Remote Wellhead Monitoring

- Networks & Connectivity - Cellular

- Networks & Connectivity - Ethernet

- Networks & Connectivity - Gateways

- Networks & Connectivity - Routers & Bridges

- Processors & Edge Intelligence - Embedded & Edge Computers

- Sensors - Camera / Video Systems

- Sensors - Flow Meters

- Sensors - Level Sensors

- Sensors - Liquid Detection Sensors

- Sensors - Pressure Sensors

- Sensors - Temperature Sensors

- Oil & Gas

- Process Manufacturing

- Remote Asset Management

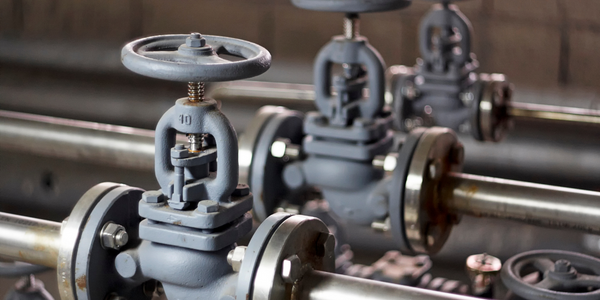

Each wellhead was equipped with various sensors and meters that needed to be monitored and controlled from a central HMI, often miles away from the assets in the field. Redundant solar and wind generators were installed at each wellhead to support the electrical needs of the pumpstations, temperature meters, cameras, and cellular modules. In addition to asset management and remote control capabilities, data logging for remote surveillance and alarm notifications was a key demand from the customer. Terra Ferma’s solution needed to be power efficient, reliable, and capable of supporting high-bandwidth data-feeds. They needed a multi-link cellular connection to a central server that sustained reliable and redundant monitoring and control of flow meters, temperature sensors, power supply, and event-logging; including video and image files. This open-standard network needed to interface with the existing SCADA and proprietary network management software.

Requiring full integration of SCADA with remote monitoring capabilities, Terra Ferma searched out Moxa to meet their networking demands. The decision was an easy one; Moxa’s vertically integrated oil and gas products provide a variety of end-to-end solutions that all feature strong certifications for harsh environments, low power consumption, and also the industry’s only UL Class 1, Division 2 IP video camera. Twenty wellhead applications link directly to a remote central server and control center, allowing for remote operations control, surveillance, and systems diagnostics from miles (or even continents) away. Field technicians and site managers are notified of critical wellhead events by SMS or email, and may access remote video feeds and sensor readings from the field using any web enabled smartphone, laptop, or tablet. The legacy SCADA is fully integrated with the customer’s industry standard flow meters, sensors and IP cameras over both wireless and serial links, allowing for detailed monitoring of site production. Detailed real-time overviews of injection, pipeline, or water and fracturing fluid processes are all available. At the control center, a central cellular modem receives feeds from a network of UL Class 1, Division 2 IP cameras, automatically storing event-driven images and video feed to the network server. Terra Ferma and Moxa, along with MSI Tec, are extending enterprise IT communications from the corporate offices out to the most remote and harsh industrial environments the oil and gas industries have to face. From in-the-field sensors at the very edge of the network all the way up to remote data acquisition and SCADA integration, Terra Ferma and Moxa are enabling the digital oil field across the globe, pushing industrialized Ethernet, wireless communications, embedded computing, and industrialized IP video out to the harshest extremes the industry has to offer.

Related Case Studies.