下载PDF

Refinery Saves Over $700,000 with Smart Wireless

技术

- 网络与连接 - 网关

- 传感器 - 声学传感器

- 传感器 - 气体传感器

适用行业

- 石油和天然气

适用功能

- 流程制造

用例

- 机器状态监测

挑战

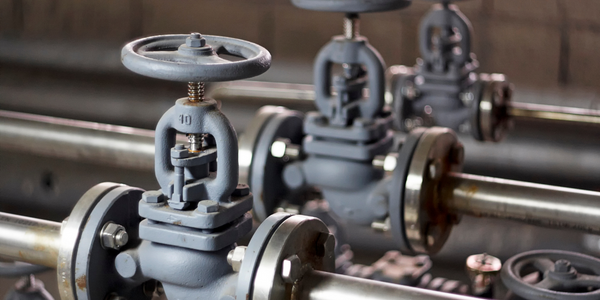

世界上最大的炼油厂之一具备精炼各种类型的原油和制造从车用汽油到航空涡轮燃料的各种等级的燃料的能力。由于磨损,每个炼油厂的八个氢气阀泄漏,每排放一吨氢气的成本为 1800 美元。该工厂的近 30 个火炬控制碳氢化合物阀门也有泄漏。该炼油厂需要一个连续的在线监控系统,能够及早发现泄漏,最大限度地减少氢气和碳氢化合物的生产损失,并提高维护的安全性。

客户

未公开

关于客户

世界上最大的炼油厂之一。

解决方案

艾默生在每个炼油厂安装了 94 个无线声波变送器和 2 个无线网关,其中一个网关和 47 个变送器。排气阀和火炬阀上游安装了 26 个声波变送器。在氢气装置的 PRV 上游安装了 22 个变送器。来自连续在线声学监测网络的警报和健康指示使炼油厂能够在发生泄漏时采取纠正措施。

收集的数据

Alarms For Automated Applications, Facility Health Status, Fault Detection, Leakage

运营影响

数量效益

相关案例.

Case Study

Taking Oil and Gas Exploration to the Next Level

DownUnder GeoSolutions (DUG) wanted to increase computing performance by 5 to 10 times to improve seismic processing. The solution must build on current architecture software investments without sacrificing existing software and scale computing without scaling IT infrastructure costs.

Case Study

Remote Wellhead Monitoring

Each wellhead was equipped with various sensors and meters that needed to be monitored and controlled from a central HMI, often miles away from the assets in the field. Redundant solar and wind generators were installed at each wellhead to support the electrical needs of the pumpstations, temperature meters, cameras, and cellular modules. In addition to asset management and remote control capabilities, data logging for remote surveillance and alarm notifications was a key demand from the customer. Terra Ferma’s solution needed to be power efficient, reliable, and capable of supporting high-bandwidth data-feeds. They needed a multi-link cellular connection to a central server that sustained reliable and redundant monitoring and control of flow meters, temperature sensors, power supply, and event-logging; including video and image files. This open-standard network needed to interface with the existing SCADA and proprietary network management software.

Case Study

H800L IoT Ball Valve

Ham-Let is a leading manufacturer of valves, fittings and instrumentation. One of the key challenges in this industry is identifying malfunctions and shutting off the appropriate valves before any damage can be done. However, it is often a demanding task to identify the cause of the malfunction and isolate the valves quickly.