Case Studies.

Our Case Study database tracks 18,926 case studies in the global enterprise technology ecosystem.

Filters allow you to explore case studies quickly and efficiently.

-

(5,794)

- (2,602)

- (1,765)

- (764)

- View all

-

(5,073)

- (2,519)

- (1,260)

- (761)

- View all

-

(4,407)

- (1,774)

- (1,292)

- (480)

- View all

-

(4,157)

- (2,048)

- (1,256)

- (926)

- View all

-

(2,488)

- (1,262)

- (472)

- (342)

- View all

- View all 15 Technologies

- (1,732)

- (1,626)

- (1,605)

- (1,460)

- (1,423)

- View all 42 Industries

- (5,781)

- (4,113)

- (3,091)

- (2,780)

- (2,671)

- View all 13 Functional Areas

- (2,568)

- (2,482)

- (1,866)

- (1,561)

- (1,537)

- View all 127 Use Cases

- (10,333)

- (3,499)

- (3,391)

- (2,981)

- (2,593)

- View all 9 Services

- (503)

- (432)

- (382)

- (301)

- (246)

- View all 737 Suppliers

Selected Filters

18,926 case studies

|

Saving Water with Smart Management and Efficient Systems

Libelium

Water and electrical supply are two of the main concerns for public authorities. The demand of these resources grow as fast as the population in urban areas so they would become scarcer with the pass of the years. A Technavio report states that the use of smart water management technologies such as Big Data, sensoring and monitoring in real-time can help save more than USD 12 billion revenues for utilities annually.

|

|

The Power of Balancing Technology

Eurotech

Accurate balancing of the turbochargers used in cars and commercial vehicles is vital to ensure engine efficiency and longevity and it is carried out in both the manufacturing and remanufacturing of these units. If not measured and corrected through the balancing process, turbochargers will be noisy and in severe cases bearing failure can occur.

|

|

The Municipality of Orford Use eWON for Water Supply

HMS Networks

Orford, Quebec is home to 3,600 people. The rugged hills surrounding the town complicate the job of supplying water to its residents, businesses and fire protection services.

|

|

Sparks Dynamics Assists Atlas Container Secure a $15,000 BGE Energy Rebate

Sparks Dynamics

The ReMASTER Compressed Air Monitoring system was installed in 2015. This system is capable of monitoring compressed air system parameters on a continuous basis and transferring that information to a cloud server which can be accessed by Atlas Container personnel, Industrial Diagnostics and Sparks Dynamics. This information was collected into a database which can be exported to an Excel spreadsheet or displayed graphically using Sparks Dynamics ViewMaster Software. The average annual compressed air electricity expense was estimated to be approximately $116,000. This is based on an incremental $/KWh electric rate of $.091 per KWh and an estimated compressed air energy consumption of 1,279,200 KWH. The implementation phase of Energy Conservation Measures (ECMs) for the Compressed Air System included: • Identification and repair of compressed air leaks • Understanding of compressed air usage per manufacturing machine and installation of shut off valves when the machines are no longer in production mode • Identification of misapplications of compressed air to include blow offs, venturis, and cooling scenarios • Understand system pressure requirements and potential installation of point of use pressure regulation.

|

|

Grid of Tomorrow with National Grid UK

NI

The modern grid comes with new engineering challenges. In the United Kingdom, as renewable energy resources are being used to supplement fossil fuel production, power quality issues are surfacing. Combine this with the rapidly increasing demand for energy and the decommissioning of fossil fuel plants, and grid operators are finding that traditional measurement systems do not offer adequate coverage to handle these new challenges and manage the new risks the industry faces.

|

|

Product Development for Power Line Communication (PLC/BPL) Systems

Prodapt

The client wanted to develop a product that can acquire data from their meter units installed at the consumer's premises. A system capable of acquiring, transferring and archiving the data had to be in place, replacing the existing traditional method which was error prone and expensive to operate. The system needed to be integrated with the existing Customer Relationship Management (CRM) system for increasing the operational efficiency.

|

|

Unite Set For 10% Energy Reduction Thanks To Eseye Shoebill

Eseye

Unite Students needed to find out where and when the most energy was being expended, so they could better devise strategies to reduce energy consumption. Key to this plan was a monitor that wasn’t intrusive to the business or the residents and that didn’t require releasing staff to take meter readings.

|

|

IIoT retrofit to Ash Handling System for Thermal Power Plants | KPCL | INDIA

CONSYST

In India, 70 percent of the electricity generated is from coal based thermal plants. Indian coal is of low grade with ash content of the order of 30-45 % in comparison to imported coals which have low ash content of the order of 10-15%. 75 percent of this coal would go to thermal power plants and large quantities of fly ash, a residue of burning of pulverized coal and lignite is, thus being generated at Power Stations in the country, which not only requires large areas of precious land for its disposal but is also one of the sources of pollution of both air and water. The management of fly ash has been troublesome in view of its disposal.

|

|

Grabit Case Study

Flextronic

Grabit, a promising startup, wanted to take its revolutionary electroadhesion gripping technology to market. Flex Lab IX partnered with Grabit to perform state-of-the-art testing and make business connections that would help the company fundamentally change factory and warehouse automation. Today's factories and warehouses need automation technologies that can handle fragile electronics such as flat-screen TVs and solar panels. Grabit invented a new technology that could revolutionize factory and warehouse automation. But this groundbreaking technology had to undergo rigorous testing before it could launch.

|

|

Coor Brings IoT to the Office

Intel

Coor wanted an IoT solution to simplify office manager's job. The solution must require the following features: boost productivity, apply technology innovation, and consolidate management.

|

|

IIC Asset Efficiency Testbed

Infosys

A recent study on maturity of Asset Efficiency from Infosys and the Institute for Industrial Management (FIR) at Aachen University revealed that 85 percent of manufacturing companies globally are aware of asset efficiency, but only 15 percent have implemented it at a systematic level. Current challenges include lack of instrumentation of the assets, missing real-time data analytics, lack of context due to missing information from other systems, and lack of a holistic focus with other aspects of efficiency like energy, utilization, operations, and serviceability.GOALTo collect asset information efficiently and accurately in real-time and run analytics to make the right decisions

|

|

Using Real-time Intelligence to Solve Transportation Issues

Aeris

Isotrak knows that the demands placed on delivery fleets are constantly evolving and customers require greater insight into fleet operations so it uses business intelligence data to provide retailers and manufacturers with a total vision of their transportation ecosystem. Expanding the capabilities of its real-time ATMSi fleet management system, Isotrak provides integrated supply chain solutions that access real-time data with robust alerting and reporting capabilities.With 25% of the world’s top food retailers using Isotrak products, Isotrak required quicker access to analytics for its IoT/M2M deployments – delivered with reliable reporting methods and at a low total cost of ownership.

|

|

French grocery chain halves inventory processing time

Microsoft

Chronodrive is a drive-through grocery service in France: customers shop online and drive to neighborhood pickup points where their purchases are loaded into their cars. With more than 60 grocery stores in France, two in Italy, and more on the way, Chronodrive needs up-to-the-minute knowledge of what’s selling in each store so that it can order the right inventory for the next day. To stay agile, competitive, and operationally lean in a highly competitive and fast-growing market, Chronodrive migrated its entire on-premises datacenter to the cloud in late 2014, with most workloads moving to Microsoft Azure. Azure is a public cloud environment that provides compute, storage, networking, and other services for creating and hosting applications in Microsoft datacenters.

|

|

Data meets nature: One of the greenest data centers

Schneider Electric

Green Mountain is consuming data at an unprecedented pace: 3 billion Facebook videos viewed daily; 300 hours of video uploaded to YouTube every hour. In today’s data-driven world, the uptime of colocation data centers – vast banks of servers that process everything from online videos to financial assets – is essential. Delivering secure and reliable data center services can come at an environmental cost though: energy use in data centers today contributes to 2% of global CO2 emissions. They want one colocation facility, built in a former NATO bunker buried deep within a mountain, turn the tables and use the power of nature to become one of the world’s most reliable and sustainable data centers.

|

|

IIC - Water Management Testbed

Infosys

The growing water shortage is regarded as the most crucial global challenge, affecting both developing and developed nations at present. Large amount of water is lost in between the point of production and receipt by end users due to leaky pipes and outdated infrastructure. This results in the loss of millions of dollars and huge wastage of such a key resource. GOAL A substantial opportunity exists to reduce the amount of water lost. As water can be lost at multiple points over a wide geographical area, Internet of Things (IoT) technology is particularly well suited to address this problem. The Smart Water Management Testbed will implement a network of real-time sensors (leakage, moisture, and water -flow detection). These will be deployed at high-risk locations across the testbed water infrastructure to reduce the amount of water being ‘lost’ by: • Rapid detection of leaks • Preemptive detection of potential leaks • Precision irrigation of watered areas

|

|

Algae Lab Systems Case Study

B-SCADA

Algae Lab Systems contacted B-Scada when a customer of theirs was looking for a way to aggregate data from several hundred AlgaeConnect™ systems, each with several photobioreactors/ponds, in a single system. The AlgaeConnect™ system allows for monitoring and controlling of the equipment in clusters of reactors, as well as logging and graphing data, along with some other functions, but still lacked the ability to integrate the data from multiple AlgaeConnect™ deployments through a single interface with the custom graphics they desired. Therefore, the customer wanted a centralized interface through which to access their data, and they wanted it to be composed of graphics they chose.

|

|

Expertech - Capital Tool Inventory

BlackBerry

Costly tools used to splice fiber optic cables are an important part of Expertech’s operational and capitalized expenses, but the company did not have an automated system in place to track their tools and optimize their usage. The existing data in its tracking system was inaccurate and required manual updating, making it essential for the company to implement an efficient process to track and follow up on its capital tool inventory.

|

|

Ursalink Secures Internet Connection on Remote Monitoring for PLCs

Ursalink Technology

Staff working in the office needs access to industrial production management in remote fieldsNeed a fast and secure network that would provide the speed and reliability to underpin their time-critical operations

|

|

IIC Factory Operations Visibility & Intelligence Testbed

Fujitsu

Contextual and background data is often buried and in various formats; Storage and distribution of large amounts of raw data requires considerable compute resources and infrastructure; The cost of installation and maintenance of new computers, servers, and network equipment to collect and distribute data needs to be minimized. GOAL Establish new open environments for future factory operation visualization scenarios, with data upload and simulation capability to augment physical factory equipment; Provide a cloud-based platform that can combine factory sensor and operational data to enhance the visibility and analysis of key manufacturing processes, thereby enabling improvement of operational efficiency.

|

|

Excellence in Medical Diagnostics Powered by CodeMeter

WIBU-SYSTEMS

The custo med medical platform's diagnostic function consists of different software packages and devices in order to acquire the ECG, blood pressure profiles, and lung function data from patients. The products are integrated in clinical IT networks and need therefore to offer full modularity and scalability in terms of performance and usability. Furthermore, medical regulations require the after sales traceability and a protection against technological manipulation of the products.

|

|

LUMO Energy Optimizes Revenue and Operations

Splunk

LUMO Energy has considerable operational experience in the peak generation sector of the National Electricity Market in Australia. The energy provider wanted to extend the capacity of its SCADA system in order to enhance its ability to react to price fluctuations in real time and to maximize revenue. In addition, with the goal of increasing cost savings and operational efficiency, LUMO Energy was looking for a solution that would give real-time visibility into the infrastructure of its many power stations.

|

|

Data Warehouse to Reduce Maintenance Costs for Car Rental Company

Informatica

Europcar needed to: implement a holistic enterprise-wide decision support system: integrate data from sources across Europe, and ensure data quality and consistency.

|

|

Case Study: Trident Network

Fusion Connect

Trident Network is a fast growing mid-market company that designs equipment and components that enable commercial & industrial customers to remotely sub-meterwater, electric or gas consumption. Sub-metering allows for monitoring of resource usage on any circuit or pipe inside a facility, creating granular information about resource usage. The key to their new product line is the MeterReader™, which overlays existing OEM meter technology installed in commercial facilities across North America, allowing management of older technology as well as leveraging newerTrident Network sub-metering products.

|

|

Building a safer, smarter society with self-powered industrial IoT solutions

Dell Technologies

To fuel growth and innovation, V5 Systems needed to increase market exposure and evolve its intelligent security platform to support more use cases, requirements and technologies.

|

|

ASD Healthcare Delivers True Connected Care

Vodafone

ASD Healthcare’s Cubixx connected refrigeration solution was initially aimed at larger hospitals and pharmacies, utilising Wi-Fi or local area networks (LAN) for connectivity. With phase two, Cubixx would be rolled out to smaller practices and patients homes. The issue for ASD Healthcare was finding a single connectivity provider to cover the entire U.S., and facilitate international expansion.

|

|

Version Control for Systems and Machine Production

AUVESY-MDT

With the flood of data and numerous versions of software in the production environment of a firm, much time and effort is spent by workers searching, guessing or asking questions in order to solve issues.

|

|

Setting a New Pace for Increased Competitive Advantage

Software AG

Fujitsu needed a solution that would provide greater flexibility for user interfaces, facilitate improvements in its 24/7 support, enable faster on-boarding of customers and increase cost efficiencies. Fujitsu also needed continuous availability throughout the transition process due to demanding Service Level Agreements (SLAs) and high penalties.

|

|

MachineMetrics Helped Carlson Products to Increase Efficiency by over 20%

MachineMetrics

There’s always a sort of lag in the information we get from the ERP. It’s not real time, its not updated every second. We were able to see what happened yesterday, what happened last week but not what was happening right now, and we would always have to somehow fill that gap. Also, to get data into the ERP we were relying on a human being to accurately define and manually input the information to enter it into our database. All of the real-time monitoring systems that Carlson Products had seen were only dedicated to machining. They had chats with some of their equipment providers and the solutions they attempted to provide them with were not visually appealing, not web-based and felt quite rudimentary. They did attempt to do manual tracking before MachineMetrics, and they got so much junk data that they just stopped trying. They kept a Microsoft access database where employees would track this information themselves but with all the huge outliers, data it went to hell and a handbasket. The most important thing Carlson Products wanted was to look at was historical labor data information: whether or not the jobs were on target. Tracking down the supervisors and operators to understand why they weren’t on target was quite time consuming, not to mention most of their employees had difficulty remembering why problems had occurred when reviewing the issues reactively. There was no ability to identify systematic issues vs singular issues. Also, the lack of historical data made it difficult for them to calculate their utilization as well as their potential capacity.

|

|

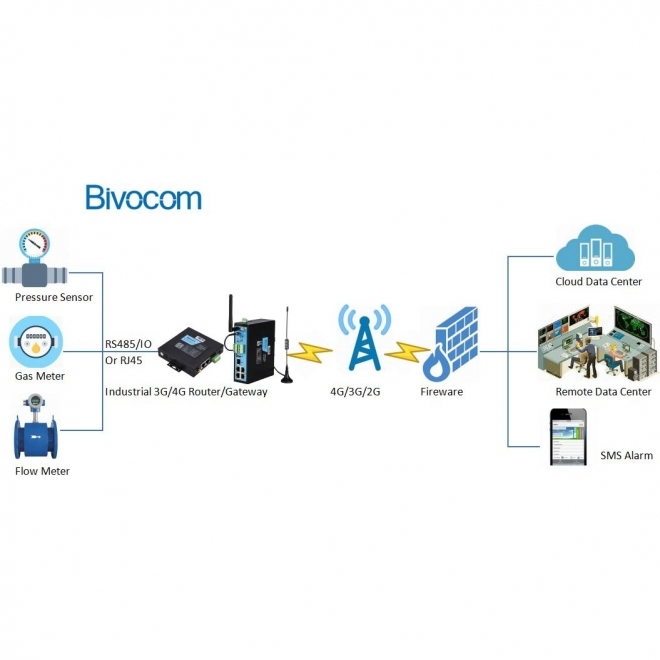

Bivocom Make Gas Metering/ Pipeline More Smarter

Bivocom Technologies

This gas remote monitoring solution is suitable for gas supply enterprises to monitor gas metering remotely. In the Monitoring Center, the gas dispatching personnel can monitor the gas supply situation of the whole city, direct the gas supply equipment scientifically, ensure the gas safety, also find and forecast the tube explosion accident in time. In addition, it also can expand the functions on gas leakage monitoring and valve remote control.

|

|

Reducing Unscheduled Downtime and Customer Efficiency

PTC

Leica Microsystems attributes its success to providing innovative products and superior customer service. To extend its leadership position, the company began exploring a more proactive service approach for its line of confocal microscopes and tissue processors. The Leica Microsystems project team began searching for a global software that would allow for the shift from a reactive to proactive service company. Their initiative focused on downtime avoidance and the prediction of potential problems across the globe, targeting issue prevention. As a result, customers would not only benefit from minimal product downtime, but from faster service and increased productivity. To obtain approval and funding for the initiative, the team would need to prove to management that this service strategy shift would result in optimized instrument uptime and reduced costs of service.

|