Download PDF

Industrial Vision Systems

Overview

HQ Location

United Kingdom

Year Founded

2000

Company Type

Private

Revenue

< $10m

Employees

11 - 50

Website

Company Description

Industrial Vision Systems Ltd (IVS®) is a major manufacturer of machine vision and Artificial Intelligence products whose name is synonymous with innovative image processing systems for quality control, code reading, guiding and identification. By combining software expertise with application integration, we offer a unique service - that of vision system manufacturer and vision system integrator.

IoT Solutions

IVS' vision inspection machines, machine vision products, special purpose vision machines, smart camera systems and peripheral vision equipment. Their machine vision systems are some of the most innovative and advanced on the market today.

Key Customers

IVS' products are used all over the world in automated production processes for quality control, inspection, guidance, identification, measurement, tracking and counting - in many diverse industries.

IoT Snapshot

Industrial Vision Systems is a provider of Industrial IoT sensors, and robots technologies, and also active in the food and beverage, and packaging industries.

Technologies

Use Cases

Functional Areas

Industries

Technology Stack

Industrial Vision Systems ’s Technology Stack maps Industrial Vision Systems ’s participation in the sensors, and robots IoT Technology stack.

-

Devices Layer

-

Edge Layer

-

Cloud Layer

-

Application Layer

-

Supporting Technologies

Technological Capability:

None

Minor

Moderate

Strong

Case Studies.

Case Study

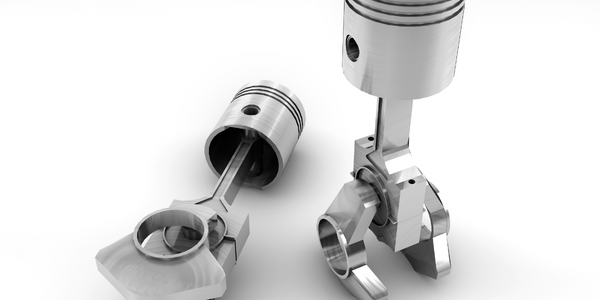

Automated Inspection of Axial Piston Motors

Earth moving machines require an immense energy source to provide the power they need for use within civil engineering works. ‘Hydraulic Motors’ allow this power to be applied to enable the machines movement and in addition ‘Control Valves’ also provide the operator with the precise feel and control required to undertake the necessary tasks needed for such machines, including trenching, rock breaking and demolition. These same motors are also used in cranes, wheel loaders and general construction equipment. Though not a new product, the designs of such motors and control valves have been around a few decades, the overall method for manufacture has changed rapidly over the last few years to take account of the need for more modular designs, manufacture and just-in-time manufacturing. Kawasaki Precision Machinery (UK) Ltd based in Plymouth, UK is one of the leading manufacturers of such motors and pumps. They approached Industrial Vision Systems Ltd to come up with a solution to provide automated inspection of such pumps for their semi-automated assembly process. The pumps requiring inspection are at a sub-assembly stage when they are due for the inspection process to take place. Due to the highly modular nature of the construction each part of the pump can have many different derivatives which overall have a different effect on the pump in industrial use. It is therefore critical for the manufacturing process to check all components are the correct type and number for the construction of the pump to begin. Once built it is difficult and costly to rework such units if a fault is detected later in the manufacturing process, therefore automated visual inspection is critical for the success in building quality motors and pumps.

Similar Suppliers.

Supplier

Framos

Framos GmbH offers a portfolio of vision services and components to enable machines and imaging and vision technologies.The company has been a leading global supplier of imaging products, custom vision solutions and OEM services and as a modern family business. It has assisted its customers since 1981 in the development of vision technologies.

Supplier

Fisher Smith

Founded in 2004 as FS Systems, and now Fisher Smith, we have over 50 combined years of experience of machine vision and Industrial Control Systems. Our knowledge and technical abilities has enabled us to develop two key software products, RoboVis® and GenVis. Written and developed in house by Iain Smith with usability and flexibility in mind, both products have become mature and stable machine vision platforms.

Supplier

XARION Laser Acoustics

XARION Laser Acoustics is a provider of unique, laser-based acoustic sensors. The membrane-free optical microphone uses an IP-protected principle of operation: it detects sound based on its ability to change the speed of light. Since no mechanically movable or deformable parts are involved in this approach, the sensor comes with a linear frequency response free from mechanical resonances. The microphone shows an unprecedented frequency bandwidth exceeding state of the art solutions by a factor of ten.