下载PDF

Flexibility and Cost Efficiency in Automotive Development: A Case Study on HBPO GmbH

技术

- 分析与建模 - 数字孪生/模拟

- 机器人 - 自动导引车 (AGV)

适用行业

- 汽车

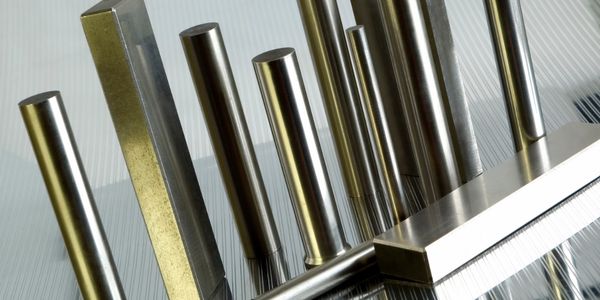

- 金属

适用功能

- 采购

- 产品研发

用例

- 交通模拟

- 虚拟现实

服务

- 系统集成

- 测试与认证

挑战

HBPO GmbH 是一家由全球汽车零部件领导者组成的合资企业,专门为汽车制造商提供完整前端模块的开发、组装和物流。挑战在于这些模块的复杂性,需要大量组件,如前灯、散热器格栅、保险杠、前端支架以及车辆空调、发动机冷却和碰撞管理系统的组件。根据客户要求和预设规格,HBPO 涵盖组装、开发和系统集成项目。前端模块的开发和组装需要各种各样的仿真应用,例如结构分析、成型仿真、虚拟碰撞测试、材料数据管理等。需要许多不同的软件工具,其中一些很少使用。为了涵盖所有这些学科,对于 HBPO 来说至关重要的是保持尽可能低的开发成本并在需要时能够访问所需的工具。

关于客户

HBPO GmbH 是一家合资企业,由照明和电子产品 (Hella KGaA Hueck & Co.)、车辆空调和发动机冷却 (Behr GmbH & Co. KG) 以及喷漆车身外部部件和塑料系统领域的全球创新和市场领导者运营(塑料 Omnium 汽车外饰 SAS)。该合资公司为汽车制造商开发、制造和分销智能前端模块。 HBPO 凭借技术先进且具有经济吸引力的解决方案在市场上树立了新的基准,是全球唯一一家专门从事完整前端模块的开发、组装和物流的系统集成商。 2011年销售额总计10.5亿欧元。 HBPO 在全球拥有 1,400 多名员工,目前每年组装约 440 万个前端。

解决方案

HBPO 在其模块开发中使用最先进的工具,以最短的开发时间和成本保证最高的质量。这些工具由 Altair、Altair 合作伙伴联盟 (APA) 和其他 CAE 提供商提供。 HBPO 的工程师可以使用公司提供的浮动许可证来访问 HyperWorks 以及 Altair 联盟合作伙伴提供的一套第三方应用程序。这些 HyperWorks 单元的灵活性使用户能够访问市场上最大、最完整的 CAE 应用程序套件,无需增加成本,也无需长期承诺。随着 APA 不断扩大其软件工具的范围,客户的投资回报率也不断增长。 HBPO 通过 Altair 合作伙伴联盟访问的工具包括用于模具仿真的 Moldex3D、用于材料数据管理和材料选择的 KEY to METALS、用于乘员安全分析和设计优化的 MADYMO。在 HyperWorks Suite 中,该公司使用 HyperMesh、HyperView 和 BatchMesher 进行预处理和后处理任务,使用 HyperForm 进行成形模拟,使用 Result Mapper 映射模拟结果,使用 HyperStudy 和 HyperGraph 进行后处理,再加上 OptiStruct 和 RADIOSS 进行优化,线性和非线性结构分析。

运营影响

数量效益

相关案例.

Case Study

Goldcorp: Internet of Things Enables the Mine of the Future

Goldcorp is committed to responsible mining practices and maintaining maximum safety for its workers. At the same time, the firm is constantly exploring ways to improve the efficiency of its operations, extend the life of its assets, and control costs. Goldcorp needed technology that can maximize production efficiency by tracking all mining operations, keep employees safe with remote operations and monitoring of hazardous work areas and control production costs through better asset and site management.

Case Study

KSP Steel Decentralized Control Room

While on-site in Pavlodar, Kazakhstan, the DAQRI team of Business Development and Solutions Architecture personnel worked closely with KSP Steel’s production leadership to understand the steel production process, operational challenges, and worker pain points.

Case Study

Bluescope Steel on Path to Digitally Transform Operations and IT

Increasing competition and fluctuations in the construction market prompted BlueScope Steel to look toward digital transformation of its four businesses, including modern core applications and IT infrastructure. BlueScope needed to modernize its infrastructure and adopt new technologies to improve operations and supply chain efficiency while maintaining and updating an aging application portfolio.

Case Study

Integral Plant Maintenance

Mercedes-Benz and his partner GAZ chose Siemens to be its maintenance partner at a new engine plant in Yaroslavl, Russia. The new plant offers a capacity to manufacture diesel engines for the Russian market, for locally produced Sprinter Classic. In addition to engines for the local market, the Yaroslavl plant will also produce spare parts. Mercedes-Benz Russia and his partner needed a service partner in order to ensure the operation of these lines in a maintenance partnership arrangement. The challenges included coordinating the entire maintenance management operation, in particular inspections, corrective and predictive maintenance activities, and the optimizing spare parts management. Siemens developed a customized maintenance solution that includes all electronic and mechanical maintenance activities (Integral Plant Maintenance).

Case Study

RobotStudio Case Study: Benteler Automobiltechnik

Benteler has a small pipe business area for which they produce fuel lines and coolant lines made of aluminum for Porsche and other car manufacturers. One of the problems in production was that when Benteler added new products, production had too much downtime.