下载PDF

Industrial Vision Systems

概述

公司介绍

Industrial Vision Systems Ltd (IVS®) 是机器视觉和人工智能产品的主要制造商,其名称是用于质量控制、代码读取、引导和识别的创新图像处理系统的代名词。通过将软件专业知识与应用程序集成相结合,我们提供独特的服务——视觉系统制造商和视觉系统集成商。

物联网解决方案

IVS的视觉检测机、机器视觉产品、专用视觉机、智能相机系统和周边视觉设备。他们的机器视觉系统是当今市场上最具创新性和最先进的系统。

主要客户

IVS 的产品在世界各地用于质量控制、检查、引导、识别、测量、跟踪和计数的自动化生产过程中 - 在许多不同的行业中。

物联网应用简介

技术栈

Industrial Vision Systems 的技术栈描绘了Industrial Vision Systems 在传感器, 和 机器人等物联网技术方面的实践。

-

设备层

-

边缘层

-

云层

-

应用层

-

配套技术

技术能力:

无

弱

中等

强

实例探究.

Case Study

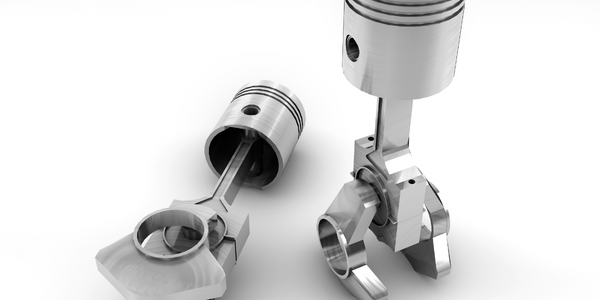

Automated Inspection of Axial Piston Motors

Earth moving machines require an immense energy source to provide the power they need for use within civil engineering works. ‘Hydraulic Motors’ allow this power to be applied to enable the machines movement and in addition ‘Control Valves’ also provide the operator with the precise feel and control required to undertake the necessary tasks needed for such machines, including trenching, rock breaking and demolition. These same motors are also used in cranes, wheel loaders and general construction equipment. Though not a new product, the designs of such motors and control valves have been around a few decades, the overall method for manufacture has changed rapidly over the last few years to take account of the need for more modular designs, manufacture and just-in-time manufacturing. Kawasaki Precision Machinery (UK) Ltd based in Plymouth, UK is one of the leading manufacturers of such motors and pumps. They approached Industrial Vision Systems Ltd to come up with a solution to provide automated inspection of such pumps for their semi-automated assembly process. The pumps requiring inspection are at a sub-assembly stage when they are due for the inspection process to take place. Due to the highly modular nature of the construction each part of the pump can have many different derivatives which overall have a different effect on the pump in industrial use. It is therefore critical for the manufacturing process to check all components are the correct type and number for the construction of the pump to begin. Once built it is difficult and costly to rework such units if a fault is detected later in the manufacturing process, therefore automated visual inspection is critical for the success in building quality motors and pumps.

同类供应商.

Supplier

Framos

Framos GmbH offers a portfolio of vision services and components to enable machines and imaging and vision technologies.The company has been a leading global supplier of imaging products, custom vision solutions and OEM services and as a modern family business. It has assisted its customers since 1981 in the development of vision technologies.

Supplier

Fisher Smith

Founded in 2004 as FS Systems, and now Fisher Smith, we have over 50 combined years of experience of machine vision and Industrial Control Systems. Our knowledge and technical abilities has enabled us to develop two key software products, RoboVis® and GenVis. Written and developed in house by Iain Smith with usability and flexibility in mind, both products have become mature and stable machine vision platforms.

Supplier

XARION Laser Acoustics

XARION Laser Acoustics is a provider of unique, laser-based acoustic sensors. The membrane-free optical microphone uses an IP-protected principle of operation: it detects sound based on its ability to change the speed of light. Since no mechanically movable or deformable parts are involved in this approach, the sensor comes with a linear frequency response free from mechanical resonances. The microphone shows an unprecedented frequency bandwidth exceeding state of the art solutions by a factor of ten.