Download PDF

How Advantech’s Solutions for Yeefung’s Automated Guided Vehicles Help Turn Traditional Factories into Smart Factories

Technology Category

- Automation & Control - Automation & Process Control Systems

- Robots - Autonomous Guided Vehicles (AGV)

Applicable Functions

- Discrete Manufacturing

- Warehouse & Inventory Management

Use Cases

- Factory Operations Visibility & Intelligence

- Manufacturing System Automation

- Warehouse Automation

Services

- System Integration

- Software Design & Engineering Services

The Challenge

Yeefung Robotics Technology, a leading provider of comprehensive Automated Guided Vehicles (AGVs) and revolutionary parking solutions in China, was seeking comprehensive hardware and AGV controller solutions. The company wanted to leverage the benefits of Industry 4.0 to ensure that robotics and AGVs work at maximum efficiency with virtually no downtime, leading to reduced costs and increased profits. However, to ensure comprehensive monitoring and flexibility, smart factory AGVs must perform multiple arithmetic operations at speeds that traditional programmable logic controllers (PLCs) simply cannot handle.

About The Customer

Shenzhen Yeefung Robotics Technology, founded in 2014, is a leading provider of comprehensive Automated Guided Vehicles (AGVs) and revolutionary parking solutions in China. The company develops cutting-edge AGV systems featuring Advantech’s wireless AGV solutions. In combination with evolving technologies, such as sensors, wireless networks, and laser-based navigation, Yeefung has expanded the versatility of its AGV systems for use both in smart factories and smart parking. These solutions have proven to be more than just basic automation tools, providing comprehensive monitoring and flexibility for smart factory AGVs.

The Solution

Advantech provided Yeefung with a range of solutions, including its wireless AGV solutions and the PC-based UNO2272G embedded automation computer. The UNO-2272G, equipped with an Intel® Atom™ J1900 processor, wireless communication module (PCM-24S2WF), and CANbus module (PCM26D2CA), can receive commands from a central dispatch system and quickly process the data collected from an AGV’s anti-collision sensors, 360-degree laser transmitter, and magnetic nail scanner to rapidly calculate the AGV’s parking location and travel path. Other Advantech solutions used include the EKI7710E-2C managed Ethernet switch, WISE-5121 Wi-Fi AP/Client, and FPM-7061T VGA industrial monitor. These solutions allow Yeefung to produce state-of-the-art AGV systems featuring a wide range of smart factory capabilities, such as instruction issuing, travel track and position monitoring, system health diagnosis, and automatic scheduling.

Operational Impact

Quantitative Benefit

Related Case Studies.

Case Study

Plastic Spoons Case study: Injection Moulding

In order to meet customer expectations by supplying a wide variety of packaging units, from 36 to 1000 spoons per package, a new production and packaging line needed to be built. DeSter wanted to achieve higher production capacity, lower cycle time and a high degree of operator friendliness with this new production line.

Case Study

Robot Saves Money and Time for US Custom Molding Company

Injection Technology (Itech) is a custom molder for a variety of clients that require precision plastic parts for such products as electric meter covers, dental appliance cases and spools. With 95 employees operating 23 molding machines in a 30,000 square foot plant, Itech wanted to reduce man hours and increase efficiency.

Case Study

Fully Automated Visual Inspection System

Tofflon has developed a fully automatic machine that uses light to inspect vials, medicine bottles, or infusion containers for glass fragments, aluminum particles, rubber grains, hairs, fibers, or other contaminants. It also detects damaged containers with cracks or inclusions (microscopic imperfections), automatically removing faulty or contaminated products. In order to cover all production processes for freeze-dried pharmaceuticals, Tofflon needed to create an open, consistent, and module-based automation concept.

Case Study

IoT Solution for Cold Chain

Most of the customer's warehouses run on utility and generator power. Since these warehouses are in remote locations, power outages are a very common scenario. Diesel fuel, thereby, becomes a significant cost for these warehouses. Energy consumption was also very high due to the lack of a consistent temperature throughout the facility. This lack of a consistent temperature in all areas and no way to control it, resulted in the customer losing a significant amount of their temperature sensitive goods due to spoilage.

Case Study

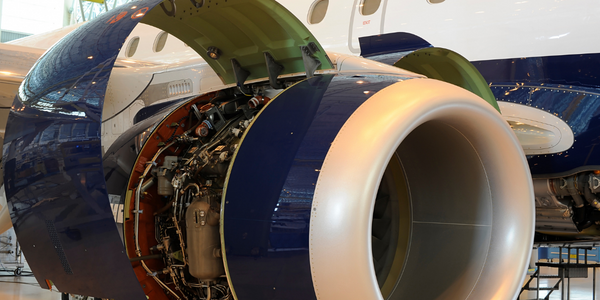

Accelerate Production for Spirit AeroSystems

The manufacture and assembly of massive fuselage assemblies and other large structures generates a river of data. In fact, the bill of materials for a single fuselage alone can be millions of rows of data. In-house production processes and testing, as well as other manufacturers and customers created data flows that overwhelmed previous processes and information systems. Spirit’s customer base had grown substantially since their 2005 divestiture from Boeing, resulting in a $41 billion backlog of orders to fill. To address this backlog, meet increased customer demands and minimize additional capital investment, the company needed a way to improve throughput in the existing operational footprint. Spirit had a requirement from customers to increase fuselage production by 30%. To accomplish this goal, Spirit needed real-time information on its value chain and workflow. However, the two terabytes of data being pulled from their SAP ECC was unmanageable and overloaded their business warehouse. It had become time-consuming and difficult to pull aggregate data, disaggregate it for the needed information and then reassemble to create a report. During the 6-8 hours it took to build a report, another work shift (they run three per day) would have already taken place, thus the report content was out-of-date before it was ever delivered. As a result, supervisors often had to rely on manual efforts to provide charts, reports and analysis.

Case Study

SAP Leonardo Enabling Rocket Science

At times, ULA has as many as 15 different operating systems dedicated to overlapping processes, such as rocket design, testing, and launch. Multiple systems created unnecessary costs and unwanted confusion among workers at offices, factories, and launch sites in different location. In order to improve collaboration and transparency during vital activities that directly influence mission success, ULA wanted to improve data sharing and streamline manufacturing processes.