Download PDF

Syntax Consultancy Enhances Efficiency and Reporting with Bullhorn’s CRM and Marketplace Solutions

Technology Category

- Functional Applications - Manufacturing Execution Systems (MES)

Use Cases

- Additive Manufacturing

- Time Sensitive Networking

Services

- System Integration

The Challenge

Syntax Consultancy, a Derby-based recruitment agency, was facing challenges with its legacy customer relationship management (CRM) system. The system, built by the Syntax IT team in 2004, was no longer sufficient for the growing needs of the agency. The agency required a CRM system with scalable reporting and analysis functionality. The existing system was labor-intensive, leading to inaccuracies in data due to human error. This often resulted in decisions being made based on assumptions rather than concrete numbers. The agency was also spending a significant amount of time correlating multiple spreadsheets from each recruiter. Furthermore, the collation of key performance indicator (KPI) and board-level information was proving to be difficult.

About The Customer

Syntax Consultancy is the largest independent recruitment consultancy in the Midlands, England. The Derby-based agency offers a global recruitment service for IT, engineering, and manufacturing businesses. It specializes in matching highly skilled candidates with organizations that have specific technical requirements. In 2012, Syntax reviewed its CRM and business reporting solutions and decided that both needed to be upgraded. The agency had outgrown its legacy CRM system, which had been built by the Syntax IT team in 2004.

The Solution

After evaluating 12 different Software as a Service (SaaS) offerings, Syntax Consultancy decided to implement Bullhorn as its comprehensive online CRM and reporting solution. This decision was influenced by the additional reporting functionality offered through the Bullhorn Marketplace. The implementation of Bullhorn allowed Syntax to boost productivity and streamline operations into a single system and highly efficient workflow. It also enabled the automation of critical tasks, thereby decreasing error rates and bringing all processes into a web-based system. The new system provided instant access to information, saving time on daily activity and management. It also improved communication within the company as the new SaaS solution enabled the team to easily share resources and expertise from wherever they were working. Syntax was also able to integrate key reporting applications from the Bullhorn Marketplace to measure efficiencies and improve data quality.

Operational Impact

Quantitative Benefit

Related Case Studies.

Case Study

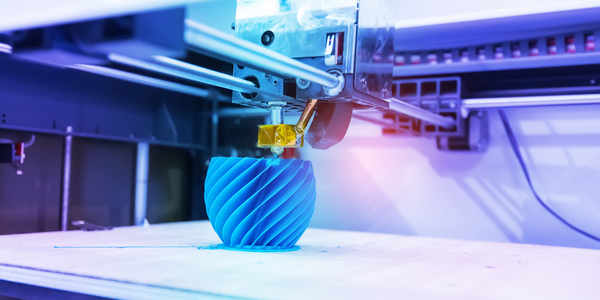

Ford Motor Company on the Road to 3D Manufacturing

To date, key challenges have stood in the way of 3D printing becoming a manufacturing tool for the automaker. The first issue is a fundamental one — conventional 3D printing technologies make parts layer-by-layer, slowly crafting one layer at a time, creating parts that aren’t nearly as robust as those stamped or injection molded. While the slow speed of this process is a major drawback, the bigger problem is that the parts produced are not isotropic and not durable enough to be used in production vehicles. In addition, most parts used in vehicles today must withstand temperature extremes from the hottest desert to the coldest Arctic environments and still maintain their integrity. With only a handful of stock materials available for 3D printers, meeting the automaker’s unique demands has not been possible.

Case Study

3D Printed Prototypes Streamline Equipment Introduction

Vauxhall set out to introduce a modified process hanger with a new part that would be used to support each vehicle body throughout the production process. This part is a critical piece and had to perfectly fit both the machinery and the auto body to create correct clearances and avoid damage during production.

Case Study

Bekaert's Journey to Manufacturing Digitalization with TCS

Bekaert, a major player in the steel wire industry, was facing significant challenges in its manufacturing operations due to outdated data platforms. The company was unable to trace genealogy beyond a week's data and lacked diagnostic analysis of plant operations, which severely hampered decision-making. The absence of automation in benchmarking operations and extensive reporting on plant management further complicated the situation. To enhance efficiency and effectiveness in multiple focus areas, Bekaert needed a modern data platform capable of managing large volumes of data and generating actionable insights. The company aimed to drive quality, overall equipment effectiveness (OEE), and plant productivity based on these insights.

Case Study

Centralizing Data for Improved Efficiency: A Case Study on Malvern Panalytical

Malvern Panalytical, a UK-based hi-tech electronics company, was grappling with the challenge of decentralized data storage. The company had a vast amount of unstructured data scattered across various platforms, from hard drives to emails and floppy disks. This made the data searching process extremely cumbersome and inefficient. The company's rapid growth, from 200 to over 1,000 employees in a decade, and expansion across three continents further exacerbated the need for a more structured and centralized data system. As a company involved in electronics manufacturing and software development, it was crucial for Malvern Panalytical to find a platform that could structure all their data, track all modifications of documents in real time, and provide clear visibility of the internal information flow across all its facilities.