile, a Tile, Stone & Grout restoration company based in Woodstock, Georgia, was facing challenges with its traditional business model. Despite steady growth over the years, the company was falling behind the web revolution and missing out on the opportunity to tap into a new consumer base. They were using independent software from different vendors for each of their department information and workforce management. This resulted in a lot of manual work on excel and the need to export/import data between different systems. This not only increased overhead costs but also slowed down their response to clients. The company also had to prepare numerous reports manually and lacked access to customer trends for effective business decision-making.

Case Study

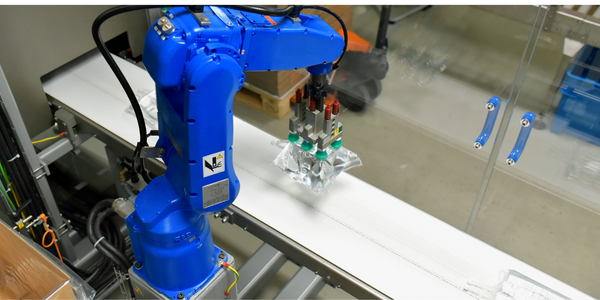

Flow Robotics: Scaling Up Production and Accelerating Product Development with IoT

Flow Robotics, a Danish manufacturer, developed flowbot™ ONE pipetting robots to alleviate the strain on bioanalysts in life-science laboratories and hospitals across Europe. These robots were designed to automate part of the testing process, speeding up the time it takes to produce results and reducing pressure on staff. However, the company faced challenges in scaling up production and accelerating product development. High workloads and physically challenging conditions have long been an issue for laboratory professionals. Flow Robotics estimates that around half of medical lab technicians carry out the same arm movements for at least a quarter of their working day. The American Society for Clinical Pathology reported that 85% of laboratory professionals feel burnt out; 36% struggle with inadequate staffing; and 32% face a heavy workload and pressure to complete all testing on time.

Case Study

IFFCO Boosts IT Performance and Innovates Agriculture with Oracle Cloud

Indian Farmers Fertiliser Cooperative Ltd. (IFFCO), the world’s largest manufacturer and marketer of fertilizers in the cooperative sector, was facing several challenges in its quest to innovate and improve the livelihood of farmers in India. The organization had recently launched a new product, nano urea, which brought new demands to IFFCO’s cloud computing needs. The organization needed a reliable cloud vendor to support the processes of 6–7 new manufacturing plants during the upcoming year, enhancing its production capability 300–350 million bottles of nano urea to meet increasing demand. IFFCO’s cloud adoption was driven by a need to innovate. The organization wanted capabilities for a dynamic business that can adapt to the changing needs of the market while growing fast. However, it was inhibited by rigid on-premises data center deployments and the overhead of maintaining legacy systems. IFFCO wanted to apply the elasticity and availability of cloud for improving overall performance of applications at lowest possible operational overhead. Lastly, IFFCO needed to provide the benefits of its technology to all its stakeholders, including employees, members, transporters, and farmers, some of whom have limited literacy. To accommodate all stakeholders, IFFCO wanted to add a voice interface to its applications.

Case Study

Revolutionizing Aerospace Industry with 3D Printing: A 63% Lighter Titanium Part

GE Aviation, a renowned name in the aerospace industry, recognized the potential of 3D printing technology in transforming the sector. The primary challenge was to reduce the weight of the aerospace parts, which would directly impact the fuel costs. A lighter airplane would mean lower fuel consumption, leading to cost savings and a smaller carbon footprint. However, achieving this weight reduction without compromising the strength and functionality of the parts was a significant challenge. Traditional manufacturing methods were not able to provide the desired weight reduction while maintaining the required stiffness and strength of the parts. The challenge was to find a solution that could create strong, light, and functional aerospace parts.