下载PDF

Werma

概述

公司介绍

简单有效的巧妙解决方案——这是我们 WERMA 几十年来的目标,来自世界各地的客户日复一日地证实了我们的成功。我们正在为现代信号技术设定标准,同时也在定义它们的未来:二十多年来,模块化信号塔作为行业标准,如今采用联网的智能系统解决方案。因此,“德国制造”标签是一种保证,现在我们可以自豪地将自己描述为“欧洲领先的信号”。此帐号由 WERMA (Shanghai) Co., Ltd. 更新。

物联网解决方案

WERMA 的 SmartMONITOR 有助于使加工人员更精简、更快、更高效。基于无线的数据收集和传输系统易于改造,并能够分析运营情况,这反过来又会带来未开发的增长潜力,让您在竞争中领先一步。了解有关 WERMA 的 SmartMONITOR 系统的更多信息:werma.wistia.com/medias/c9i502vem4

技术栈

Werma的技术栈描绘了Werma在等物联网技术方面的实践。

-

设备层

-

边缘层

-

云层

-

应用层

-

配套技术

技术能力:

无

弱

中等

强

实例探究.

Case Study

Call for action immediately in Siemens

In line with their Industry 4.0 development initiative, the Siemens factory in Nanjing felt that using phone calls as the primary method for reporting and calling for action was not acceptable for long-term development goals. In addition, phone calls do not create any data that can be stored for future referencing.

Case Study

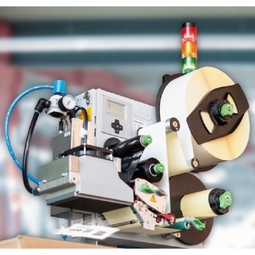

"cab" Selects Signal Towers from WERMA

Clearly identifiable labelling and product marking is an essential part of any business whether it is on individual components, finished products or packaging. Europe's largest manufacturer of labelling and printing machines, supports its reputation for innovation, reliability and durability by the careful selection of essential bought in components for its own operation. This is why cab selected the new innovative modular signal tower series KombiSIGN 40 from WERMA.

同类供应商.

Supplier

congatec AG

congatec AG offers a product portfolio that is comprised of embedded computer modules based on the most common form factors such as Qseven, COM Express and ETX/XTX. congatec also provides professional board support packages, extensive design-in support and specialized embedded BIOS features for industrial use.

Supplier

Quant Service

Quant Service is a global leader in industrial maintenance. For over 25 years, we have been realizing the full potential of maintenance for our customers. From embedding superior safety practices and building a true maintenance culture, to optimizing maintenance cost and improving plant performance, our people make the difference.

Supplier

Princeps

PRINCEPS is an R&D intensive company. We have conducted a significant R&D effort in cooperation with academic organisations in Europe (PRINCEPS is the initiator and coordinator of several EU funded projects).Strong with more than 15 years field experience through planning and scheduling projects worldwide, we have developed an innovative software suite which introduces a new paradigm in this domain.Most importantly, PRINCEPS has developed over the years, a strong working partnership with its clients, which is at the foundation of its customer oriented culture.The Oil industry is one of the pioneers in the widespread adoption of optimization techniques. The term “Refinery optimization” has consequently evolved to become a multi-faceted concept.At an abstract level, refinery optimization is about getting the most from the existing assets; by extension, it can also refer to the most profitable investments in new equipment or new assets. This first distinction gives rise to 2 horizons of application to refinery optimization: long term, structural optimization, and short term operations optimization. Moreover, operations management itself can be addressed in a variety of ways, depending on whether the approach taken to refinery optimization is bottom-up, or top-down:The top-down approach is based on hierarchical optimization: the refinery optimization problem is addressed as a succession of optimization problems of different time magnitudes and granularities. The first problem is a mid-term planning problem and is concerned with the refinery as a whole and a time frame of one to several months. Subsequently, the time frame is subdivided into finer time intervals. At the lowest level, the theoretical goal is to achieve operations scheduling on a day to day basis.The bottom-up approach is one that starts with local problems and tries to aggregate them into a consistent solution at the refinery level.In contrast to traditional bottom-up approaches – which attempt to build an overall solution by aggregating local solutions – we start by achieving a feasible, “good quality” overall solution using our smart simulation engine. Then, guided by the consistent overall solution, we seek to optimize local operational challenges.Our innovative approach to refinery optimization takes account of 2 crucial facts:- Day-to-day operations are subject to uncertainty,- Regardless of the inherent formal difficulty of achieving an overall refinery schedule optimization, an overall optimized schedule is of little use.This is simply because an overall solution achieved that way is inherently unstable: the slightest change or unforeseen event means that the whole schedule must be rebuilt. And given the huge amount of inertia in such a large system, any sudden change of trajectory consumes an equally huge amount of energy.Under this pragmatic perspective, refinery optimization appears as the search for a maintainable globally feasible, locally optimized schedule. Optimization is applied to sub-systems where a high economic impact is achievable.