TEKNOPAR Industrial Automation

TEKNOPAR Industrial AutomationTEKNOPAR, founded in 1996, is one of the leading providers of automation systems and solutions in Turkey for industrial facilities, energy, mobility sectors. Through the development of its engineering and production infrastructure, the company has extended its sphere of activity to provide customers with a wide range of services and end-to-end solutions where integrated applications of mechanical, hydraulic, automation, control and information technologies have been supplied. By combining information technologies with control, automation, robotics, and operational technologies, our company develops industrial communication systems, servo-controlled motion systems, Embedded Software, industrial software and data processing platforms. This blend of expertise is further enhanced by an expansive manufacturing capability, positioning TEKNOPAR as a versatile partner in industrial innovation.

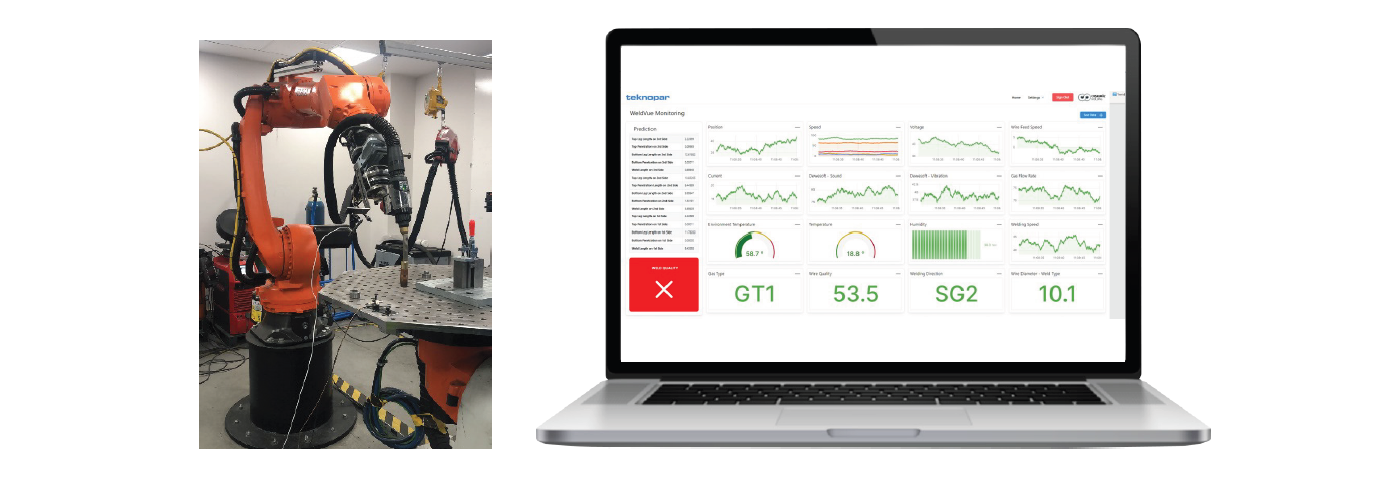

TIA Platform stands at the forefront of the Industrial Internet of Things (IIoT) revolution, offering an unmatched solution designed to address the pressing needs of the manufacturing sector for real-time production visibility and streamlined communication between operators and management. Originating from a vision to transition manufacturing from a reactive to a predictive modality, TIA Platform utilizes the most advanced real-time analytics to power this transformation.

Empowering the Digital Manufacturing Era:

At its essence, TIA Platform is more than just an IIoT analytics and machine monitoring platform—it's a catalyst for Digital Transformation within the manufacturing landscape. By offering real-time insights into production data, immediate notifications, and historical analytics, TIA Platform empowers workers at all levels to make swift, informed decisions, enhancing operational agility and efficiency.

Streamlining IoT Integration for Peak Efficiency:

Recognizing the complexity of IoT integration in manufacturing environments, TIA Platform simplifies this process, offering a straightforward, user-friendly platform that champions manufacturing efficiency. Its ease of integration removes barriers, allowing manufacturers to rapidly achieve operational excellence.

Advanced Monitoring and Comprehensive Reporting:

TIA Platform distinguishes itself through superior monitoring capabilities and robust reporting functionalities. It delivers in-depth insights into machine conditions, production metrics, work-order statuses, and quality control measures. Featuring real-time dashboards, OEE reports, job analytics, and detailed downtime analysis segmented by shift, machine, and job/part, the platform provides a detailed lens through which managers can pinpoint production bottlenecks and evaluate the effectiveness of process improvements.

Flexibility with Cloud and On-Premise Solutions:

Designed for maximum accessibility, TIA Platform's secure, mobile-friendly cloud application ensures that manufacturing data is readily available, with no need for on-site servers. This approach guarantees automatic updates while reducing IT overhead. Alternatively, for organizations preferring localized data control, TIA Platform offers an On-Premise solution, where data is securely stored on company-owned hardware, ensuring both flexibility and security in data management.

Shaping the Future of Smart Manufacturing:

As the manufacturing industry advances towards a digitally integrated future, TIA Platform is paving the way. The platform not only meets the immediate needs for real-time production monitoring and strategic decision-making but also lays the groundwork for implementing Predictive Maintenance and operational forecasting. With TIA Platform, manufacturers are positioned to leap from reactive measures to proactive strategies, unlocking unprecedented levels of efficiency, innovation, and competitive advantage in the manufacturing process.

Begin your journey of Digital Transformation with TIA Platform and set new benchmarks in manufacturing efficiency, predictive analytics, and operational foresight. Join us in redefining the future of manufacturing—where digital intelligence meets operational excellence.

American Spiral Weldpipe Co (ASWP), Silverline, Coşkunöz, Noksel, ASELSAN

-

Devices Layer

-

Edge Layer

-

Cloud Layer

-

Application Layer

-

Supporting Technologies

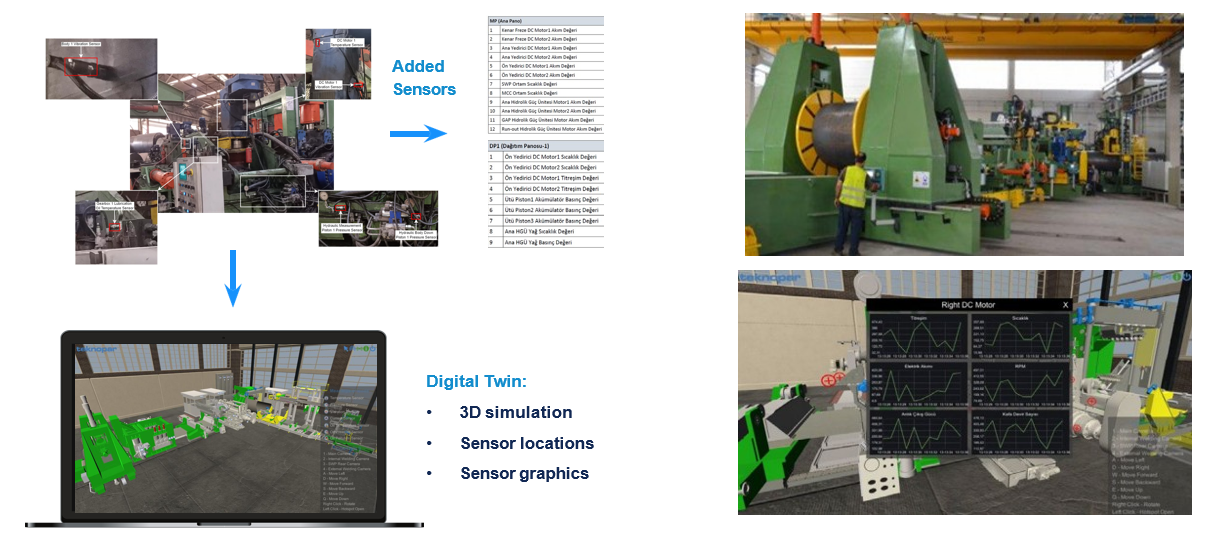

Case Studies.