HMI Total Solution Enables Bus Manufacturers to Realize a Smart Factory

- Automation & Control - Human Machine Interface (HMI)

- Infrastructure as a Service (IaaS)

- Networks & Connectivity - Routers & Bridges

- Networks & Connectivity - WiFi

- Processors & Edge Intelligence - Embedded & Edge Computers

- Automotive

- Discrete Manufacturing

- Manufacturing System Automation

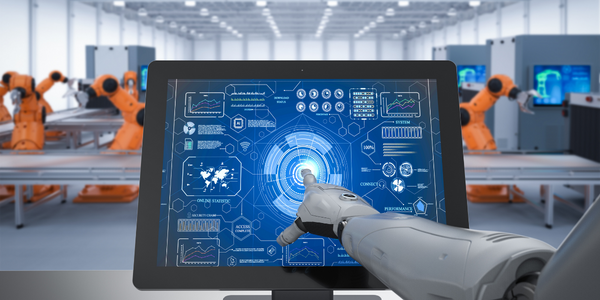

Industry 4.0 is gradually becoming a reality, and manufacturers are actively transforming their production process into intelligent manufacturing systems by leveraging Information Technology (IT) and Operations Technology (OT).

The main concept of Industry 4.0 is to realize transparent vertical and horizontal integration from the production line to management level so as to increase productivity and efficiency. In other words, the resources available throughout the entire production process must be digitalized and networked so that they can be visible and completely availability.

In order to improve the manufacturing process and carry out the transparent production control, the company planned to upgrade the existing manufacturing floor into the advanced and efficient factory. In addition to using MES as the production management system, it was also necessary to adopt panel PCs as the HMI and to establish a network communication in the manufacturing site.

On account of stability, the IT department of this company excluded commercial computers and decided to choose the industrial product which has the advantages of high-performance and low failure rates. The factory is a complex and harsh environment, so this project required providing different kinds of panel computers with rugged features for different machine uses, offering wired and wireless network devices to create a complete communication link, and the related modules to acquire peripheral data.

Therefore, to ensure this stability, the system integrator used industrial grade wireless devices with wider network coverage and higher power output.

Related Case Studies.