Case Studies.

Our Case Study database tracks 18,927 case studies in the global enterprise technology ecosystem.

Filters allow you to explore case studies quickly and efficiently.

-

(6)

- (4)

- (3)

- (1)

-

(3)

- (3)

-

(2)

- (2)

- (1)

-

(2)

- (1)

- (1)

-

(2)

- (1)

- (1)

- View all 8 Technologies

- (5)

- (3)

- (3)

- (2)

- (2)

- View all 7 Industries

- (5)

- (3)

- (3)

- (2)

- (1)

- View all 5 Functional Areas

- (4)

- (2)

- (1)

- (1)

- (1)

- View all 5 Use Cases

- (2)

- (2)

- (1)

- (14)

Selected Filters

14 case studies

|

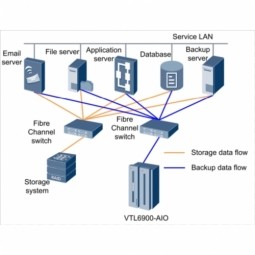

New Backup System Solves Legacy Problems

Huawei

Midea's outdated IT infrastructure in some sites could no longer keep pace with company's growth, putting operational reliability at risk. The legacy data backup system could not backup at some production sites. Some sites were still using the x86 server’s local hard disks as the backup media, resulting in limited backup size. The existing backup system was inefficient.

|

|

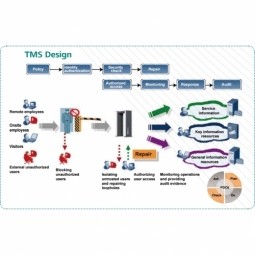

Carmaker Holds the Keys to Network Security

Huawei

FAW-Volkswagen Automotive Company (FAW-VW) required a high number of communication terminals due to its rapid development. FAW-VW also faced challenges in security management, IT Operation and Maintenance (O&M) costs, and employees work efficiency. FAW-VW needed terminal security protection with reliable access control and user rights management and comprehensive network protection.

|

|

NB-IoT Boosts Smart Bike Sharing

Huawei

Ofo Bike sharing company wanted to improve its user experience by providing seamless network connectivity to its users where they can locate bikes and pedal away quickly exactly when and where they need one, but challenge is to avoid frustration if user finds difficulties in finding bikes, unlocking the bikes and making payments

|

|

New smart in-car features with Connected Vehicle Modular Platform (CVMP)

Huawei

Despite keeping overseas Eurasia and Latin America growth on track as shown in Q4 2017 results, PSA group was faced with an internal R&D dilemma at its subsidiary Opel whilst its sales in China have dropped by almost half, to 387,000, all in the same year. Seeing that the Chinese passenger-car market on the other hand has surged nearly a quarter, from 19.7 million in 2014 to 24.7 million in 2017, PSA group saw the need to create increasingly connected vehicles to attract consumers with a strong appetite for 5G. The main challenge remains that PSA's product lineup still has overlapping and outdated models, including an earlier version of the Peugeot 3008 and several Citroen and DS models, all of which are sold only in China.

|

|

Smart Liaoyuan: The First Smart City in Northeast China

Huawei

• Liaoyuan's demands for building a high-quality smart city, covering multiple sectors, including city management, emergency command, public security, and health care. • Unable to connect different functional sectors for lack of a unified information system; without IoT, city management is restricted to manual intervention.

|

|

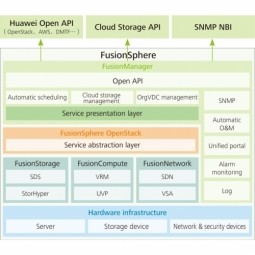

Drug Maker Takes the Right Prescription

Huawei

China Pharm decided to build a cloud-based platform to support the requirements of IT planning for the next five to ten years which includes a dynamic and scalable mail resource pool platform. The platform needed to have the following functions: all nodes support redundancy, ensuring service continuity and good user experience, simple and easy-to-use user interfaces for end users and administrators and good compatibility and supports smooth capacity expansion.

|

|

Karamay: Building the Safest City

Huawei

• The non-smart legacy surveillance platform lacks video processing capability, resulting in unclear images and low work efficiency • The existing information systems are isolated, making it difficult to centrally manage video surveillance products and achieve multi-platform interconnection and collaboration. As a result, intelligent analysis of massive data and effective data mining are impeded.

|

|

Longyan Smart Hospital: Secure, Efficient and Green

Huawei

• Aiming to be the model hospital in Fujian province, Longyan People Hospital plans to build a "digital hospital" in its new building, providing mobile ward rounds, desktop cloud, and Hospital Information System (HIS) cloud, as well as service level disaster recovery with the old building • Need to migrate the existing applications, such as HIS, Laboratory Information System (LIS), Picture Archiving and Communication System (PACS), and resident health system, to the new building to achieve desktop cloud

|

|

Going Mobile: Business on the Go

Huawei

Haier is building a mobile application platform where all mobile applications running on this platform must be designed with unified security, architecture, management, and platform support capabilities. This new platform also must incorporate Haier's IT applications with smart devices.

|

|

Unified Quality Inspection Standards for Brand Owners and Multiple Factories

Huawei

In the 3C industry and the automotive industry, the consistency of the measurement standards of upstream parts processing manufacturers and OEMs is important. How to quickly and efficiently sample the quality of parts according to the standards after OEM manufacturers receive parts, digitize the test results in real-time and share with other business systems and make them traceable, are common pain points in the industry.

|

|

3C Product Online Appearance Quality Inspection

Huawei

For a 3C product supply chain enterprise, the monthly labour cost of manual visual inspection exceeds 2 million, the proportion of quality inspection personnel accounts for 20%~40%, and there are quality problems such as missed inspections. At present, manual quality inspection is faced with the problems of quality, cost, response to special scenarios, and information integration. The details are as follows:Quality: The subjective factor of manual quality inspection has a great influence on the judgment result, and there will be a problem of missed inspection based on visual fatigue; Production status of a 3C product supply chain enterprise.Information integration: There is no effective accumulation and utilization of production data, and subsequent process reengineering and quality analysis cannot be promoted, and the adaptation to automated production processes is weak.Cost: The turnover of personnel is high, resulting in high training and labour costs, and it is difficult to recruit workers.Efficiency: Traditional machine vision uses programmed computing logic for visual inspection, which has poor anti-interference ability for such complex surface inspection, high false detection, and heavy workload for personnel re-judgment.

|

|

Error Proofing Inspection after Product Assembly

Huawei

In the assembly workshop of an automobile OEM, the last process of automobile production still needs to rely on a lot of manpower to assemble the body. For the scene of lamp inspection, due to the mixed production inspection, the inspectors completely rely on experience to inspect the model. In addition, due to the serious light interference on the assembly line, the inspectors also need to avoid the interference of external light sources on the detection of vehicle lights, and the detection cycle is short, which also has high requirements on the inspection speed of the inspectors.At present, traditional manual quality inspection faces the problems of quality, special scene response and information integration:1 Quality: In manual quality inspection, experienced quality inspectors are required to know exactly which parts are equipped with which models based on 20+ types of vehicles. The requirements for human experience are high, and new employees are unfamiliar with models. There will be problems with missed inspections.2 In the case of a strong light source for a long time, it is necessary to take relevant human protection to prevent the eyes from being exposed to the light source for a long time.3 Information integration: at present, it is impossible to match the material of the model and the lamp, and the material deviation cannot be traced.

|

|

5G+AI: Production Process Bottleneck Analysis

Huawei

In the product assembly operation involving people in the factory production line, the general actions usually include fixed operation procedures such as: reaching out, grasping, moving objects, assembling. After the operator works for a long time or is disturbed, the assembly action will be omitted and it might cause misoperation. It's also necessary to identify the problems existing in the action through action analysis so that the sequence and method of the action can be improved.

|

|

5G+AI: Intelligent Sorting of Items in the Production Process

Huawei

In many industries such as industrial manufacturing and logistics, there are many needs for identifying, detecting and classifying products or objects. Traditional detection methods based on artificial vision are prone to fatigue, and cannot always guarantee high detection efficiency, and due to the physiological limit of the human eye itself, it is difficult to achieve high standards in terms of speed and accuracy. Therefore, the traditional manual detection method restricts the development and improvement of the productivity level and has been difficult to meet the needs of production. More and more sorting robots based on machine vision are widely used in various industrial production lines. That is, the target image information is obtained through the industrial camera, and the sorting of the grabbed target is completed. The traditional industrial robot visual sorting system uses classical computer vision theory, such as invariant distance, template matching, SURF feature and other algorithms to identify and locate workpieces, which has higher requirements on the scene environment, workpiece shape and background colour. The workpieces and objects on the on-site conveyor belt may have complex shapes and different postures and are densely placed together. In this case, the classical visual recognition and positioning algorithms cannot meet the requirements of high recognition rate and high precision.

|