Refinery Saves Over $700,000 with Smart Wireless

- Networks & Connectivity - Gateways

- Sensors - Acoustic Sensors

- Sensors - Gas Sensors

- Oil & Gas

- Process Manufacturing

- Machine Condition Monitoring

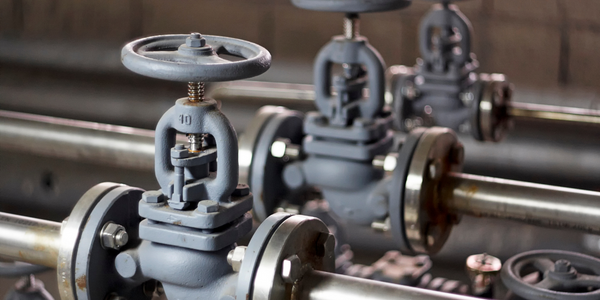

One of the largest petroleum refineries in the world is equipped to refine various types of crude oil and manufacture various grades of fuel from motor gasoline to Aviation Turbine Fuel. Due to wear and tear, eight hydrogen valves in each refinery were leaking, and each cost $1800 per ton of hydrogen vented. The plant also had leakage on nearly 30 flare control hydrocarbon valves. The refinery wanted a continuous, online monitoring system that could catch leaks early, minimize hydrogen and hydrocarbon production losses, and improve safety for maintenance.

Emerson installed 94 Wireless Acoustic Transmitters and 2 Wireless Gateways with one gateway and 47 transmitters in each refinery. 26 acoustic transmitters were installed upstream of the vent and flare valves. Total 22 transmitters were installed upstream of PRVs in the hydrogen unit. The alarms and health indications from the continuous online acoustic monitoring network enabled the refinery to initiate corrective actions when leakage occurred.

Related Case Studies.