下载PDF

Unilever's Journey to Optimizing Packaging Designs & Reducing Prototype Costs with IoT

适用行业

- 生命科学

- 包装

适用功能

- 产品研发

用例

- 智能包装

- 制造过程模拟

挑战

联合利华是消费品行业的全球领导者,一直在寻求保持其在男性美容市场创新优势的方法。该公司特别注重将其 Lynx (Axe) 品牌与竞争对手区分开来。我们面临的挑战是设计一种在市场上脱颖而出的新除臭剂包装概念。然而,联合利华缺乏必要的内部专业知识来采用模拟和分析方法来设计和测试新罐。他们需要一个开发合作伙伴来协助新包装概念的设计和测试。

关于客户

联合利华是一家跨国消费品公司,业务遍及 190 多个国家。该公司的产品组合包括食品、饮料、清洁剂和个人护理产品。联合利华以其对创新的承诺而闻名,并不断寻求使其产品与竞争对手区分开来的方法。在这种情况下,该公司专注于增强其流行的男性美容产品线 Lynx (Axe) 品牌。我们面临的挑战是设计一种在市场上脱颖而出的新除臭剂包装概念,但联合利华缺乏必要的内部专业知识来采用模拟和分析方法来设计和测试新罐。

解决方案

联合利华与 Altair ProductDesign 合作应对这一挑战。最初的除臭剂罐设计概念是由联合利华创建的,Altair ProductDesign 进行优化来定义材料布局,以加固盖子按钮并优化通过罐侧壁的负载路径。然后开发了一个更详细的模型来研究一系列“假设”场景,例如载荷值、几何形状变化和材料选项。该过程确定了整个盖子的加固区域,并测量了不同材料特性对刚度和应力的影响。然后根据制造成本对这些进行排名,为材料选择决策提供有价值的指标。 Altair ProductDesign 还为联合利华配备了一套专为包装设计开发的新流程工具。 “Atlas”系统是与联合利华能力开发团队密切合作历时 4-5 年开发出来的,使联合利华的 CAD 和概念设计师能够在设计过程的早期进行分析研究。

运营影响

数量效益

相关案例.

Case Study

IoT Data Analytics Case Study - Packaging Films Manufacturer

The company manufactures packaging films on made to order or configure to order basis. Every order has a different set of requirements from the product characteristics perspective and hence requires machine’s settings to be adjusted accordingly. If the film quality does not meet the required standards, the degraded quality impacts customer delivery causes customer dissatisfaction and results in lower margins. The biggest challenge was to identify the real root cause and devise a remedy for that.

Case Study

Zenon the Ideal Basis for An Ergonomic HMI

KHS develops and produces machines and equipment for filling and packaging in the drinks industry. Because drinks manufacturing, filling and packaging consist of a number of highly complex processes, the user-friendly and intuitive operation of equipment is increasingly gaining in significance. In order to design these processes as simple as possible for the user, KHS decided to introduce a uniform, transparent and standardized solution to the company. The HMI interface should meet the requirement for people with different qualifications and enable them to work on a standard platform.

Case Study

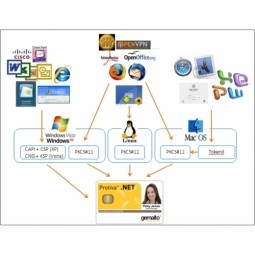

Corporate Identity Solution Adds Convenience to Beckman Coulter

Beckman Coulter wanted to implement a single factor solution for physical and remote logical access to corporate network. Bechman Coulter's users were carrying smart card badges for doors, but also needed a one-time password token to access to our corporate network when they were not in the office. They wanted to simplify the process.

Case Study

Sparks Dynamics Assists Atlas Container Secure a $15,000 BGE Energy Rebate

The ReMASTER Compressed Air Monitoring system was installed in 2015. This system is capable of monitoring compressed air system parameters on a continuous basis and transferring that information to a cloud server which can be accessed by Atlas Container personnel, Industrial Diagnostics and Sparks Dynamics. This information was collected into a database which can be exported to an Excel spreadsheet or displayed graphically using Sparks Dynamics ViewMaster Software. The average annual compressed air electricity expense was estimated to be approximately $116,000. This is based on an incremental $/KWh electric rate of $.091 per KWh and an estimated compressed air energy consumption of 1,279,200 KWH. The implementation phase of Energy Conservation Measures (ECMs) for the Compressed Air System included: • Identification and repair of compressed air leaks • Understanding of compressed air usage per manufacturing machine and installation of shut off valves when the machines are no longer in production mode • Identification of misapplications of compressed air to include blow offs, venturis, and cooling scenarios • Understand system pressure requirements and potential installation of point of use pressure regulation.

Case Study

Automated Pallet Labeling Solution for SPR Packaging

SPR Packaging, an American supplier of packaging solutions, was in search of an automated pallet labeling solution that could meet their immediate and future needs. They aimed to equip their lines with automatic printer applicators, but also required a solution that could interface with their accounting software. The challenge was to find a system that could read a 2D code on pallets at the stretch wrapper, track the pallet, and flag any pallets with unread barcodes for inspection. The pallets could be single or double stacked, and the system needed to be able to differentiate between the two. SPR Packaging sought a system integrator with extensive experience in advanced printing and tracking solutions to provide a complete traceability system.

Case Study

Mondi Implements Statistics-Based Health Monitoring and Predictive Maintenance

The extrusion and other machines at Mondi’s plant are large and complex, measuring up to 50 meters long and 15 meters high. Each machine is controlled by up to five programmable logic controllers (PLCs), which log temperature, pressure, velocity, and other performance parameters from the machine’s sensors. Each machine records 300–400 parameter values every minute, generating 7 gigabytes of data daily.Mondi faced several challenges in using this data for predictive maintenance. First, the plant personnel had limited experience with statistical analysis and machine learning. They needed to evaluate a variety of machine learning approaches to identify which produced the most accurate results for their data. They also needed to develop an application that presented the results clearly and immediately to machine operators. Lastly, they needed to package this application for continuous use in a production environment.