дёӢиҪҪPDF

е·ҘеҺӮиҝҗиҗҘеҸҜи§ҒжҖ§е’ҢжҷәиғҪ

жҰӮиҝ°

еҸҜи§ҶеҢ–е·ҘеҺӮиҝҗиҗҘж•°жҚ®жҳҜеҪ“д»Ҡи®ёеӨҡеҲ¶йҖ е•Ҷйқўдёҙзҡ„жҢ‘жҲҳгҖӮдёҖдәӣеҲ¶йҖ е•Ҷд»ҠеӨ©жӯЈеңЁжҺЁиЎҢзҡ„ IIoT и®ЎеҲ’д№ӢдёҖжҳҜжҸҗдҫӣе·ҘеҺӮиҝҗиҗҘе’ҢжңәеҷЁеҒҘеә·зҠ¶еҶөзҡ„е®һж—¶еҸҜи§ҒжҖ§гҖӮзӣ®ж ҮжҳҜжҸҗй«ҳеҲ¶йҖ ж•ҲзҺҮгҖӮжҢ‘жҲҳеңЁдәҺз»„еҗҲе’Ңе…іиҒ”еңЁжҖ§иҙЁгҖҒжқҘжәҗе’Ңз”ҹе‘Ҫе‘Ёжңҹж–№йқўе·®ејӮеҫҲеӨ§зҡ„дёҚеҗҢж•°жҚ®жәҗгҖӮе·ҘеҺӮиҝҗиҗҘеҸҜи§ҶжҖ§е’ҢжҷәиғҪ (FOVI) ж—ЁеңЁж”¶йӣҶе·ҘеҺӮиҪҰй—ҙз”ҹжҲҗзҡ„дј ж„ҹеҷЁж•°жҚ®гҖҒз”ҹдә§и®ҫеӨҮж—Ҙеҝ—гҖҒз”ҹдә§и®ЎеҲ’е’Ңз»ҹи®Ўж•°жҚ®гҖҒж“ҚдҪңе‘ҳдҝЎжҒҜпјҢ并е°ҶжүҖжңүиҝҷдәӣдҝЎжҒҜе’Ңе…¶д»–зӣёе…ідҝЎжҒҜйӣҶжҲҗеҲ°дә‘дёӯгҖӮйҖҡиҝҮиҝҷз§Қж–№ејҸпјҢе®ғеҸҜд»Ҙз”ЁжқҘдёәз”ҹдә§и®ҫж–ҪеёҰжқҘеҸҜи§ҒжҖ§пјҢеҲҶжһҗе’Ңйў„жөӢз»“жһңпјҢ并ж”ҜжҢҒжӣҙеҘҪзҡ„ж”№иҝӣеҶізӯ–гҖӮ

йҖӮз”ЁиЎҢдёҡ

- йҮҚеһӢиҪҰиҫҶ

- жұҪиҪҰ

йҖӮз”ЁеҠҹиғҪ

- зҰ»ж•ЈеҲ¶йҖ

еёӮеңә规模

е·ҘдёҡжҺ§еҲ¶е’Ңе·ҘеҺӮиҮӘеҠЁеҢ–еёӮеңәйў„и®Ўе°Ҷд»Һ 2018 е№ҙзҡ„ 1600 дәҝзҫҺе…ғеўһй•ҝеҲ° 2024 е№ҙзҡ„ 2695 дәҝзҫҺе…ғпјҢеӨҚеҗҲе№ҙеўһй•ҝзҺҮдёә 9.08%гҖӮ

иө„ж–ҷжқҘжәҗпјҡ еёӮеңәе’ҢеёӮеңә

жЎҲдҫӢз ”з©¶.

Case Study

Cloud Approach Increases Productivity, Lowers TCO

Renesas Electronics America (REA)'s on-premises, legacy integration system required a manual process of custom coding by an on-site expert and was costly and complicated. REA needed to replace the existing system. In addition, due to relocation, REA wanted to move the data center to the cloud.

Case Study

Connecting Cows to Save the Lives of Calves with MooCall

The idea for the Moocall calving sensor came about when one of the Moocall founding team, Niall Austin lost a heifer and her calf due to a difficult calving back in 2010. He had a theory that a device to measure tail movement might be able to predict the onset of calving and brought the idea to the other Moocall founders Michael Stanley and Emmet Savage. After many months of research and development the MooCall device was born, however they needed robust and reliable, global connectivity with roaming capability to ensure that this critical data could be transferred the crucial moment. Vodafone IoT worked closely with MooCall to implement a solution that works seamlessly every time, wherever the cow might be situated.

Case Study

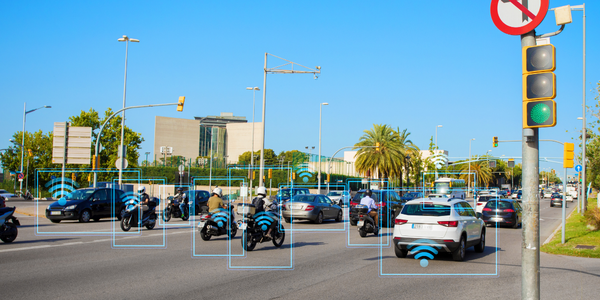

Vehicle to Everything

Connectivity is empowering more intelligent interactions between consumers and companies. An innovative automaker wanted to design and build a working prototype of a connected vehicle platform to accelerate speed to market and help the company understand today's connected world.