Joy Mining Systems

- Functional Applications - Remote Monitoring & Control Systems

- Mining

- Process Manufacturing

- Process Control & Optimization

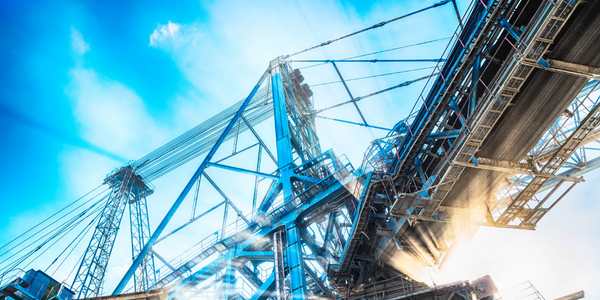

Joy equipment faces many challenges. The first is machine integration and control. The business end of the machine has a rapidly-spinning cylinder with 6-inch diamond-studded cutting teeth. It chews through rock at rates measured in tens of tons per minute. The system grinds through the rock in front, creating a rectangular mine tunnel. Hydraulic lifters support the ceiling as the machine moves forward. Automated drills and screws drive 3-ft long screws into the ceiling to stabilize it. The rock and coal fall into a set of gathering "fingers" below the cutting cylinder. These fingers scoop up the rock and coal and deposit it onto a conveyor belt. The conveyor passes under the machine and out the back. A train of conveyor belt cars, up to a mile long, follows the cutter into the mine. The rock shoots along this train at over 400 feet per minute until it empties into rail cars at the end. Current systems place an operator cage next to the cutter. Choking dust (potentially explosive), the risk of collapse and the proximity of metal and rock mayhem make the operator cage a hazardous location.

The new 14CM Continuous Miner system uses Connext DDS. Intelligent control algorithms optimize cutter pressure and rate, follow the coal seam, ensure floor and ceiling levels and enforce machine limits to reduce failures. The operator can be moved back to a safe distance from the action. Connext DDS provides fast data availability from all the working parts of the machine to a local feedback controller. Connext DDS also delivers data up the mine to allow surface monitoring. In the future, it will integrate machine control all the way to cloud-based analysis and production monitoring systems. Software Components - Connext DDS software

Related Case Studies.