Download PDF

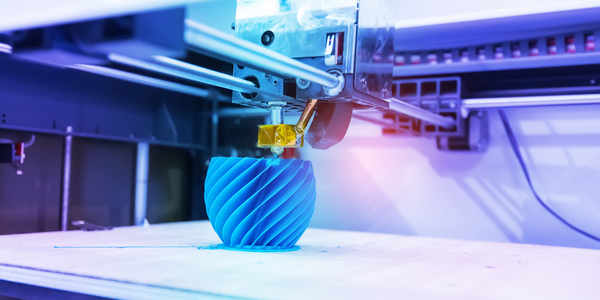

3D Systems

Manufacturing the Future

Overview

HQ Location

United States

Year Founded

1986

Company Type

Public

Revenue

$100m-1b

Employees

1,001 - 10,000

Website

Stock Ticker

NYSE: DDD

Twitter Handle

Company Description

3D Systems provides advanced and comprehensive 3D digital design and fabrication solutions, including 3D printers, print materials and cloud-sourced custom-designed parts. Their comprehensive range of 3D printers is the industry’s benchmark for production-grade manufacturing in aerospace, automotive, patient specific medical device and a variety of accessories.

IoT Solutions

3D Systems unlocks the potential within each of us to transform the way we work, learn and live. As the originator of 3D printing and shaper of the future of 3D solutions, they have spent 30 years of history making 3D technologies accessible, easy to use, productive and gratifying, enabling innovators around the world to transform ideas into tangible outcomes.

3D Systems’ products and services disrupt traditional methods, deliver improved results and empower its customers to manufacture the future now. Their powerful ecosystem transforms entire industries by empowering users to bring their ideas to life using its vast material selection, including plastics, elastomers, metals and bio-compatible materials. 3D Systems’ leading personalized medicine capabilities include end-to-end simulation, training and planning, and printing of patient-specific surgical instruments and medical and dental devices. And their 3D digital design, fabrication and inspection products provide seamless Interoperability and incorporate the latest immersive computing technologies.

3D Systems’ products and services disrupt traditional methods, deliver improved results and empower its customers to manufacture the future now. Their powerful ecosystem transforms entire industries by empowering users to bring their ideas to life using its vast material selection, including plastics, elastomers, metals and bio-compatible materials. 3D Systems’ leading personalized medicine capabilities include end-to-end simulation, training and planning, and printing of patient-specific surgical instruments and medical and dental devices. And their 3D digital design, fabrication and inspection products provide seamless Interoperability and incorporate the latest immersive computing technologies.

Key Customers

GE Consumer & Industrial, Micron Technology, NASA, Sanmina-SCI, Teleflex Marine

IoT Snapshot

3D Systems is a provider of Industrial IoT hardware design and engineering services, and training services, and also active in the aerospace, automotive, education, healthcare and hospitals, life sciences, and retail industries.

Technologies

Use Cases

Functional Areas

Industries

Services

Technology Stack

3D Systems’s Technology Stack maps 3D Systems’s participation in the IoT Technology stack.

-

Devices Layer

-

Edge Layer

-

Cloud Layer

-

Application Layer

-

Supporting Technologies

Technological Capability:

None

Minor

Moderate

Strong

Case Studies.

Case Study

3D Printed Prototypes Streamline Equipment Introduction

Vauxhall set out to introduce a modified process hanger with a new part that would be used to support each vehicle body throughout the production process. This part is a critical piece and had to perfectly fit both the machinery and the auto body to create correct clearances and avoid damage during production.

Case Study

Revolutionizing Medical Training in India: GSL Smart Lab and the LAP Mentor

The GSL SMART Lab, a collective effort of the GSL College of Medicine and the GSL College of Nursing and Health Science, was facing a challenge in providing superior training to healthcare professionals. As clinical medicine was becoming more focused on patient safety and quality of care, the need for medical simulation to bridge the educational gap between the classroom and the clinical environment was becoming increasingly apparent. Dr. Sandeep Ganni, the director of the GSL SMART Lab, envisioned a world-class surgical and medical training center where physicians and healthcare professionals could learn skills through simulation training. He was looking for different simulators for different specialties to provide both basic and advanced simulation training. For laparoscopic surgery, he was interested in a high fidelity simulator that could provide basic surgical and suturing skills training for international accreditation as well as specific hands-on training in complex laparoscopic procedures for practicing physicians in India.

Similar Suppliers.

Supplier

LUTZBOT

Proven TechnologyTens of thousands of people in 85 countries around the world rely on award-winning LulzBot 3D printers, parts, and plastics to get the job done. We proudly serve Fortune 500 companies, NASA and other agencies, small businesses, universities, libraries, and hackers. Open Source Hardware communities are at the core of everything we do. Collaboration enhances every product we offer.Open for AllWe are committed to respecting your freedom. That's why our products come with freely licensed designs, specifications, and documentation so your machine can be understood, modified, and shared as we make improvements together. We partner with leading organizations like Open Source Hardware Association (OSHWA.org) to advance collaborative technology.