Download PDF

Digital Twin Technology Reduces Waste and Enhances Efficiency in Automotive Manufacturing

Technology Category

- Analytics & Modeling - Machine Learning

- Sensors - Accelerometers

Applicable Industries

- Automotive

- Metals

Applicable Functions

- Product Research & Development

- Quality Assurance

Use Cases

- Digital Twin

- Manufacturing Process Simulation

Services

- Testing & Certification

The Challenge

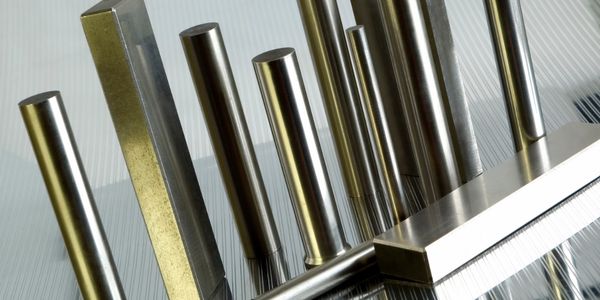

Patrone and Mongiello, a leading tier-one automotive supplier based in Italy, was seeking a solution to enhance the monitoring and control of its sheet metal forming process. The company aimed to improve product quality and reduce production waste. The solution needed to account for sheet metal properties such as stress, strain, and elasticity, and cover equipment operating conditions such as pad force and die friction. The challenge was to find a solution that could accurately simulate the company's existing sheet metal forming process, including machine press and sheet-metal behavior, system variables, and operating conditions.

About The Customer

Patrone and Mongiello is a leading tier-one automotive supplier based in Tito, Potenza, Italy. Founded in 1985, the company has seen consistent growth in its turnover and has invested in premier industrial technologies to support its automotive, agricultural, and general mechanical, cold-metal-forming manufacturing business. The company is committed to improving product quality and reducing production waste, and it sought a solution that could enhance the monitoring and control of its sheet metal forming process.

The Solution

Patrone and Mongiello selected Altair’s digital twin solution, implemented by Advanced Engineering (AE) Solutions, to meet their challenge. The solution involved creating a comprehensive digital twin that simulated the company’s existing sheet metal forming process. This included the machine press, sheet-metal behavior, system variables, and operating conditions. The digital twin used both simulated data and real data from accelerometers and AutoGrid sensors on the physical machine press. Altair produced the simulated data through finite element analysis (FEA) with Altair® Inspire™ Form. They also ran design-of-experiment (DoE) studies with Altair® HyperStudy® to reveal the effect of the sheet-metal properties and equipment-operation settings on the forming process performance. The team used Altair® romAI™ to create efficient reduced-order models (ROMs) that support AI and enable very fast simulation runtime. The ROMs revealed parameter variation effects on the forming process’s end-product quality. The team then used romAI to train machine learning models with simulated data. All data models were deployed through Altair® Panopticon™, a cloud-based dashboard where forming press operators could visually monitor actual sensor data against expected behavior for key performance indicators (KPIs) and deploy corrective actions throughout the sheet metal forming process.

Operational Impact

Quantitative Benefit

Related Case Studies.

Case Study

Goldcorp: Internet of Things Enables the Mine of the Future

Goldcorp is committed to responsible mining practices and maintaining maximum safety for its workers. At the same time, the firm is constantly exploring ways to improve the efficiency of its operations, extend the life of its assets, and control costs. Goldcorp needed technology that can maximize production efficiency by tracking all mining operations, keep employees safe with remote operations and monitoring of hazardous work areas and control production costs through better asset and site management.

Case Study

KSP Steel Decentralized Control Room

While on-site in Pavlodar, Kazakhstan, the DAQRI team of Business Development and Solutions Architecture personnel worked closely with KSP Steel’s production leadership to understand the steel production process, operational challenges, and worker pain points.

Case Study

Bluescope Steel on Path to Digitally Transform Operations and IT

Increasing competition and fluctuations in the construction market prompted BlueScope Steel to look toward digital transformation of its four businesses, including modern core applications and IT infrastructure. BlueScope needed to modernize its infrastructure and adopt new technologies to improve operations and supply chain efficiency while maintaining and updating an aging application portfolio.

Case Study

Integral Plant Maintenance

Mercedes-Benz and his partner GAZ chose Siemens to be its maintenance partner at a new engine plant in Yaroslavl, Russia. The new plant offers a capacity to manufacture diesel engines for the Russian market, for locally produced Sprinter Classic. In addition to engines for the local market, the Yaroslavl plant will also produce spare parts. Mercedes-Benz Russia and his partner needed a service partner in order to ensure the operation of these lines in a maintenance partnership arrangement. The challenges included coordinating the entire maintenance management operation, in particular inspections, corrective and predictive maintenance activities, and the optimizing spare parts management. Siemens developed a customized maintenance solution that includes all electronic and mechanical maintenance activities (Integral Plant Maintenance).

Case Study

RobotStudio Case Study: Benteler Automobiltechnik

Benteler has a small pipe business area for which they produce fuel lines and coolant lines made of aluminum for Porsche and other car manufacturers. One of the problems in production was that when Benteler added new products, production had too much downtime.