Improved Monitoring in Industrial Manufacturing Facility

- Functional Applications - Remote Monitoring & Control Systems

- Infrastructure as a Service (IaaS)

- Networks & Connectivity - Gateways

- Networks & Connectivity - RF Transceivers

- Networks & Connectivity - RFID

- Mining

- Maintenance

- Remote Asset Management

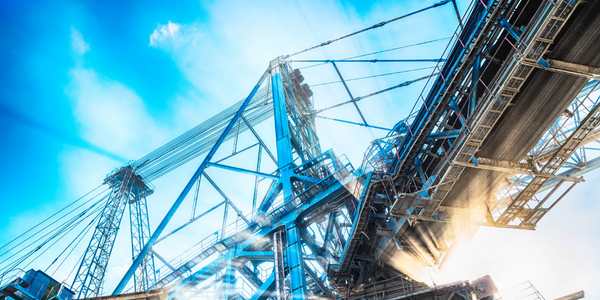

When your crane is moving tons of magma-hot iron, you can’t afford an unexpected failure. McWane Ductile knew monitoring the crane motor metrics within their facility could help prevent a mechanical failure that would strand an enormous bucket of molten metal overhead. Unfortunately, their legacy wired monitoring system couldn’t work with moving objects in this extreme environment. If they could integrate wireless capabilities into their existing equipment they could extend their monitoring capabilities without starting over from scratch.

SNAP-based RF Modules and IoT Gateways were the perfect solution for McWane Ductile. McWane incorporated the modules into the monitoring sensors, eliminating the need to wires—meaning that the RF modules acted as a drop-in replacement for cabling. With SNAP OS on the modules, no complicated work had to be done to configure the RF data routing. The SNAP OS determined how to send data through the mesh network formed by the modules. The sensor data is funneled through a SNAP IoT Gateway to a computer for easy monitoring. And with modules, gateway, and computer connecting directly on their own network—no internet connection to the outside world is required. This is a huge deal for manufacturers that prefer to keep their equipment from being connected to the internet for fear of malicious hacking attempts.

Related Case Studies.