Download PDF

Bakers Delight Boosts Monthly Export Goals by 30% with Brandfolder's Content Automation

Technology Category

- Analytics & Modeling - Natural Language Processing (NLP)

- Platform as a Service (PaaS) - Application Development Platforms

Applicable Functions

- Sales & Marketing

Use Cases

- Leasing Finance Automation

- Retail Store Automation

Services

- System Integration

The Challenge

Bakers Delight, Australia’s most successful bakery franchise, faced a significant challenge with their incumbent, print-oriented, local marketing production system. The existing platform was difficult to use, especially for vital POS elements like basket labels. It was impossible to extract data from the system to demonstrate ROI, and the platform did not support marketing channels like social and digital. The franchise network was requesting over 1,800 custom scope artworks annually from the corporate local marketing team, leading to high quantities of off-brand collateral. The local marketing team was spending all their time producing artwork instead of planning and operationalizing local marketing with individual franchisees to improve sales and community connection and awareness. The lack of data available from the incumbent system and the fast turnaround required for individual artwork requests made it difficult to forecast workload.

About The Customer

Bakers Delight is Australia’s most successful bakery franchise, with over 540 locations across Australia and New Zealand. As a family-owned business, Bakers Delight prides itself on supporting small local family businesses in providing their local communities with delicious and nutritious bread, freshly baked each and every day. The company faced challenges with their existing marketing production system, which was print-oriented and difficult to use. The system did not support digital marketing channels and made it difficult to extract data for ROI analysis.

The Solution

Bakers Delight needed a new local marketing solution that would improve user navigation and ease of use, increase flexibility for the types of collateral able to be created without compromising the brand, speed up artwork creation, and improve sentiment about, and use of local marketing. The solution came in the form of Brandfolder Content Automation. This technology offered templates that allowed franchisees to produce local marketing collateral easily and admins to quickly deliver new promotions. Brandfolder Content Automation empowered Bakers Delight franchisees to produce content, customize it to their store and community, and render their own marketing materials without branding concerns or bottlenecks.

Operational Impact

Quantitative Benefit

Related Case Studies.

Case Study

Digital Transformation in Insurance: A Case Study of Menora Mivtachim

Menora Mivtachim, one of Israel's largest pension fund and insurance carriers, was facing a significant challenge due to demographic trends in Israel. The growing rate of retirement planning and services was putting unprecedented pressure on the already strained insurance sector. The pension claims process was bottlenecked with complexities, bureaucracy, and errors. Menora Mivtachim's existing pension process was heavily manual and spreadsheet-based, requiring a team of 10 full-time employees to manage. The process involved gathering applicant information, conducting personal surveys, compiling bank information, and finalizing agreements. To leverage the growing opportunity in the retirement sector and position themselves as innovative insurtech leaders, Menora Mivtachim needed to digitalize their process, streamline the claims experience, and reduce quote times through automated processes.

Case Study

Automation in Mining: Unleashing Productivity and Efficiency with 5G

The mining industry, a significant contributor to global economic activity with revenues exceeding USD 500 billion, is facing a challenge of improving efficiency and profitability. The industry is gradually shifting its focus towards automation as the next area of opportunity. Boliden, one of the world's most successful mining companies, operates the Aitik mine, the largest open pit in Europe. The Aitik mine is expanding, and with the increase in production from 36 million metric tons of ore to 45 million metric tons, the amount of rock removed will also increase significantly. However, increasing the number of machines required for rock removal in a busy mine is not a straightforward task. Additionally, every blast creates toxic gases that need to dissipate before humans can enter the area and begin excavation. The challenge lies in improving efficiency, managing the increased production, and ensuring safety in the harsh mining environment.

Case Study

ANZ Bank's Digital Transformation with Nintex Advanced Workflow

ANZ Bank, one of the top 50 banks in the world and the fastest-growing bank in Indonesia, was facing a challenge with its rapidly increasing transaction volume. The bank's existing business processes and workflow were becoming overwhelmed. Like most banks in Indonesia, ANZ was manually handling document submission and verification. Customers filled out paper loan applications and supporting documents, then delivered them to bank branches by mail or courier. Branch officers traveled to the bank’s headquarters or used postal mail, email, and phone calls to submit loan documents for verification. Lost or inaccurate documents created more emails and phone calls. Additionally, ANZ had to adhere to strict verification and financial regulations, including the Foreign Accounts Compliance Act. This act requires that all banks outside the United States provide key information about U.S. clients, including citizenship validation, to the Internal Revenue Service–a complex yet crucial process.

Case Study

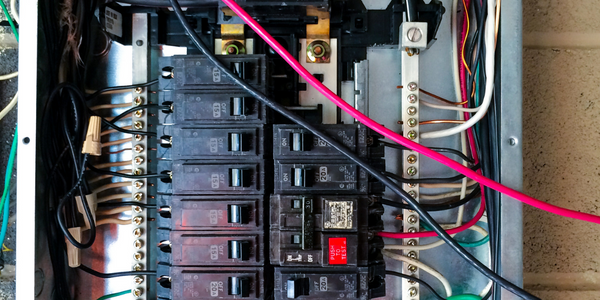

Streamlining Agricultural Automation with Eaton’s Package Solution

Grossi Electric, a full-service electrical contracting company, was tasked with facilitating the hulling, dehydrating, and preparation processes at a walnut processing plant in Waterford, California. The company aimed to explore innovative options for creating cleaner and more efficient control panels that would eliminate the intensive time, labor, and costs associated with excessive point-to-point wiring. As a rapidly growing electrical contracting company, Grossi Electric was also concerned about managing risk and cost while attempting to establish a new and unfamiliar service offering in a mature market for control products. The walnut processing plant presented a prime learning opportunity for the company to discover the best way to build more tailored control panels for its customers. The challenge was to enable a lean automation process that was smarter, simpler, more effective, and of unique advantage for clients.