Integrating vision into a manual assembly process

- Analytics & Modeling - Computer Vision Software

- Automotive

- Discrete Manufacturing

- Computer Vision

- Software Design & Engineering Services

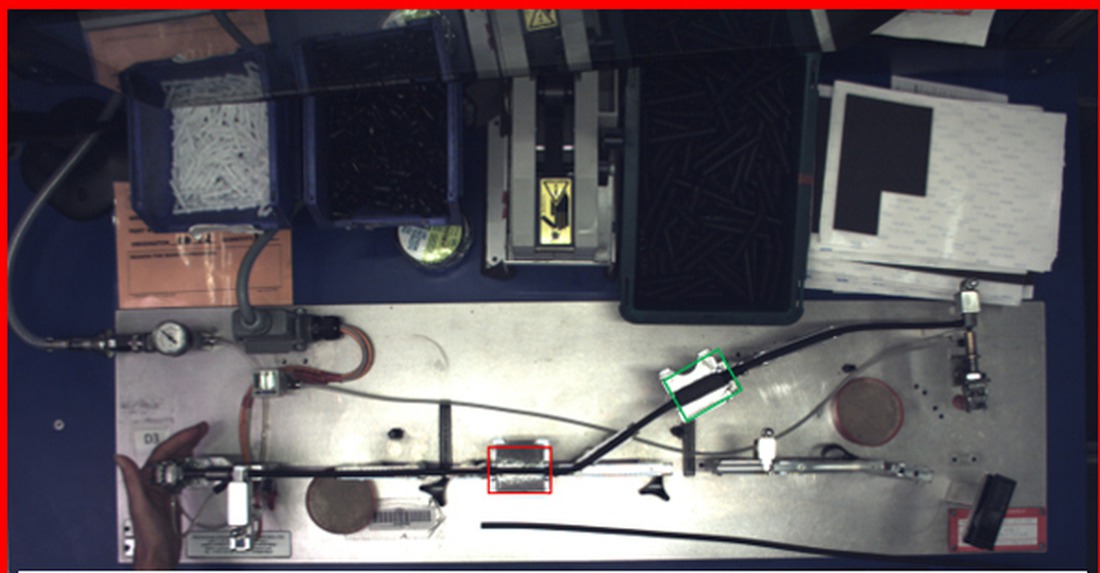

Quality defect analysis indicated that many of the defects associated with manual assembly could be identified using industrial vision. Each variant requires a dedicated manufacturing fixture which can be used on any of 80 assembly workbenches.

- Once the tubing is locked into the fixture, operators assemble the product from printed assembly documentation which include written instructions, diagrams and pictures.

- On completion, the assembly is visually inspected and compressed air is forced through the tube to ensure that there are no blockages.

- When testing is passed, the completed part is released and production data is sent to the company’s OEE system.

While it was clear that adding a vision system could identify defects, the company’s Advanced Manufacturing Team realised that a much more complete solution was to fully integrate the vision system as part of the assembly process in order to:

- Utilise the manufacturing SQL database

- Ensure that only appropriately trained operators can work on a particular assembly

- Ensure that the correct fixture is being used for a batch

- Provide complete traceability for individual assemblies

- Provide the flexibility to adapt the system for any new or modified variants

- Reduce the amount of paperwork involved in the assembly process

This improves the efficiency of the assembly process and reduces costs associated with waste and rejected products.

Kautex

Kautex is a top 100 Tier 1 supplier to global automotive OEMs.

The vision solution was developed by STEMMER IMAGING in conjunction with Envisage Systems Ltd, a systems integrator with whom they had worked closely previously and who took the lead on this project.

- A 5 Mpixel Genie Nano GigE Vision colour camera equipped with a 1” format, 12 mm focal length lens is mounted above a workbench. This provides a 1.3 metre field of view.

- Bar lights from Smart Vision Lights provide the illumination, overcoming any effects from ambient light coming through skylights in the assembly area.

- A GEVA-300 compact vision processor, running Sherlock machine vision software provides local image evaluation before images are transferred to the central server via Ethernet. It can also accommodate additional cameras and so is upwardly scalable.

The system uses standard measurement and inspection tools from Sherlock, for identifying the presence of the correct coloured tape in the correct position, measurements on foam pads and clips etc.

The camera, vision processor and software are all Teledyne DALSA products. Envisage also designed a bespoke operator interface for the software. STEMMER IMAGING supplied all of the imaging components used as well as providing places for Kautex personnel on a training course for the Sherlock software.

Demonstration systems were also made available for proof of process through the early parts of the project. Twenty of the 80 workbenches were fitted with a vision system, all connected to the company’s central server via Ethernet.

Related Case Studies.