Download PDF

Saving 70% of Operational Costs with Intelligent Process Automation at FRDC

Technology Category

- Application Infrastructure & Middleware - Event-Driven Application

Applicable Industries

- Life Sciences

Applicable Functions

- Product Research & Development

Use Cases

- Inventory Management

- Time Sensitive Networking

Services

- System Integration

The Challenge

The Fisheries Research and Development Corporation (FRDC) in Australia, a co-funded partnership between the Australian Government and the fishing industry, was facing a significant challenge with its funding application process. The process was managed by a bespoke tool built by a local software developer, which was not only slow but also prohibitively expensive for even minor changes. The FRDC, which plays a crucial role in the sustainability of Australia’s oceans, needed a more efficient and cost-effective way to manage and track the high number of research funding applications it received. The existing system was rigid and expensive, and the stakeholders were looking for an innovative and dynamic solution that would allow users to quickly make changes without excessive coding.

About The Customer

The Fisheries Research and Development Corporation (FRDC) is a co-funded partnership between the Australian Government and the fishing industry. It plays a significant role in the sustainability of Australia’s oceans, rich with wildlife. FRDC primarily administers research grants to enable data-driven decisions and strategic management of Australia’s natural resources. A significant portion of FRDC’s funding is directed at research that benefits the three sectors of the fishing industry: commercial (wild catch and aquaculture), recreational, and indigenous. The FRDC was in need of a more efficient and cost-effective way to manage and track the high number of research funding applications it received.

The Solution

FRDC chose Nintex K2 Five as their solution after considering several local and international options. Nintex K2 Five was selected for its built-in forms technology, low-code functionality, and its ability to integrate out-of-the-box with existing systems like SQL, SharePoint, and Microsoft CRM. FRDC used Nintex K2 Five to build an external user manager and an online portal that allowed candidates to better manage their own applications, thereby reducing the corporation's responsibility. The new system enabled FRDC to meet its six-month deadline for the entire process overhaul, a feat that a similar organization using different software was unable to achieve. The solution also provided opportunities for the internal team to make system modifications on their own timeline and at no outside cost.

Operational Impact

Quantitative Benefit

Related Case Studies.

Case Study

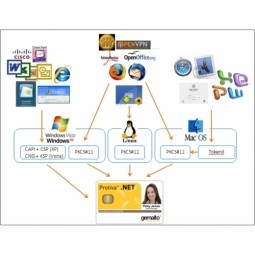

Corporate Identity Solution Adds Convenience to Beckman Coulter

Beckman Coulter wanted to implement a single factor solution for physical and remote logical access to corporate network. Bechman Coulter's users were carrying smart card badges for doors, but also needed a one-time password token to access to our corporate network when they were not in the office. They wanted to simplify the process.

Case Study

Embracing Business Success in Real Time

· Increase control over growing Big Data to improve business decisions · Manage data for 28,000 biotechnology stockkeeping units in the fields of microbiology, molecular biology, animal cell cultures, plant tissue cultures, and lab ware for laboratory chemicals · Accelerate report generation and analysis with real-time data

Case Study

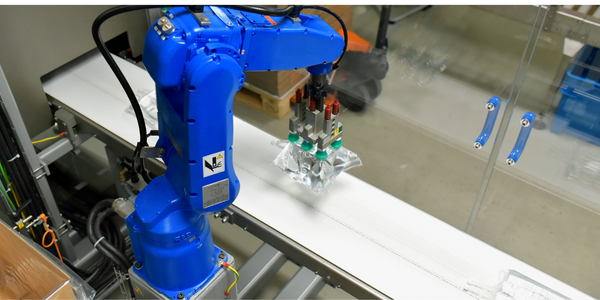

Flow Robotics: Scaling Up Production and Accelerating Product Development with IoT

Flow Robotics, a Danish manufacturer, developed flowbot™ ONE pipetting robots to alleviate the strain on bioanalysts in life-science laboratories and hospitals across Europe. These robots were designed to automate part of the testing process, speeding up the time it takes to produce results and reducing pressure on staff. However, the company faced challenges in scaling up production and accelerating product development. High workloads and physically challenging conditions have long been an issue for laboratory professionals. Flow Robotics estimates that around half of medical lab technicians carry out the same arm movements for at least a quarter of their working day. The American Society for Clinical Pathology reported that 85% of laboratory professionals feel burnt out; 36% struggle with inadequate staffing; and 32% face a heavy workload and pressure to complete all testing on time.

Case Study

Revolutionizing Aerospace Industry with 3D Printing: A 63% Lighter Titanium Part

GE Aviation, a renowned name in the aerospace industry, recognized the potential of 3D printing technology in transforming the sector. The primary challenge was to reduce the weight of the aerospace parts, which would directly impact the fuel costs. A lighter airplane would mean lower fuel consumption, leading to cost savings and a smaller carbon footprint. However, achieving this weight reduction without compromising the strength and functionality of the parts was a significant challenge. Traditional manufacturing methods were not able to provide the desired weight reduction while maintaining the required stiffness and strength of the parts. The challenge was to find a solution that could create strong, light, and functional aerospace parts.

Case Study

Material Intelligence at Ethicon: Sustaining Medical Device Manufacturability and Improving Patient Care

Ethicon, a world-class medical devices company, faced several challenges in its operations. The rapid selection of manufacturing materials compliant in global markets was critical to assure patients, practitioners, and purchasing organizations of the biocompatibility of their medical devices. Ensuring supply chain continuity and minimizing risks of obsolescence for medical devices due to regulatory changes were also crucial in meeting Ethicon’s ongoing commitment to maintaining patient care. Furthermore, the engineers at Ethicon were developing the next generation of medical devices and needed to access historical material data to accelerate new product development. The process of centralizing and digitalizing its materials information was a significant challenge that Ethicon needed to overcome.

Case Study

IWT's Transformation: Customizing with Efficiency in IoT

IWT, a company specializing in the design, manufacture, and installation of washing systems for the life sciences and pharmaceutical industries, faced a significant challenge in managing its wide product portfolio. The company manufactures 45 different models, 60% of which are customized to some degree. This high level of customization, combined with limited production quantities, necessitated a controlled process for managing the release of engineering changes. The goal was to achieve efficiency, reduce process time, and better coordinate production throughout the organization. The need for strict compliance in heavily regulated industries further complicated the situation. IWT's existing PLM journey with Dassault Systèmes’ SOLIDWORKS for 3D CAD and Enovia for managing CAD data and Bills of Materials (BOMs) was proving inadequate. The system had limited part classification, no workflow, and no tool to ensure data consistency. The management of non-CAD documents was also a challenge, with information often difficult to find and access.