Case Studies.

Our Case Study database tracks 18,926 case studies in the global enterprise technology ecosystem.

Filters allow you to explore case studies quickly and efficiently.

-

(4)

- (3)

- (1)

- (1)

- View all

-

(4)

- (3)

- (1)

- (1)

-

(4)

- (3)

- (1)

-

(2)

- (2)

-

(2)

- (1)

- (1)

- View all 7 Technologies

- (1)

- (1)

- (1)

- (1)

- (1)

- View all 6 Industries

- (4)

- (2)

- (1)

- (1)

- (1)

- View all 5 Functional Areas

- (6)

- (1)

- (1)

- (1)

- (1)

- View all 6 Use Cases

- (2)

- (1)

- (1)

- (1)

- (1)

- View all 9 Suppliers

Selected Filters

11 case studies

|

DeviceLynk Delivers Customized IIoT Solution

ThingWorx

Previously to working with ThingWorx, DeviceLynk built an IIoT platform but found it lacked scalability. They needed something to capture and handle data from an unlimited amount of devices and customers.

|

|

IIC - Track and Trace Testbed

Bosch

Factory systems can detect - within a meter - the location of a tool; Misuse of tools can result in serious accident or injury; The production of many industrial and consumer goods requires exacting work - down to the precise force used to tighten a screw. GOAL Manage smart, hand-held tools in manufacturing, maintenance, and industrial environments

|

|

Automated Slab Tracking at ThyssenKrupp

S+P Samson

Steel slabs usually weigh between 20 to 40 tons each. After production, the surface is scaly and rusty. Outdoor storage and sea shipment expose the slabs to rough conditions. Loading ocean vessels is time consuming and total cost can easily exceed a few hundred thousand USD.RFID technology offers many benefits. RFID transponders are small, store the identity of the labelled product and enable readingout this data via antennas from a distance of several metres. However, there are special requirements for the use of RFID in thesteel sector. Firstly, the radio waves of the RFID readers are reflected by metal which creates major problems for reading out.And secondly, they must be attached securely as the heavy slabs weigh tons and can rub against each other during the transporton ships and trains, causing the labels to become detached or to be destroyed.

|

|

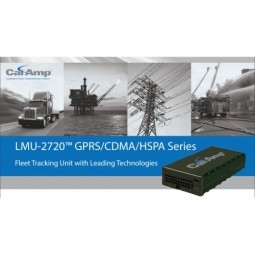

Remotely Control Industrial Spray Pump Maximize Efficiency

CalAmp

Graco industrial sprayer customers needed real-time data to maximize utilization of assets and crews, to deter unauthorized use of equipment, to keep equipment in top condition, and to provide more accurate job estimates and billing statements.

|

|

Xerafy's RFID Tags Track Dental Equipment

Xerafy

Columbia University's College of Dental Medicine (CDM) employs school-owned dental instrument in their training and needed a way to accurately track the instruments in order to contain costs and manage the sterilization process.

|

|

Expertech - Capital Tool Inventory

BlackBerry

Costly tools used to splice fiber optic cables are an important part of Expertech’s operational and capitalized expenses, but the company did not have an automated system in place to track their tools and optimize their usage. The existing data in its tracking system was inaccurate and required manual updating, making it essential for the company to implement an efficient process to track and follow up on its capital tool inventory.

|

|

Online Calculator Helps Haulers Increase Container Efficiency

Compology

As the waste industry continues to evolve and focus on more efficient and effective methods of tracking and deploying containers and other assets, were excited to be able to offer a solution for our customers.

|

|

Increased Range and Flexibility for Custodia Systems Customers

Vodafone

Custodia Systems is a security consultancy based in the UK. It was founded in 2005 by Peter Thompson, a former Goldman Sachs technology and engineering lead, with start up capital of £4,000 (approximately €4,800). It is now the global distributor of Appello tracking devices and its products currently protect £150 million (€180 million) of construction machinery in the UK.The Appello device is a small, portable unit (no bigger than a smartphone) with a battery life of up to two years. It has no external wiring and cannot be located by scanning devices used by professional thieves like GPS (Global Positioning System) units.The device is hidden, for example among the engineering of a piece of plant machinery and sends out a regular signal to mark its present location. Worldwide, Custodia Systems claims 80% of stolen equipment is recovered and back with its owners within eight hours.To ensure consumer confidence and provide a competitive advantage, Custodia Systems needed a fail-safe communications infrastructure that needed to be international, reliable and as accurate as possible. In addition, to support the launch of the AppelloGEO – a new product that can be used globally – Custodia Systems needed a global platform and fixed price international tariffs.

|

|

Kaazing Aims to Protect World Wide Assets Using DisasterAWARE Enterprise

Kaazing

Disaster management, for the past few decades, has taken an unreliable and hardly scalable approach to addressing significant natural catastrophes.

|

|

CAT M1 custom antenna for asset trackers

In the summer of 2018, Viatrax started a new LTE design project for their new GPS Tracker for LTE Cat 1M. Radientum was chosen to design the multiband antenna for the device. Despite the challenges, the product came out as a success.The GPS tracker itself was designed by an engineering company Device Solutions based in Morrisville, North Carolina. Device Solutions and Radientum worked closely in liaison to deliver Viatrax with the best possible result.When starting the project, Viatrax engineers were pondering whether they should locate the antenna on the circuit board itself or create a trace antenna. The latter was a better, but at the same time more difficult task.– Everyone agreed it was going to be a challenge. We discussed with the folks at Radientum and they said they guarantee it will work. If not, they wouldn’t have charged us for the work, Viatrax Automation CEO Mike Webster says.– Radientum went back and forth with our design people to make adjustments. It turned out they did a really good job and the trace antenna solution will end up saving us a lot of money and parts.

|

|

Fully Automated Identification for Alping Italia

S+P Samson

Full material traceability ensures process reliability in production and it is a major building block for the economic success of manufacturing companies. To optimise production management, automated identification systems with tags which have barcodes printed on them are now increasingly used in production facilities and warehouses. This ensures full control from the receipt of raw materials to the finishing of the products and shipping.The steel industry in particular, is a difficult environment and the labels and tags that ensure full material traceability have to withstand extreme conditions. Raw materials and products have rough surfaces. In addition, the data carriers are exposed to enormous heat and heavy soiling. And last but not least, the whole identification process always has to be carried out under time pressure.

|