Download PDF

Shandong Ruyi Meeting “Made in China 2025” head-on

Technology Category

- Functional Applications - Manufacturing Execution Systems (MES)

- Functional Applications - Product Lifecycle Management Systems (PLM)

Applicable Industries

- Apparel

Applicable Functions

- Process Manufacturing

- Quality Assurance

Use Cases

- Manufacturing System Automation

- Predictive Maintenance

- Process Control & Optimization

Services

- System Integration

- Software Design & Engineering Services

- Training

The Challenge

In 2015, the Chinese government unveiled “Made in China 2025”, a ten-year plan intended to transform China from a manufacturing giant into a world manufacturing power by upgrading its industry to smart technology and emphasizing superior product quality and brand image. The new initiative, coupled with Ruyi’s ambitious plans to expand its business into the US and Europe, meant the company needed to radically overhaul its approach to manufacturing so that it could run at peak efficiency, while producing impeccable-quality clothing that reflected the government’s new vision for what “Made in China” means. Always at the forefront of innovation, Ruyi was quick to embrace the Chinese government’s “Made in China 2025” guidelines, placing the plan’s cornerstone tenets of quality and efficiency at the top of its priority list. When the company decided to upgrade its Tai’an menswear factory with smart technology and automated processes, it turned to Lectra for help.

About The Customer

Founded in 1972, Chinese group Shandong Ruyi is a global leader in the textile and apparel industry, boasting annual revenues of more than RMB 48bn ($7bn), as well as one of the world’s largest industrial supply chains for wool and cotton processing. Its Tai’an plant, which specializes in manufacturing high-end menswear, turns out over a million suits a year. Ruyi is known for its commitment to innovation and quality, aligning with the Chinese government's “Made in China 2025” initiative to transform the manufacturing sector. The company is also expanding its footprint internationally, seeking partnerships with established companies in the US and Europe.

The Solution

Ruyi turned to Lectra for help transforming their Tai’an factory from a traditional garment plant into an Industry 4.0-ready production facility empowered by technology and smart manufacturing. After conducting a preliminary analysis of the plant’s existing workflow, Lectra consultants worked closely with the company to map out a transformation plan for the facility, laying out short- and long-term goals along the way, and looking at how international best practices could be applied to improve the company’s management and operations. With the help of Lectra’s experts, Ruyi began implementing leaner cutting methods at the Tai’an location, kickstarting productivity in its cutting room by adopting Lectra’s automated marker-making software and adding 6 new Vector cutters to the factory floor. The company began using Lectra’s automated marker-making software Diamino to speed up pre-production and installed six new high-speed Vector machines on the factory floor that would not only improve the quality of their finished product with more accurate cutting, but would also allow them to deliver to customers faster by improving overall efficiency and boosting productivity. During the transition, Lectra’s experts were on hand to offer advice and technical support.

Operational Impact

Quantitative Benefit

Related Case Studies.

Case Study

Fire Alarm System and Remote Monitoring Sytem

Fire alarm systems are essential in providing an early warning in the event of fire. They help to save lives and protect property whilst also fulfilling the needs of insurance companies and government departments.Fire alarm systems typically consist of several inter-linked components, such as smoke detectors, heat detector, carbon monoxide, manual call points, sounders, alarm and buzzer. The fire alarm system should give immediate information in order to prevent the fire spread and protect live and property.To get maximum protection a shoe manufacturer in Indonesia opted for a new fire alarm system to monitor 13 production sites spread over 160 hectars. Although the company had an existing fire alarm system, it could not be monitored remotely.It was essential that the new system would be able to be monitored from a central control room. It needed to be able to connect to the existing smoke detector and manual call point. Information should be easily collected and passed on to the Supervisory Control and Data Acquisition (SCADA) system. Furthermore, the system should have several features such as alarm management, auto reporting, being connected to many client computers without additional cost, and run 24/7 without fails. The company also needed a system which could be implemented without changing the architecture of the existing fire alarm system.

Case Study

IoT Applications and Upgrades in Textile Plant

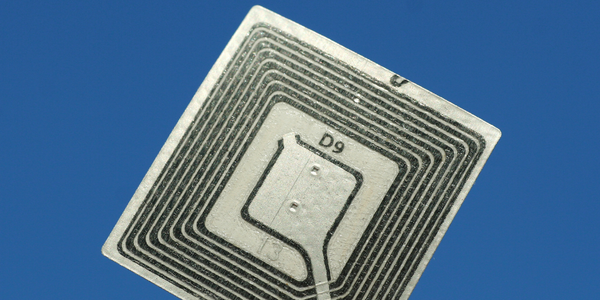

At any given time, the textile company’s manufacturing facility has up to 2,000 textile carts in use. These carts are pushed from room to room, carrying materials or semi-finished products. Previously, a paper with a hand-written description was attached to each cart. This traditional method of processing made product tracking extremely difficult. Additionally, making sure that every cart of materials or semi-finished products went to its correct processing work station was also a problem. Therefore, the company desired an intelligent solution for tracking assets at their factories. They also wanted a solution that would help them collect process data so they could improve their manufacturing efficiency.

Case Study

Retailer Uses RFID Scanner to Improve Efficiency

Patrizia Pepe wished to improve the logistics of their warehouse: accepting incoming goods from their production sites, movement of items throughout

the warehouse, and packaging of goods for distribution to the retail locations. They initially tried to use barcodes for this function. Because barcodes must be individually scanned within a line-of-sight, the acceptance of goods coming into the warehouse was too time consuming. Working with the University of Florence, Patrizia Pepe instituted a five-month pilot project beginning in August of 2009 to test the validity of an RFID solution. The pilot involved tagging of about 60,000 items for the second seasonal collection, and convinced the company to move forward with tagging all items.

Case Study

Monitoring and Controlling Automatic Mixing and Dispensing Machines

As technology advances, textile manufacturing has been transformed from a labor-intensive to a partially or fully automated industry. Automation is significant in all segments of textile production - from spinning to printing, and textile machinery manufacturers are constantly searching for new technologies and automation processes will increase the productivity of their machines. The color paste mixing and dispensing machine is an essential part of the printing and dyeing process. With the advantage of automatically computerized controls and database management, the system can significantly improve its dispensing precision, working efficiency and production quality as well as reducing material consumption.