Download PDF

FogHorn

Edge Intelligence for Industrial and Commercial IoT

Overview

HQ Location

United States

Year Founded

2014

Company Type

Private

Revenue

$10-100m

Employees

51 - 200

Website

Twitter Handle

Company Description

FogHorn is a leading developer of “edge intelligence” software for industrial and commercial IoT applications. FogHorn’s software platform brings the power of Machine Learning and advanced analytics to the On-Premise edge environment enabling a new class of applications for advanced monitoring and diagnostics, asset performance optimization, operational intelligence and Predictive Maintenance use cases.

IoT Snapshot

FogHorn is a provider of Industrial IoT analytics and modeling, and infrastructure as a service (iaas) technologies, and also active in the automotive, buildings, cities and municipalities, healthcare and hospitals, mining, oil and gas, renewable energy, retail, transportation, and utilities industries.

Technologies

Use Cases

Functional Areas

Industries

Services

Technology Stack

FogHorn’s Technology Stack maps FogHorn’s participation in the analytics and modeling, and infrastructure as a service (iaas) IoT Technology stack.

-

Devices Layer

-

Edge Layer

-

Cloud Layer

-

Application Layer

-

Supporting Technologies

Technological Capability:

None

Minor

Moderate

Strong

Case Studies.

Case Study

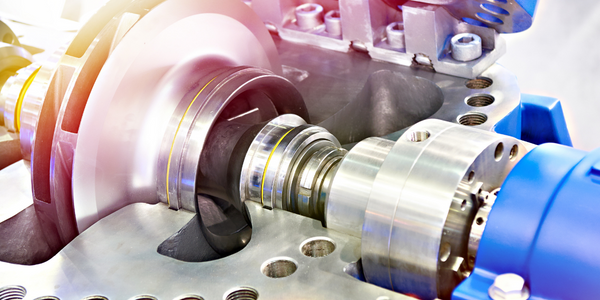

Pump Cavitation Detection

Cavitation is a condition can occur in centrifugal pumps when there is a sudden reduction in fluid pressure. Pressure reduction lowers the boiling point of liquids, resulting in the production of vapor bubbles if boiling occurs. This is more likely to happen at the inlet of the pump where pressure is typically lowest. As the vapor bubbles move towards the outlet of the pump where pressure is higher, they rapidly collapse (return to a liquid state) resulting in shock waves that can damage pump components.

Case Study

GE Detects Early Defects and Improves Capacitor Production

Hard to Detect Capacitor Failure Conditions Reducing Yield, Increasing ScrapGE was facing multi-million-dollar scrap problems due to limited real-time insights into the entire production process. They believed they could significantly improve the yield and reduce the scrap of their manufacturing operation by analyzing a large amount of RFID sensor data being produced by 30+ machines during the production cycle. This included correlating processing data in real-time from several sources to create an edge intelligence layer with FogHorn for real-time condition monitoring throughout the production process. The goal was to identify defects early, quickly determine the root cause, and speed remediation actions to improve yield and reduce scrap costs.

Podcasts.

Similar Suppliers.

Supplier

C3 IoT

C3 IoT provides a full-stack IoT development platform (PaaS) that enables the rapid design, development, and deployment of even the largest-scale big data / IoT applications that leverage telemetry, elastic Cloud Computing, analytics, and Machine Learning to apply the power of predictive analytics to any business value chain. C3 IoT also provides a family of turn-key SaaS IoT applications including Predictive Maintenance, fraud detection, sensor network health, supply chain optimization, investment planning, and customer engagement. Customers can use pre-built C3 IoT applications, adapt those applications using the platform’s toolset, or build custom applications using C3 IoT’s Platform as a Service.Year founded: 2009

Supplier

Altizon Systems

Altizon empowers Industrial Digital Revolutions globally by helping enterprises use Machine Data to drive business decisions. With a global footprint of over 100 enterprise users, Altizon is a leading Industrial IoT platform provider as recognized by Gartner, Forrester, BCG, Frost & Sullivan, and others.