下载PDF

Scaling Boldify's Online Business with Skubana

技术

- 功能应用 - 库存管理系统

- 平台即服务 (PaaS) - 应用开发平台

适用功能

- 采购

- 销售与市场营销

用例

- 拣选/分拣/定位

- 视觉质量检测

服务

- 系统集成

- 测试与认证

挑战

Boldify 是一个美容和个人护理品牌,在扩大在线业务方面面临着挑战。他们正在寻找一种强大的库存和订单解决方案,能够与现有的 Amazon 和 Shopify 渠道无缝集成,并适应未来扩展到 Target 等批发渠道的需求。联合创始人迈克·维斯科维奇曾尝试过其他平台,但由于缺乏优质的客户支持而不满意。他需要一个平台,不仅能够快速轻松地集成 Amazon 和 Shopify,还能提供优质的客户支持。 Boldify的业务涉及美国制造的核心产品和中国制造的盒子,这些产品被发送到FBA。这种设置似乎让其他支持团队感到困惑,增加了公司面临的挑战。

关于客户

Boldify 是一个美容和个人护理品牌,团队规模为 1-25 人。该公司专门生产治疗脱发的产品,这是许多人面临的常见问题。 Boldify 正在寻求扩大其在线业务并为应对扩张的挑战做好准备。他们需要一个既能与现有的 Amazon 和 Shopify 渠道无缝集成,又能适应未来扩展到 Target 等批发渠道的平台。该公司的业务涉及美国制造的核心产品和中国制造的盒子,这些产品被发送到FBA。 Boldify 的联合创始人 Mike Viskovich 和运营经理 Luciana Fistarol 在寻找合适的平台以及随后将 Skubana 整合到他们的运营中发挥了重要作用。

解决方案

Boldify 在 Skubana 中找到了解决方案,该平台不仅能够与现有渠道很好地集成,而且还提供优质的客户支持。 Skubana 的团队能够理解并回答 Boldify 的库存相关问题,这与 Viskovich 在其他平台上的经历形成鲜明对比。 Skubana 的结构和布局正是 Boldify 所寻求的。该平台的 Orderbots 和预构建的集成(如亚马逊)无缝运行。 Skubana for Boldify 最有价值的功能是其开放的 API。 Boldify 运营经理 Luciana Fistarol 对该平台的灵活性表示赞赏。 Skubana 的开放 API 允许 Boldify 解释来自 Shopify、Amazon 和三个不同 3PL 的数据,并快速更改订单规则。此功能使 Boldify 能够适应日益增加的复杂性以及随着业务增长而快速改变策略的需要。

运营影响

数量效益

相关案例.

Case Study

DHL Supply Chain Growing Use of AR Glasses

A picker with an RF scanner is constantly looking at the gun to get pick commands, hitting the confirm button and doing things in sequential fashion which is time consuming. Warehouse operations costs add up to 20% of the total logistics costs for DHL.

Case Study

Rapid and Simple Installation Provides Access to Critical Data

The customer needed to monitor non-contact alignment and non-contact process temperature in different positions along a 100-meter production line. Space around the line is tight and operators and forklift trucks are passing by constantly. Installation of correctly routed cables from sensors back to the control station would have been expensive and would have taken too long and caused too much disruption to ongoing operations.

Case Study

Real-Time IoT Tracking and Visualization Improve Manufacturing

Shimane Fujitsu, a wholly-owned subsidiary of Fujitsu and a leading manufacturer of business notebooks and tablets, set out to improve processes where factory inspections found product errors. Prioritizing product rework based on shipping date was challenging, and it caused Shimane Fujitsu to incur additional shipping fees. The company needed a way to collect data to better track the location of products in the rework cycle as well as monitor progress in real time. The collected data would also help process analysis for future improvements.

Case Study

Automatic Vision Inspection Solution for Product Traceability

With greater market demand for food safety, traceability is receiving increasingly more attention in the food and beverage industry as well as the packaging industry. One of the world's leading providers of beverage containers required a system to identify bar codes and alphanumeric characters on ink-jet-printed labels at a run rate of 7 units and minimum 99.9% accuracy. Since there were few engineers in the factory, the customer sought to implement a reliable system with an easy-to-use GUI for workers with a less technical background.

Case Study

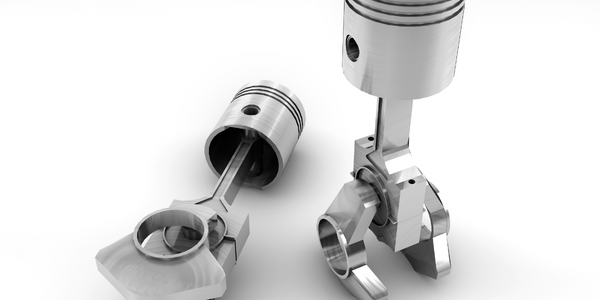

Automated Inspection of Axial Piston Motors

Earth moving machines require an immense energy source to provide the power they need for use within civil engineering works. ‘Hydraulic Motors’ allow this power to be applied to enable the machines movement and in addition ‘Control Valves’ also provide the operator with the precise feel and control required to undertake the necessary tasks needed for such machines, including trenching, rock breaking and demolition. These same motors are also used in cranes, wheel loaders and general construction equipment. Though not a new product, the designs of such motors and control valves have been around a few decades, the overall method for manufacture has changed rapidly over the last few years to take account of the need for more modular designs, manufacture and just-in-time manufacturing. Kawasaki Precision Machinery (UK) Ltd based in Plymouth, UK is one of the leading manufacturers of such motors and pumps. They approached Industrial Vision Systems Ltd to come up with a solution to provide automated inspection of such pumps for their semi-automated assembly process. The pumps requiring inspection are at a sub-assembly stage when they are due for the inspection process to take place. Due to the highly modular nature of the construction each part of the pump can have many different derivatives which overall have a different effect on the pump in industrial use. It is therefore critical for the manufacturing process to check all components are the correct type and number for the construction of the pump to begin. Once built it is difficult and costly to rework such units if a fault is detected later in the manufacturing process, therefore automated visual inspection is critical for the success in building quality motors and pumps.

Case Study

Parts Quality Gets Robotic Boost

When manufacturers, such as the world's top car makers and automotive parts suppliers, produce components in their factories, traditional QA testing has been limited to verifying the quality of random parts pulled off the line throughout the day.It was time consuming to perform the detailed tests required, and defective parts could get through despite randomized tests.If a defective part caused a recall or accident, manufacturers could face costly litigation or irreparable damage to their reputation.