下载PDF

Innovative Golf Club Design through IoT: Wilson's Driver vs. Driver Competition

技术

- 分析与建模 - 数字孪生/模拟

- 传感器 - 液位传感器

适用行业

- 服装

- 消费品

适用功能

- 产品研发

用例

- 驾驶员表现监测

- 虚拟原型与产品测试

挑战

Wilson Sporting Goods Co. 是一家领先的高性能运动器材制造商,面临着为高尔夫球杆设计电视节目“Driver vs. Driver”中的参赛者提供支持的挑战。该展会旨在鼓励高尔夫行业的创新,让有抱负的高尔夫球杆设计师竞相开发获胜的设计,最终将成为威尔逊的下一个发球杆。我们面临的挑战是为参赛者提供必要的工具和专业知识,将他们的设计变为现实,同时确保设计在技术上合理,并在外观、感觉和性能方面满足消费者的高期望。体育行业的竞争日益激烈,以及对更快、更轻、更强的设备的需求不断增长,增加了挑战的复杂性。

关于客户

Wilson Sporting Goods Co. 是 Amer Sports Corporation 的子公司,是世界领先的高性能运动器材、服装和配件制造商。该公司总部位于伊利诺伊州芝加哥,自 1914 年以来一直致力于帮助世界各地的运动员发挥真正的潜力。Wilson 利用最先进的运动技术和专业知识发明、设计和制造改变游戏规则的产品。他们研究运动员与其装备之间的关系,并在整个开发过程中牢记这一点。威尔逊提出了电视竞赛“Driver vs. Driver”的概念,以鼓励高尔夫行业的创新。

解决方案

威尔逊与他们之前曾合作过成功项目的 Altair 公司合作,协助该节目的开发。 Altair 的技术和工业设计团队在 Wilson Labs 的指导下工作。他们利用虚拟设计技术快速探索概念并优化空气动力学。 Altair ProductDesign 工业设计师和计算流体动力学 (CFD) 专家使用了solidThinking Evolve,这是一种设计工具,可以根据草图和想法快速进行概念开发和创建数字模型。该工具在使参赛者和设计师探索多种结构和美学迭代方面发挥了关键作用。 Altair HyperWorks 的虚拟风洞 (VWT) 是一款专门为模拟和分析给定物体的空气动力学而开发的 CFD 工具,用于分析初始设计的空气动力学性能。这使得参赛者能够对他们的设计进行重大改进。

运营影响

数量效益

相关案例.

Case Study

Fire Alarm System and Remote Monitoring Sytem

Fire alarm systems are essential in providing an early warning in the event of fire. They help to save lives and protect property whilst also fulfilling the needs of insurance companies and government departments.Fire alarm systems typically consist of several inter-linked components, such as smoke detectors, heat detector, carbon monoxide, manual call points, sounders, alarm and buzzer. The fire alarm system should give immediate information in order to prevent the fire spread and protect live and property.To get maximum protection a shoe manufacturer in Indonesia opted for a new fire alarm system to monitor 13 production sites spread over 160 hectars. Although the company had an existing fire alarm system, it could not be monitored remotely.It was essential that the new system would be able to be monitored from a central control room. It needed to be able to connect to the existing smoke detector and manual call point. Information should be easily collected and passed on to the Supervisory Control and Data Acquisition (SCADA) system. Furthermore, the system should have several features such as alarm management, auto reporting, being connected to many client computers without additional cost, and run 24/7 without fails. The company also needed a system which could be implemented without changing the architecture of the existing fire alarm system.

Case Study

IoT Applications and Upgrades in Textile Plant

At any given time, the textile company’s manufacturing facility has up to 2,000 textile carts in use. These carts are pushed from room to room, carrying materials or semi-finished products. Previously, a paper with a hand-written description was attached to each cart. This traditional method of processing made product tracking extremely difficult. Additionally, making sure that every cart of materials or semi-finished products went to its correct processing work station was also a problem. Therefore, the company desired an intelligent solution for tracking assets at their factories. They also wanted a solution that would help them collect process data so they could improve their manufacturing efficiency.

.png)

Case Study

Improving Vending Machine Profitability with the Internet of Things (IoT)

The vending industry is undergoing a sea change, taking advantage of new technologies to go beyond just delivering snacks to creating a new retail location. Intelligent vending machines can be found in many public locations as well as company facilities, selling different types of goods and services, including even computer accessories, gold bars, tickets, and office supplies. With increasing sophistication, they may also provide time- and location-based data pertaining to sales, inventory, and customer preferences. But at the end of the day, vending machine operators know greater profitability is driven by higher sales and lower operating costs.

Case Study

Series Production with Lot-size-1 Flexibility

Nobilia manufactures customized fitted kitchens with a lot size of 1. They require maximum transparency of tracking design data and individual processing steps so that they can locate a particular piece of kitchen furniture in the sequence of processes.

Case Study

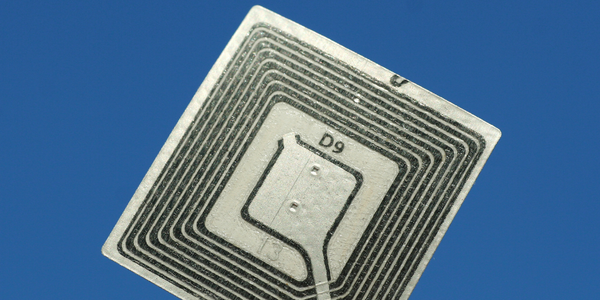

Retailer Uses RFID Scanner to Improve Efficiency

Patrizia Pepe wished to improve the logistics of their warehouse: accepting incoming goods from their production sites, movement of items throughout

the warehouse, and packaging of goods for distribution to the retail locations. They initially tried to use barcodes for this function. Because barcodes must be individually scanned within a line-of-sight, the acceptance of goods coming into the warehouse was too time consuming. Working with the University of Florence, Patrizia Pepe instituted a five-month pilot project beginning in August of 2009 to test the validity of an RFID solution. The pilot involved tagging of about 60,000 items for the second seasonal collection, and convinced the company to move forward with tagging all items.